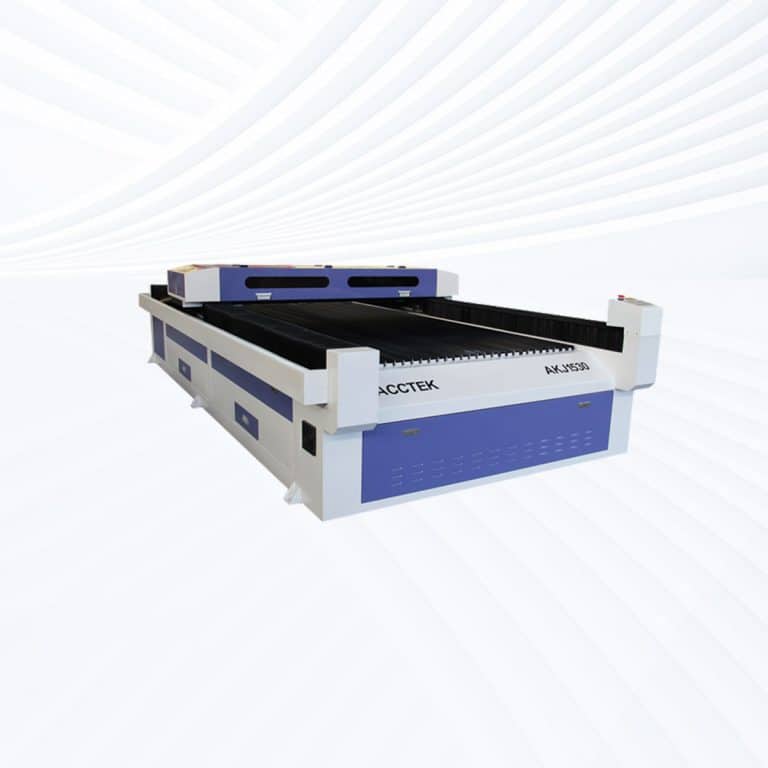

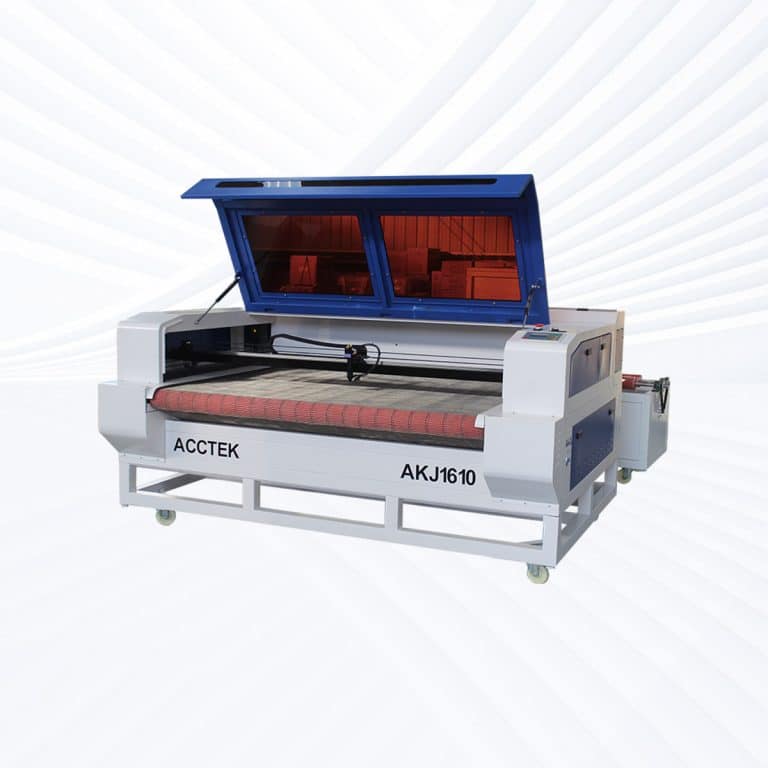

Product Introduction

CO2 Laser Cutting Capabilities

| Material Type | 60W | 80W | 90W | 100W | 130W | 150W | 180W | 220W | 260W | 300W | 500W | 600W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Acrylic | 0-8mm | 0-10mm | 0-12mm | 0-15mm | 0-18mm | 0-20mm | 0-22mm | 0-25mm | 0-28mm | 0-30mm | 0-35mm | 0-40mm |

| Plywood | 0-6mm | 0-8mm | 0-9mm | 0-10mm | 0-12mm | 0-15mm | 0-15mm | 0-18mm | 0-20mm | 0-22mm | 0-25mm | 0-28mm |

| MDF | 0-5mm | 0-6mm | 0-8mm | 0-9mm | 0-12mm | 0-15mm | 0-15mm | 0-18mm | 0-20mm | 0-22mm | 0-25mm | 0-25mm |

| Solid Wood | 0-5mm | 0-6mm | 0-8mm | 0-10mm | 0-12mm | 0-15mm | 0-15mm | 0-18mm | 0-20mm | 0-22mm | 0-25mm | 0-25mm |

| Bamboo Board | 0-5mm | 0-6mm | 0-8mm | 0-10mm | 0-12mm | 0-15mm | 0-15mm | 0-18mm | 0-20mm | 0-22mm | 0-25mm | 0-25mm |

| Leather | 0-4mm | 0-5mm | 0-5mm | 0-6mm | 0-6mm | 0-8mm | 0-8mm | 0-8mm | 0-10mm | 0-10mm | 0-12mm | 0-12mm |

| Textile | Any Cutting | Any Cutting | Any Cutting | Any Cutting | Any Cutting | Any Cutting | Any Cutting | Any Cutting | Any Cutting | Any Cutting | Any Cutting | Any Cutting |

| Rubber | 0-3mm | 0-4mm | 0-5mm | 0-5mm | 0-6mm | 0-6mm | 0-8mm | 0-8mm | 0-8mm | 0-10mm | 0-10mm | 0-10mm |

| EVA | 0-5mm | 0-6mm | 0-8mm | 0-10mm | 0-12mm | 0-15mm | 0-15mm | 0-18mm | 0-20mm | 0-25mm | 0-30mm | 0-30mm |

| Cardboard | 0-3mm | 0-4mm | 0-4mm | 0-5mm | 0-6mm | 0-6mm | 0-8mm | 0-8mm | 0-8mm | 0-10mm | 0-10mm | 0-10mm |

| Cork Sheet | 0-3mm | 0-4mm | 0-5mm | 0-5mm | 0-6mm | 0-6mm | 0-8mm | 0-8mm | 0-8mm | 0-10mm | 0-10mm | 0-10mm |

| ABS | 0-3mm | 0-4mm | 0-5mm | 0-6mm | 0-8mm | 0-8mm | 0-10mm | 0-10mm | 0-12mm | 0-12mm | 0-15mm | 0-15mm |

| Delrin | 0-3mm | 0-4mm | 0-5mm | 0-6mm | 0-8mm | 0-8mm | 0-10mm | 0-10mm | 0-12mm | 0-12mm | 0-15mm | 0-15mm |

| Foam Board | 0-5mm | 0-6mm | 0-8mm | 0-10mm | 0-12mm | 0-15mm | 0-18mm | 0-20mm | 0-25mm | 0-25mm | 0-30mm | 0-30mm |

| PCB | 0-1mm | 0-1.5mm | 0-2mm | 0-2mm | 0-3mm | 0-3mm | 0-3mm | 0-4mm | 0-4mm | 0-5mm | 0-5mm | 0-5mm |

| Laminates | 0-3mm | 0-4mm | 0-5mm | 0-6mm | 0-8mm | 0-8mm | 0-10mm | 0-10mm | 0-12mm | 0-12mm | 0-15mm | 0-15mm |

| Stone | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only |

| Ceramic | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only |

Compatible Materials

- Rubber

- Delrin

- ABS Plastic

- Polystyrene

- Polycarbonate

- PETG

- EVA Foam

- Neoprene

- Mylar

- Nylon

- Canvas

- Suede

- Fleece

- Cardstock

- Veneer

- Latex

- Foam Board

- Pressboard

- Melamine

- Carbon Fiber

- Linoleum

- Birch Plywood

- Walnut Plywood

- Alder Wood

- Basswood

- Chipboard

- Hardboard

- Synthetic Felt

- Wool Fabric

- Polyurethane Foam

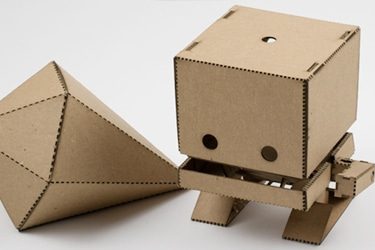

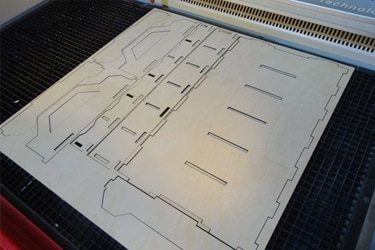

Application of 60W CO2 Laser Cutting Machines

Customer Testimonials

Comparison VS Other Cutting Technologies

| Comparison Item | CO2 Laser Cutting | CNC Routing | Knife Cutting | Waterjet Cutting |

|---|---|---|---|---|

| Cutting Principle | Uses a focused laser beam to vaporize material | Uses rotating cutting bits to remove material | Uses a sharp blade to slice through material | Uses a high-pressure jet of water (with or without abrasive) |

| Suitable Materials | Non-metals like wood, acrylic, leather, fabric, rubber | Wood, plastics, composites, soft metals | Soft materials like foam, leather, textiles, and paper | Almost all materials, including metal, stone, glass, and composites |

| Cutting Precision | Very high (±0.05 mm) | Moderate (±0.2 mm) | Moderate to high (±0.1 mm) | High (±0.1 mm) |

| Edge Quality | Smooth, sealed edges (especially on acrylic and wood) | May require sanding or finishing | Clean for soft materials | Smooth but can be slightly rough on thick cuts |

| Cutting Speed | Fast for thin to medium materials | Slower due to mechanical resistance | Fast on soft materials | Slower, especially for thick or hard materials |

| Maintenance | Low — no physical contact with material | Medium — bits wear out regularly | Low — blades replaced periodically | High — pumps, nozzles, and abrasive handling required |

| Noise Level | Quiet operation | Noisy (due to motor and bit contact) | Very quiet | Very loud (requires sound enclosure) |

| Heat Effect | Generates localized heat (may char some materials) | Minimal heat | No heat | No heat |

| Tool Wear | None — non-contact process | High — cutting tools dull quickly | Moderate — blades wear over time | High — nozzles and pumps wear from abrasive use |

| Material Waste | Minimal (thin kerf <0.2 mm) | Moderate | Low | Moderate to high (especially with abrasives) |

| Operating Cost | Low — mostly electricity and maintenance | Medium — bits and material waste | Low — inexpensive blades | High — abrasives, water, and power costs |

| Environmental Impact | Clean, no water waste | Minimal | Clean | Generates slurry and consumes large amounts of water |

| Software Compatibility | Compatible with most CAD/CAM and design files | Standard CNC software | Basic vector design software | Specialized CAD/CAM software |

| Cutting Thickness Range | Best up to ~15 mm (material-dependent) | Varies widely by bit and material | Best for soft, thin materials | Can cut very thick materials (>100 mm) |

| Ideal Applications | Signage, crafts, packaging, engraving, prototyping | Woodworking, furniture, 3D carving | Soft goods, packaging, leatherwork | Industrial metal, stone, and glass cutting |

Why Choose Us

Advanced Technology

Our laser cutting machines feature high-speed, precision cutting with the latest laser technology, ensuring smooth edges, minimal waste, and superior efficiency across various materials and thicknesses.

Reliable Quality

Each machine undergoes rigorous quality control and durability testing to ensure long-term stability, low maintenance, and consistent high performance, even under demanding industrial conditions.

Comprehensive Support

We provide full technical support, including installation guidance, operator training, and after-sales service, ensuring smooth machine operation and minimal downtime for your business.

Cost-Effective Solutions

Our machines offer high performance at competitive prices, with customizable options to fit different production needs, helping businesses maximize their investment without compromising on quality.

Related Resources

Understanding The Odors Associated With Laser Cutting

This article provides a comprehensive guide to laser cutting odors, explaining the causes of odors, material-specific odors, health risks, and practical strategies for effectively controlling odors and ensuring safer operation.

What Safety Measures Should Be Taken When Operating Laser Cutting Machines

This article teaches the basic safety measures for operating a laser cutting machine, including hazard awareness, engineering controls, PPE, fire prevention, ventilation, training, and emergency response drills.

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Frequently Asked Questions

What Is The Price Of 60W CO2 Laser Cutting Machines?

- Entry-level machines at the lower end of the spectrum (around $2,350–$3,500) are typically compact desktop models designed for small-scale users, craft studios, or educational settings. These units usually offer cutting areas between 400×600mm and 600×900mm and are equipped with standard components such as a glass laser tube, stepper motors, and manual focusing. Despite their affordability, they deliver impressive accuracy and can process wood, acrylic, leather, and paper efficiently. Their cost-effectiveness makes them popular among beginners and small businesses seeking reliable engraving and light cutting capabilities.

- Mid-range systems, priced between $3,500 and $5,500, provide larger workspaces, improved motion systems, and higher cutting speeds. Machines in this category often feature more durable mechanical structures, precision linear guides, and enhanced cooling systems for stable long-term operation. Many models come with Ruida or TopWisdom control systems, enabling smooth connectivity with software like LightBurn and CorelDRAW. These machines suit users who handle moderate production volumes or require consistent precision in signage, decoration, or prototyping.

- High-end 60W CO2 laser cutting machines, costing between $6,000 and $8,150, are built for professional and industrial applications. They often include servo motors, motorized Z-axis tables, auto-focusing lenses, and dual-head configurations for high productivity. The build quality is superior, with aluminum or steel honeycomb worktables and advanced smoke extraction and air-assist systems. Some models support rotary attachments, expanding their usability to cylindrical objects like bottles and pipes. These machines are ideal for continuous operation in workshops producing furniture components, large-format displays, or detailed architectural models.

What Are The Working Areas Of 60W CO2 Laser Cutting Machines?

- Small-format machines (600×400mm and 900×600mm) are ideal for hobbyists, studios, and small businesses that focus on detailed engraving or small parts cutting. They excel in producing signage, personalized gifts, and craft products. These compact machines fit easily on a workbench, consume less power, and require minimal ventilation setups. Despite their small size, they deliver high precision and can cut or engrave wood, acrylic, leather, or paper with professional-quality results.

- Medium-format models (1300×900mm and 1600×1000mm) strike a balance between versatility and footprint. These are the most popular configurations for small manufacturing workshops and sign-making businesses. The larger bed allows users to process bigger panels or multiple smaller pieces in one pass, improving productivity. Many machines at this size feature motorized lifting tables, automatic focusing, and support for rotary attachments, expanding the range of materials and shapes they can handle.

- Large-format CO2 laser cutting machines (1800×1000mm, 1300×1800mm, and 1300×2500mm) are designed for users who frequently work with full sheets of acrylic, MDF, or fabric. The extended work area allows seamless cutting without repositioning the material, ensuring high accuracy over large designs. These machines often come with dual-head options, conveyor worktables for roll materials, and advanced exhaust systems to maintain cutting quality and operator safety.

- At the industrial end, ultra-large work areas such as 1600×2600mm and 1500×3000mm accommodate oversized materials used in furniture making, exhibition design, and architectural model fabrication. They provide continuous operation capabilities for mass production and can integrate with automation systems like feeding conveyors or CCD cameras for precise contour recognition.

What Factors Affect The Price Of 60W CO2 Laser Cutting Machines?

- Machine Size and Work Area: CO2 laser cutting machines come in various working areas, such as 600×400mm, 1300×900mm, or even 1500×3000mm. Larger worktables require stronger frames, longer guide rails, and more powerful motion systems, which increase material and manufacturing costs. Compact models are affordable and ideal for small-scale production, while industrial-sized units are more expensive due to their enhanced stability and production efficiency.

- Mechanical and Optical Quality: The build quality of the frame, motion system, and optics plays a crucial role. Machines using precision linear guide rails, servo motors, and reinforced steel frames cost more than those with simple belt drives or aluminum structures. Similarly, high-end optics—like imported focusing lenses and gold-coated mirrors—improve beam transmission and edge smoothness but add to the overall price.

- Laser Tube Type and Lifespan: The brand, power stability, and longevity of the laser tube significantly impact cost. Premium tubes such as RECI or EFR provide longer lifespans (2,000–4,000 hours) and better cutting consistency compared to lower-cost generic tubes. Water-cooling systems and power supplies also influence the total investment.

- Control System and Software Compatibility: Advanced control systems—like Ruida or TopWisdom—allow precise layer management, auto-focusing, and integration with software such as LightBurn or CorelDRAW. These controllers enhance productivity and reliability but come at a higher cost than basic, entry-level boards.

- Automation and Additional Features: Features like motorized Z-axis tables, red-dot pointers, rotary attachments, air-assist systems, and smoke extractors enhance user convenience and expand the range of applications. Machines equipped with dual laser heads or camera-assisted positioning systems for contour cutting are priced significantly higher due to added precision and automation.

- Brand Reputation and After-Sales Service: Established manufacturers that offer technical training, warranty coverage, and spare parts availability typically price their machines higher. However, the reliability, support, and reduced downtime justify the premium.

What Is The Cutting Precision Of 60W CO2 Laser Cutting Machines?

- Machine Structure and Motion System: Precision largely depends on the mechanical stability of the laser cutting machine. Machines with rigid steel frames, linear guide rails, and stepper or servo motors ensure smooth, vibration-free movement of the laser head. These features minimize mechanical errors and maintain consistent alignment, especially when cutting thin or intricate shapes. Higher-end models using ball screws or servo-driven systems achieve tighter tolerances, offering superior accuracy for professional-grade applications.

- Optical and Laser Tube Quality: The beam quality and focus stability of the CO2 laser tube play a vital role in achieving fine precision. Premium laser tubes produce a stable beam with a consistent spot size, allowing for crisp, narrow cuts. Additionally, high-quality focusing lenses and mirrors ensure optimal energy delivery to the workpiece. Proper lens cleaning and alignment are essential to prevent beam divergence, which can reduce edge quality.

- Control System and Calibration: Advanced controllers such as Ruida or TopWisdom enhance precision through accurate motion coordination and smooth path execution. These systems allow micro-adjustments in cutting speed, acceleration, and laser power to match different materials. When paired with design software like LightBurn, users can optimize cutting layers and power settings for consistent, repeatable results.

- Material and Processing Factors: Material thickness, density, and surface properties also affect precision. Softer materials like foam and fabric may have wider kerf widths, while harder materials such as acrylic or MDF cut with sharper, cleaner edges. Using air assist systems helps remove debris from the cutting path, maintaining clarity and preventing charring that could distort fine details.

What Are The Disadvantages Of 60W CO2 Laser Cutting Machines?

- Limited Metal Cutting Capability: A major disadvantage of 60W CO2 laser cutting machines is their inability to efficiently cut metals. The infrared wavelength (10.6 μm) of CO2 lasers is poorly absorbed by reflective surfaces such as aluminum, brass, or copper. While coated or painted thin metals may be processed, the results are inconsistent and can damage the laser optics due to reflected energy. For metalworking applications, a fiber laser is a much better choice.

- Restricted Cutting Thickness: 60W lasers offer limited penetration power. It performs well on thin to medium-thickness materials—such as 10–12 mm acrylic or 6–8 mm wood—but struggles with thicker sheets. Attempting to cut beyond its capacity results in burn marks, tapered edges, or incomplete cuts. Users working with thicker materials often need higher-power lasers (300W–600W) for cleaner results.

- Maintenance and Consumable Costs: Although affordable initially, CO2 lasers require regular maintenance. The glass laser tube has a finite lifespan (1,500–3,000 hours) and needs replacement once its output power declines. Optical lenses and mirrors must also be kept clean and aligned. Water-cooling systems require continuous monitoring to prevent overheating, adding to operational complexity and cost.

- Fume and Gas Emission Risks: Cutting or engraving certain materials—such as plastics, synthetic leather, or rubber—produces toxic fumes and particulates. Without a proper ventilation or filtration system, these emissions can be harmful to operators and the environment. Additionally, materials like PVC should never be processed, as they release corrosive chlorine gas that can damage the machine and pose serious health hazards.

- Slower Cutting Speed Compared to High-Power Systems: While precise, 60W CO2 lasers have lower cutting speeds on dense materials. For industrial-scale production requiring high throughput, they may not meet efficiency demands.

How To Choose 60W CO2 Laser Cutting Machines?

- Define Application Requirements: Before selecting a model, clearly identify what materials and thicknesses you intend to cut or engrave. 60W lasers are best for non-metallic materials like wood, acrylic, leather, fabric, rubber, and paper. For frequent cutting of thicker materials, consider a larger working area and high-quality optics for consistent energy output. Understanding your production volume—whether for small crafts or industrial prototyping—will help determine whether you need a compact desktop machine or a large-format system.

- Evaluate Working Area and Machine Size: CO2 laser cutting machines come in various bed sizes, such as 600×400mm, 900×600mm, and 1300×900mm. Smaller models are ideal for limited workspace and light production, while larger tables allow you to cut full sheets and improve efficiency. A bigger working area also supports adding a rotary attachment for cylindrical engraving, enhancing versatility.

- Check Motion and Control Systems: Precision depends on the machine’s mechanical structure and controller. Look for systems with linear guide rails, Ruida or TopWisdom control boards, and stepper or servo motors for smooth, stable movement. These ensure accurate cutting with minimal vibration. Compatibility with LightBurn or CorelDRAW software is another advantage for easy design integration.

- Consider Laser Tube Quality and Cooling: The laser tube defines power stability and lifespan. Trusted brands like RECI or EFR provide consistent performance and longer service life. Pair the tube with an efficient water chiller (CW-3000 or CW-5200) to maintain temperature control and prevent overheating during extended operation.

- Assess Additional Features: Useful enhancements include auto-focus, air assist, exhaust systems, red-dot positioning, and motorized Z-tables. These improve ease of use and cutting quality. Machines with robust steel frames and safety enclosures offer better durability and operator protection.

- Review Brand Support and Warranty: Choose manufacturers that provide comprehensive after-sales service, technical training, and spare parts availability. Reliable support reduces downtime and ensures long-term cost efficiency.

Is It Safe To Use 60W CO2 Laser Cutting Machines?

- Laser Beam Safety: CO2 lasers emit an invisible infrared beam (10.6 μm wavelength) capable of burning or igniting materials on contact. Direct or reflected exposure can cause severe eye or skin injuries. To minimize risks, most 60W machines are enclosed within a protective housing or fitted with a transparent laser safety cover made from infrared-blocking acrylic. Users should never operate the machine with covers open and should wear laser safety goggles if maintenance or calibration requires open access to the laser path.

- Fume and Ventilation Control: Cutting or engraving organic materials such as wood, leather, or acrylic releases smoke and volatile gases. Some materials, including PVC or chlorinated rubber, emit toxic chlorine compounds and should never be processed. A built-in exhaust fan or external filtration system is necessary to remove fumes, prevent respiratory irritation, and maintain indoor air quality. Proper ventilation also protects optics and electronics from residue buildup.

- Fire and Heat Hazards: Because the laser beam vaporizes material through heat, there is always a risk of ignition, especially with paper, fabric, or foam. Operators must never leave the machine unattended during operation. An air assist system, which directs compressed air to the cutting area, helps reduce flare-ups and improve cut quality by clearing debris and dissipating heat. Keeping a fire extinguisher nearby is also recommended.

- Electrical and Cooling System Safety: CO2 lasers require high-voltage power supplies and water-cooling systems to prevent tube overheating. Regularly check water levels, flow rate, and electrical insulation to avoid malfunctions. Always turn off and unplug the machine before performing maintenance.

- User Training and Supervision: Safe operation depends on user awareness. Beginners should receive basic training on material safety, parameter settings, and emergency shutdown procedures.

What Problems Might Occur When Using 60W CO2 Laser Cutting Machines?

- Inconsistent Cutting Quality: One of the most common problems is uneven or incomplete cuts, often caused by incorrect laser focus, dirty optics, or worn-out lenses and mirrors. If the beam alignment is off, the laser won’t deliver uniform energy to the work surface, resulting in jagged or partially cut edges. Regular optical cleaning, mirror calibration, and focus adjustment are essential to maintain precise beam performance.

- Burn Marks and Charring: Since CO2 lasers generate heat to vaporize material, burning or dark edges can occur, especially when cutting wood, leather, or fabric. Using excessive power, low cutting speeds, or insufficient air assist can intensify this effect. Properly adjusting power and speed parameters, along with ensuring adequate airflow, helps achieve clean, polished edges without discoloration.

- Smoke and Fume Build-Up: Improper ventilation is another frequent issue. Without an effective exhaust system, smoke and debris can accumulate inside the laser chamber, reducing visibility and contaminating optical components. Over time, this residue can affect beam focus and reduce laser output power. Operators should always ensure that ventilation ducts and filters are clear and functioning efficiently.

- Laser Tube Power Decline: The glass laser tube in 60W CO2 laser cutting machines gradually loses efficiency after 1,500–3,000 operating hours. As output power decreases, cutting depth and speed are reduced. A weakening beam often signals it’s time to replace the laser tube or check the power supply and cooling system for malfunctions.

- Cooling and Water Circulation Failures: If the water-cooling system fails or the temperature rises too high, the laser tube can overheat and crack. Users must monitor coolant temperature, water flow, and chiller performance during operation. Using distilled water and stable flow systems minimizes this risk.

- Software or Connection Errors: Occasional issues such as communication failures between the control board and design software (e.g., LightBurn or RDWorks) can interrupt jobs. Ensuring updated firmware and stable USB or network connections helps avoid data loss.