Product Introduction

CO2 Laser Cutting Capabilities

| Material Type | 60W | 80W | 90W | 100W | 130W | 150W | 180W | 220W | 260W | 300W | 500W | 600W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Acrylic | 0-8mm | 0-10mm | 0-12mm | 0-15mm | 0-18mm | 0-20mm | 0-22mm | 0-25mm | 0-28mm | 0-30mm | 0-35mm | 0-40mm |

| Plywood | 0-6mm | 0-8mm | 0-9mm | 0-10mm | 0-12mm | 0-15mm | 0-15mm | 0-18mm | 0-20mm | 0-22mm | 0-25mm | 0-28mm |

| MDF | 0-5mm | 0-6mm | 0-8mm | 0-9mm | 0-12mm | 0-15mm | 0-15mm | 0-18mm | 0-20mm | 0-22mm | 0-25mm | 0-25mm |

| Solid Wood | 0-5mm | 0-6mm | 0-8mm | 0-10mm | 0-12mm | 0-15mm | 0-15mm | 0-18mm | 0-20mm | 0-22mm | 0-25mm | 0-25mm |

| Bamboo Board | 0-5mm | 0-6mm | 0-8mm | 0-10mm | 0-12mm | 0-15mm | 0-15mm | 0-18mm | 0-20mm | 0-22mm | 0-25mm | 0-25mm |

| Leather | 0-4mm | 0-5mm | 0-5mm | 0-6mm | 0-6mm | 0-8mm | 0-8mm | 0-8mm | 0-10mm | 0-10mm | 0-12mm | 0-12mm |

| Textile | Any Cutting | Any Cutting | Any Cutting | Any Cutting | Any Cutting | Any Cutting | Any Cutting | Any Cutting | Any Cutting | Any Cutting | Any Cutting | Any Cutting |

| Rubber | 0-3mm | 0-4mm | 0-5mm | 0-5mm | 0-6mm | 0-6mm | 0-8mm | 0-8mm | 0-8mm | 0-10mm | 0-10mm | 0-10mm |

| EVA | 0-5mm | 0-6mm | 0-8mm | 0-10mm | 0-12mm | 0-15mm | 0-15mm | 0-18mm | 0-20mm | 0-25mm | 0-30mm | 0-30mm |

| Cardboard | 0-3mm | 0-4mm | 0-4mm | 0-5mm | 0-6mm | 0-6mm | 0-8mm | 0-8mm | 0-8mm | 0-10mm | 0-10mm | 0-10mm |

| Cork Sheet | 0-3mm | 0-4mm | 0-5mm | 0-5mm | 0-6mm | 0-6mm | 0-8mm | 0-8mm | 0-8mm | 0-10mm | 0-10mm | 0-10mm |

| ABS | 0-3mm | 0-4mm | 0-5mm | 0-6mm | 0-8mm | 0-8mm | 0-10mm | 0-10mm | 0-12mm | 0-12mm | 0-15mm | 0-15mm |

| Delrin | 0-3mm | 0-4mm | 0-5mm | 0-6mm | 0-8mm | 0-8mm | 0-10mm | 0-10mm | 0-12mm | 0-12mm | 0-15mm | 0-15mm |

| Foam Board | 0-5mm | 0-6mm | 0-8mm | 0-10mm | 0-12mm | 0-15mm | 0-18mm | 0-20mm | 0-25mm | 0-25mm | 0-30mm | 0-30mm |

| PCB | 0-1mm | 0-1.5mm | 0-2mm | 0-2mm | 0-3mm | 0-3mm | 0-3mm | 0-4mm | 0-4mm | 0-5mm | 0-5mm | 0-5mm |

| Laminates | 0-3mm | 0-4mm | 0-5mm | 0-6mm | 0-8mm | 0-8mm | 0-10mm | 0-10mm | 0-12mm | 0-12mm | 0-15mm | 0-15mm |

| Stone | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only |

| Ceramic | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only | Engraving Only |

Compatible Materials

- Rubber

- Delrin

- ABS Plastic

- Polystyrene

- Polycarbonate

- PETG

- EVA Foam

- Neoprene

- Mylar

- Nylon

- Canvas

- Suede

- Fleece

- Cardstock

- Veneer

- Latex

- Foam Board

- Pressboard

- Melamine

- Carbon Fiber

- Linoleum

- Birch Plywood

- Walnut Plywood

- Alder Wood

- Basswood

- Chipboard

- Hardboard

- Synthetic Felt

- Wool Fabric

- Polyurethane Foam

Application of 100W CO2 Laser Cutting Machines

Customer Testimonials

Comparison VS Other Cutting Technologies

| Comparison Item | CO2 Laser Cutting | CNC Routing | Knife Cutting | Waterjet Cutting |

|---|---|---|---|---|

| Cutting Principle | Uses a focused laser beam to vaporize material | Uses rotating cutting bits to remove material | Uses a sharp blade to slice through material | Uses a high-pressure jet of water (with or without abrasive) |

| Suitable Materials | Non-metals like wood, acrylic, leather, fabric, rubber | Wood, plastics, composites, soft metals | Soft materials like foam, leather, textiles, and paper | Almost all materials, including metal, stone, glass, and composites |

| Cutting Precision | Very high (±0.05 mm) | Moderate (±0.2 mm) | Moderate to high (±0.1 mm) | High (±0.1 mm) |

| Edge Quality | Smooth, sealed edges (especially on acrylic and wood) | May require sanding or finishing | Clean for soft materials | Smooth but can be slightly rough on thick cuts |

| Cutting Speed | Fast for thin to medium materials | Slower due to mechanical resistance | Fast on soft materials | Slower, especially for thick or hard materials |

| Maintenance | Low — no physical contact with material | Medium — bits wear out regularly | Low — blades replaced periodically | High — pumps, nozzles, and abrasive handling required |

| Noise Level | Quiet operation | Noisy (due to motor and bit contact) | Very quiet | Very loud (requires sound enclosure) |

| Heat Effect | Generates localized heat (may char some materials) | Minimal heat | No heat | No heat |

| Tool Wear | None — non-contact process | High — cutting tools dull quickly | Moderate — blades wear over time | High — nozzles and pumps wear from abrasive use |

| Material Waste | Minimal (thin kerf <0.2 mm) | Moderate | Low | Moderate to high (especially with abrasives) |

| Operating Cost | Low — mostly electricity and maintenance | Medium — bits and material waste | Low — inexpensive blades | High — abrasives, water, and power costs |

| Environmental Impact | Clean, no water waste | Minimal | Clean | Generates slurry and consumes large amounts of water |

| Software Compatibility | Compatible with most CAD/CAM and design files | Standard CNC software | Basic vector design software | Specialized CAD/CAM software |

| Cutting Thickness Range | Best up to ~15 mm (material-dependent) | Varies widely by bit and material | Best for soft, thin materials | Can cut very thick materials (>100 mm) |

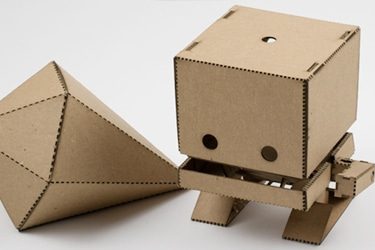

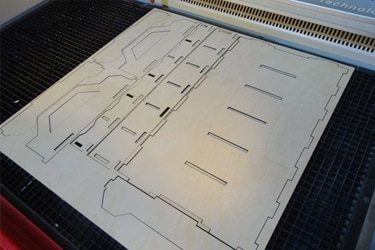

| Ideal Applications | Signage, crafts, packaging, engraving, prototyping | Woodworking, furniture, 3D carving | Soft goods, packaging, leatherwork | Industrial metal, stone, and glass cutting |

Why Choose Us

Advanced Technology

Our laser cutting machines feature high-speed, precision cutting with the latest laser technology, ensuring smooth edges, minimal waste, and superior efficiency across various materials and thicknesses.

Reliable Quality

Each machine undergoes rigorous quality control and durability testing to ensure long-term stability, low maintenance, and consistent high performance, even under demanding industrial conditions.

Comprehensive Support

We provide full technical support, including installation guidance, operator training, and after-sales service, ensuring smooth machine operation and minimal downtime for your business.

Cost-Effective Solutions

Our machines offer high performance at competitive prices, with customizable options to fit different production needs, helping businesses maximize their investment without compromising on quality.

Related Resources

Understanding The Odors Associated With Laser Cutting

This article provides a comprehensive guide to laser cutting odors, explaining the causes of odors, material-specific odors, health risks, and practical strategies for effectively controlling odors and ensuring safer operation.

What Safety Measures Should Be Taken When Operating Laser Cutting Machines

This article teaches the basic safety measures for operating a laser cutting machine, including hazard awareness, engineering controls, PPE, fire prevention, ventilation, training, and emergency response drills.

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Frequently Asked Questions

What Is The Price Of 100W CO2 Laser Cutting Machines?

- Entry-Level Models ($2,650–$3,800): Machines at the lower end of the price range are compact units suitable for small-scale production or hobbyist use. These models typically feature working areas between 600×400mm and 900×600mm, manual focusing, and basic motion systems. Despite their simplicity, they deliver precise cutting and engraving results on non-metallic materials like wood, acrylic, and leather. Their low cost and user-friendly operation make them perfect for small studios and startup businesses.

- Mid-Range Models ($3,800–$5,800): Mid-tier 100W CO2 laser cutting machines are designed for professional users seeking a balance between power and versatility. They usually offer larger bed sizes such as 1300×900mm or 1600×1000mm, motorized Z-axis tables, and Ruida or TopWisdom control systems for improved precision and automation. These machines handle thicker materials (up to 20 mm acrylic or 12 mm wood) while maintaining clean, polished edges. Many include air assist, red-dot pointers, and efficient water-cooling systems, ensuring consistent performance during long cutting sessions.

- High-End Models ($6,000–$8,450): At the upper end of the range are industrial-grade CO2 laser cutting machines designed for continuous, high-precision production. These models feature servo motor drives, reinforced steel frames, auto-focus systems, and dual laser heads to maximize throughput. Some are equipped with conveyor worktables or CCD camera positioning systems for contour cutting printed materials. The laser tubes often come from premium manufacturers like RECI or EFR, offering longer lifespans (3,000–5,000 hours) and stable power output. Such machines can efficiently cut large-format materials, including MDF, fabric, foam, and acrylic sheets, with exceptional consistency.

What Are The Working Areas Of 100W CO2 Laser Cutting Machines?

- Small-Format Machines (600×400mm, 900×600mm): Compact machines in this category are ideal for engraving, small crafts, and precision cutting tasks. They fit easily in workshops, classrooms, or small production studios and are perfect for processing wood, leather, paper, and thin acrylic sheets. Despite their smaller footprint, they maintain excellent precision and are well-suited for customized production, signage engraving, and prototype fabrication.

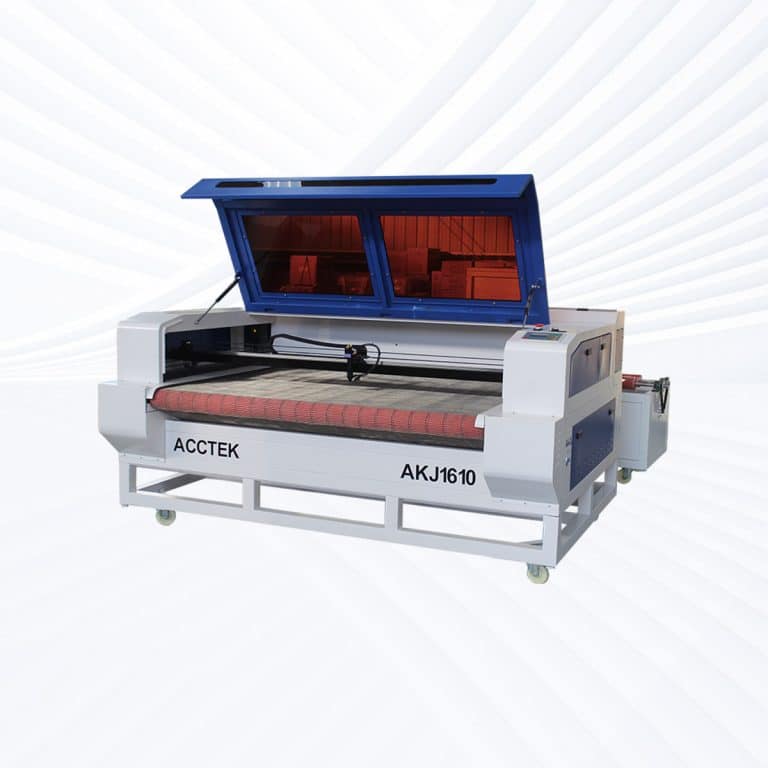

- Medium-Format Machines (1300×900mm, 1600×1000mm, 1800×1000mm): These models represent the most popular size range among professionals and small manufacturers. Their larger bed size allows cutting of standard sheet materials like 4×8-foot wood panels or large acrylic boards without repositioning, which greatly improves workflow and accuracy. Equipped with features such as motorized Z-axis tables, red-dot positioning, and autofocus, these machines deliver consistent, high-quality results for sign-making, architectural models, and furniture components.

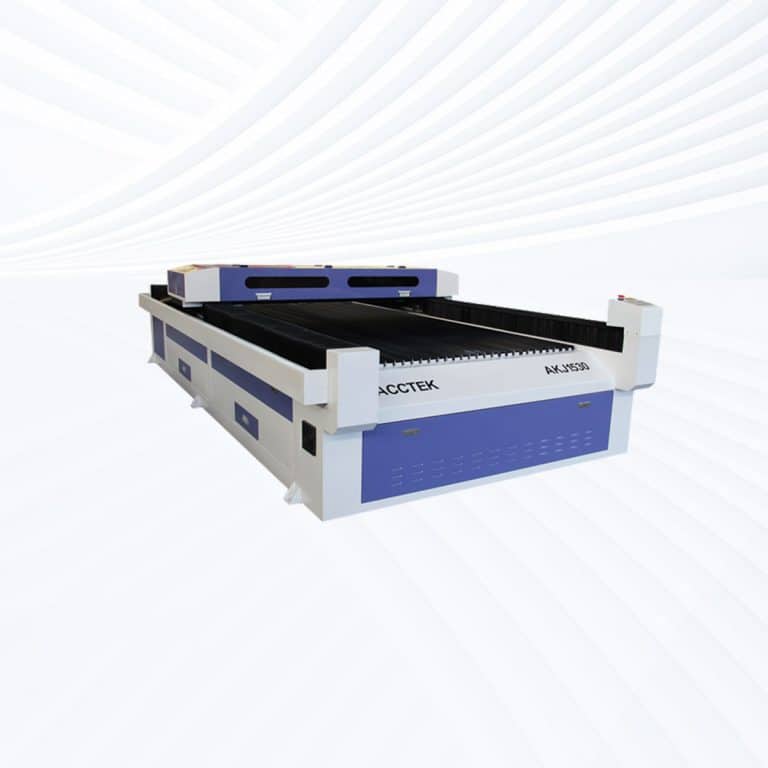

- Large-Format Machines (1300×1800mm, 1300×2500mm): Designed for high-volume and industrial applications, these machines can handle larger sheets of MDF, plywood, fabric, or plastic. The extended work area accommodates complex designs and multiple parts in one pass, maximizing productivity. Many include dual-head systems, conveyor feeding platforms, or roll-to-roll mechanisms, which enhance efficiency when processing continuous materials such as leather or textiles.

- Extra-Large Industrial Machines (1600×2600mm, 1500×3000mm): These large-format CO2 laser cutting systems are built for heavy-duty and large-scale production. Their vast working area allows seamless cutting of oversized materials used in furniture, signage, automotive interiors, and packaging industries. Reinforced frames, servo motor drives, and advanced air-assist systems ensure precision and speed across the entire surface.

How Clean Is The Cut Edge Of 100W CO2 Laser Cutting Machines?

- Wood and Wood-Based Products: When cutting plywood, MDF, or solid wood, 100W CO2 lasers produce sharp and well-defined edges with minimal burring. However, due to the higher heat intensity, darker edges or slight charring may occur on some wood types. Optimizing laser power and speed settings, combined with effective air assist and exhaust systems, can greatly reduce burn marks and preserve a natural-looking finish. Proper ventilation also helps prevent smoke staining on light-colored woods.

- Acrylic and Plastics: Acrylic (PMMA) responds extremely well to 100W CO2 lasers, producing crystal-clear, flame-polished edges without the need for secondary finishing. The focused laser beam melts the acrylic’s edge smoothly, creating a glossy surface ideal for displays, signs, and decorative panels. Other plastics, such as ABS or polyethylene, may also yield clean edges; however, care must be taken to manage heat buildup to avoid melting or warping.

- Paper and Cardboard: Thin materials such as paper, cardstock, or cardboard cut with precise, burn-free edges when the power is properly reduced. Excessive energy can cause ignition or edge darkening, so maintaining lower power and higher speed settings is crucial for maintaining cut cleanliness and accuracy.

- Leather and Fabrics: For natural leathers and textiles, the 100W CO2 laser provides smooth, sealed edges that prevent fraying. However, synthetic leathers or coated fabrics may produce less clean edges if they contain materials that react poorly to heat. Testing and airflow adjustments ensure consistent results.

- Foam and Rubber: Laser-safe foams and rubbers produce smooth, accurate edges, though some materials may emit residues if not ventilated properly. Continuous air assist helps maintain clarity and prevents edge discoloration.

Is It Safe To Use 100W CO2 Laser Cutting Machines?

- Laser Radiation Safety: 100W CO2 lasers emit an invisible infrared beam (10.6 µm wavelength), which can cause severe eye or skin injuries upon direct or reflected exposure. Fortunately, most modern machines are fully enclosed with interlocked covers, preventing the laser from operating when the lid is open. Operators should always wear certified laser safety goggles if alignment or maintenance exposes the beam path. Additionally, non-reflective materials should be used around the workspace to avoid accidental reflections.

- Fume and Ventilation Safety: Cutting materials such as wood, acrylic, or leather generates smoke and volatile organic compounds (VOCs). Some plastics, especially PVC, can emit toxic chlorine gas and should never be processed. Therefore, every 100W CO2 laser must be equipped with a powerful exhaust or filtration system to remove fumes and particulates from the cutting area. Proper ventilation not only protects the operator’s health but also keeps optical components clean and prevents smoke buildup that could degrade cutting quality.

- Fire Prevention and Thermal Hazards: The high intensity of a 100W laser can ignite flammable materials such as paper, foam, or fabric. To reduce fire risks, users should never leave the machine unattended during operation. A reliable air assist system helps blow away debris and prevent flames from forming at the cutting point. Keeping a CO2 or dry powder fire extinguisher within reach is recommended for emergencies.

- Electrical and Cooling Safety: Since 100W CO2 lasers rely on high-voltage power supplies and water cooling, users must ensure all connections are properly grounded and cooling water is clean and at an optimal temperature (18–25℃). Regular inspections prevent overheating or leaks that could damage components.

How To Choose 100W CO2 Laser Cutting Machines?

- Determine Application and Material Requirements: Start by identifying the materials you plan to cut or engrave—such as wood, acrylic, leather, fabric, or rubber—and their maximum thickness. A 100W laser easily handles 10–20 mm acrylic or 12–15 mm wood, making it ideal for signage, furniture parts, and packaging applications. If your work involves detailed engraving, look for a model with fine beam control and high-resolution capability.

- Choose an Appropriate Working Area: CO2 laser cutting machines are available in various bed sizes, including 900×600mm, 1300×900mm, and 1600×1000mm. Larger worktables accommodate bigger materials and improve efficiency by allowing multiple parts to be processed at once. However, if space is limited or projects are small-scale, a compact system will be more cost-effective and easier to maintain.

- Evaluate Laser Tube Quality and Cooling System: The laser tube is the core of the system. Choose reputable brands such as RECI or EFR for stable output and longer lifespan (3,000–5,000 hours). A water chiller (CW-5200 or equivalent) is essential to maintain the laser tube temperature between 18–25°C. Proper cooling ensures consistent power and prevents tube burnout during long operations.

- Check Control System and Software Compatibility: Look for advanced controllers such as Ruida or TopWisdom, which provide smoother motion control and support popular design software like LightBurn or CorelDRAW. Features like autofocus, motorized Z-axis tables, and red-dot positioning enhance accuracy and convenience.

- Prioritize Safety, Ventilation, and Support: Ensure the machine includes air assist, exhaust fans, and safety interlocks to manage fumes and fire risks. Reliable after-sales service, warranty coverage, and easy access to spare parts are also vital for long-term operation.

What Is The Lifespan Of 100W CO2 Laser Cutting Machines?

- Laser Tube Lifespan: The CO2 laser tube is the most critical and consumable component of the system. A high-quality tube, such as those from RECI, EFR, or Yongli, typically lasts between 3,000 and 5,000 working hours under proper conditions. Continuous high-power operation, insufficient cooling, or poor water quality can shorten its life. To maximize durability, the cooling water temperature should remain between 18℃ and 25℃, and only distilled water should be used to prevent scale buildup or corrosion. Overheating and thermal shock are the most common causes of early tube failure.

- Optical System (Lenses and Mirrors): The focusing lens and reflection mirrors generally last for several years if cleaned regularly and protected from dust and smoke. Poor air filtration or improper cleaning can lead to optical degradation, reducing cutting power and edge quality. Using non-abrasive cleaning methods and maintaining a clean, dust-free environment ensures stable optical transmission and prevents costly replacements.

- Mechanical and Electrical Components: The motion system (rails, belts, bearings, and motors) can last 5–10 years or longer with periodic lubrication and calibration. High-end models with linear guide rails and servo motors tend to have greater longevity and smoother performance than entry-level systems. The power supply, control board, and water chiller also have multi-year lifespans if used in stable temperature and voltage conditions. Installing a voltage regulator or UPS helps prevent damage from power fluctuations.

- Machine Frame and Structure: The machine’s steel frame and housing are built to last over a decade, provided they are kept clean, level, and free of rust.

How To Maintain 100W CO2 Laser Cutting Machines?

- Laser Tube and Cooling System Maintenance: The CO2 laser tube is the heart of the machine and must be kept cool to prevent overheating. Always ensure the water-cooling system (chiller or pump) functions properly, maintaining the water temperature between 18℃ and 25℃. Use only distilled or deionized water to avoid scale buildup inside the tube. Regularly check for air bubbles or leaks in the cooling lines, as poor circulation can reduce laser power or shorten the tube’s lifespan. Clean the water tank and replace the coolant every few weeks.

- Optical System (Lenses and Mirrors): The mirrors and focusing lens should be inspected and cleaned frequently, as dust, smoke, or residue can obstruct the beam and lower cutting power. Use lint-free wipes and optical cleaner or isopropyl alcohol to gently remove contaminants. Never touch the optics with your bare hands. Misaligned mirrors should be recalibrated using the laser’s alignment procedure to maintain consistent beam focus and cutting precision.

- Air Assist and Exhaust Systems: A functioning air assist system prevents flare-ups and keeps debris away from the laser head. Check air nozzles and hoses for clogs and ensure steady airflow. The exhaust fan and filters must be cleaned regularly to maintain proper ventilation and remove harmful fumes generated during cutting. Good airflow also protects optical components from smoke buildup.

- Mechanical Components: Keep the guide rails, belts, and bearings clean and lubricated to ensure smooth movement. Inspect for loosened screws, worn belts, or misaligned parts. Regular calibration of the Z-axis and gantry system maintains accurate focusing and alignment across the worktable.

- Electrical and Software Maintenance: Inspect power cables, connectors, and grounding wires for wear. Use a voltage stabilizer to protect electronics from power fluctuations. Periodically back up software settings and update firmware to ensure compatibility with control systems like Ruida or TopWisdom.

What Training Is Required To Operate 100W CO2 Laser Cutting Machines?

- Basic Machine Operation Training: Operators must first learn the fundamentals of machine setup and operation. This includes understanding the laser control panel, power adjustment, focusing procedures, and bed height calibration. Training covers how to properly load materials, adjust speed and power settings, and interpret cutting parameters for different substrates. Hands-on instruction helps users recognize how power intensity and speed affect cut depth and edge quality on materials like wood, acrylic, and leather.

- Software and Design Skills: Proficiency in laser design software is essential for precise cutting and engraving. Most CO2 lasers use control systems like Ruida or TopWisdom, compatible with programs such as LightBurn, AutoCAD, or CorelDRAW. Operators should learn how to import vector designs, adjust layers for cutting or engraving, and optimize file settings for smooth workflow integration. Training should also include using software features like nesting (for material efficiency) and path optimization to reduce cutting time.

- Maintenance and Calibration Training: Routine maintenance is vital for long-term performance. Operators must understand how to clean and align mirrors, inspect lenses, manage water cooling, and maintain air assist and exhaust systems. Basic troubleshooting training helps users identify issues like beam misalignment, inconsistent power output, or poor cooling efficiency before they cause major damage.

- Safety and Emergency Procedures: Laser safety is a key part of operator training. Trainees should understand laser classification, PPE requirements, ventilation system use, and emergency response in case of fire or overheating. Awareness of prohibited materials (e.g., PVC, chlorinated rubbers) is critical to prevent the release of toxic fumes.

- Practical and Certification Courses: For industrial environments, formal certification courses or manufacturer-led workshops provide structured instruction and safety accreditation.