How Do CNC Routers Work

This article explains the working principle of CNC routers, from the motion system and cutting tools to the software workflow, materials, precision, and actual machining principles.

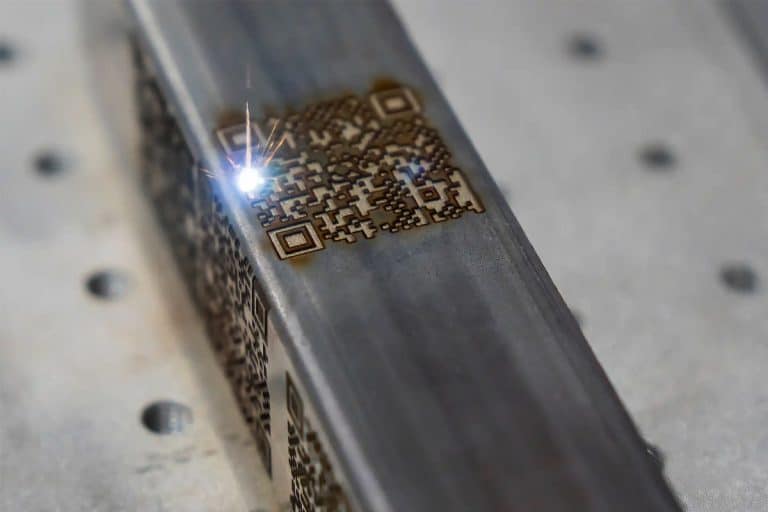

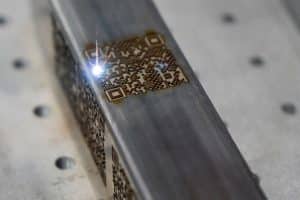

What Types of Laser Marking Machines Are There

This article explains the main types of laser marking machines, covering laser sources, marking methods, materials, applications, and how to choose the right system for production needs.

How To Select Laser Welding Power

This article teaches you how to select laser welding power and provides clear guidance on materials, thickness, welding modes, beam settings, defects, testing methods, and process optimization to achieve stable, high-quality welds.

Will Laser Cleaning Damage The Substrate

This article explains whether laser cleaning damages substrates, examining damage mechanisms, material risks, process control, and verification methods for safe, effective laser cleaning.

What Safety Measures Should Be Taken When Operating Laser Cutting Machines

This article teaches the basic safety measures for operating a laser cutting machine, including hazard awareness, engineering controls, PPE, fire prevention, ventilation, training, and emergency response drills.

Does Oscillating Knife Cutting Cause Material Deformation

This article explores the potential for material deformation during oscillating knife cutting, examining factors such as cutting parameters, material properties, and industry-specific applications.

How To Maintain CNC Routers

This article provides a comprehensive guide on how to maintain CNC routers, covering essential tasks, troubleshooting tips, upgrades, and best practices to ensure optimal performance and longevity.

What Safety Precautions Are Required For Laser Marking

This article outlines essential safety precautions required for laser marking, including equipment safety, operator training, emergency protocols, and routine maintenance to ensure safe and efficient operations.

Laser Welding VS Arc Welding

This article explores the key differences between laser welding and arc welding, comparing their processes, advantages, limitations, and ideal applications across various industries.

Comprehensive Guides to Choosing the Right Laser Cleaning Parameters

This comprehensive guide explores the key factors in choosing the right laser cleaning parameters, including material types, contamination levels, and practical considerations for optimal results.

How Do CNC Routers Work

This article explains the working principle of CNC routers, from the motion system and cutting tools to the software workflow, materials, precision, and actual machining principles.

What Types of Laser Marking Machines Are There

This article explains the main types of laser marking machines, covering laser sources, marking methods, materials, applications, and how to choose the right system for production needs.

How To Select Laser Welding Power

This article teaches you how to select laser welding power and provides clear guidance on materials, thickness, welding modes, beam settings, defects, testing methods, and process optimization to achieve stable, high-quality welds.

Will Laser Cleaning Damage The Substrate

This article explains whether laser cleaning damages substrates, examining damage mechanisms, material risks, process control, and verification methods for safe, effective laser cleaning.

What Safety Measures Should Be Taken When Operating Laser Cutting Machines

This article teaches the basic safety measures for operating a laser cutting machine, including hazard awareness, engineering controls, PPE, fire prevention, ventilation, training, and emergency response drills.

Does Oscillating Knife Cutting Cause Material Deformation

This article explores the potential for material deformation during oscillating knife cutting, examining factors such as cutting parameters, material properties, and industry-specific applications.

How To Maintain CNC Routers

This article provides a comprehensive guide on how to maintain CNC routers, covering essential tasks, troubleshooting tips, upgrades, and best practices to ensure optimal performance and longevity.

What Safety Precautions Are Required For Laser Marking

This article outlines essential safety precautions required for laser marking, including equipment safety, operator training, emergency protocols, and routine maintenance to ensure safe and efficient operations.

Laser Welding VS Arc Welding

This article explores the key differences between laser welding and arc welding, comparing their processes, advantages, limitations, and ideal applications across various industries.

Comprehensive Guides to Choosing the Right Laser Cleaning Parameters

This comprehensive guide explores the key factors in choosing the right laser cleaning parameters, including material types, contamination levels, and practical considerations for optimal results.