How Do I Choose Laser Cutting Machine Manufacturers

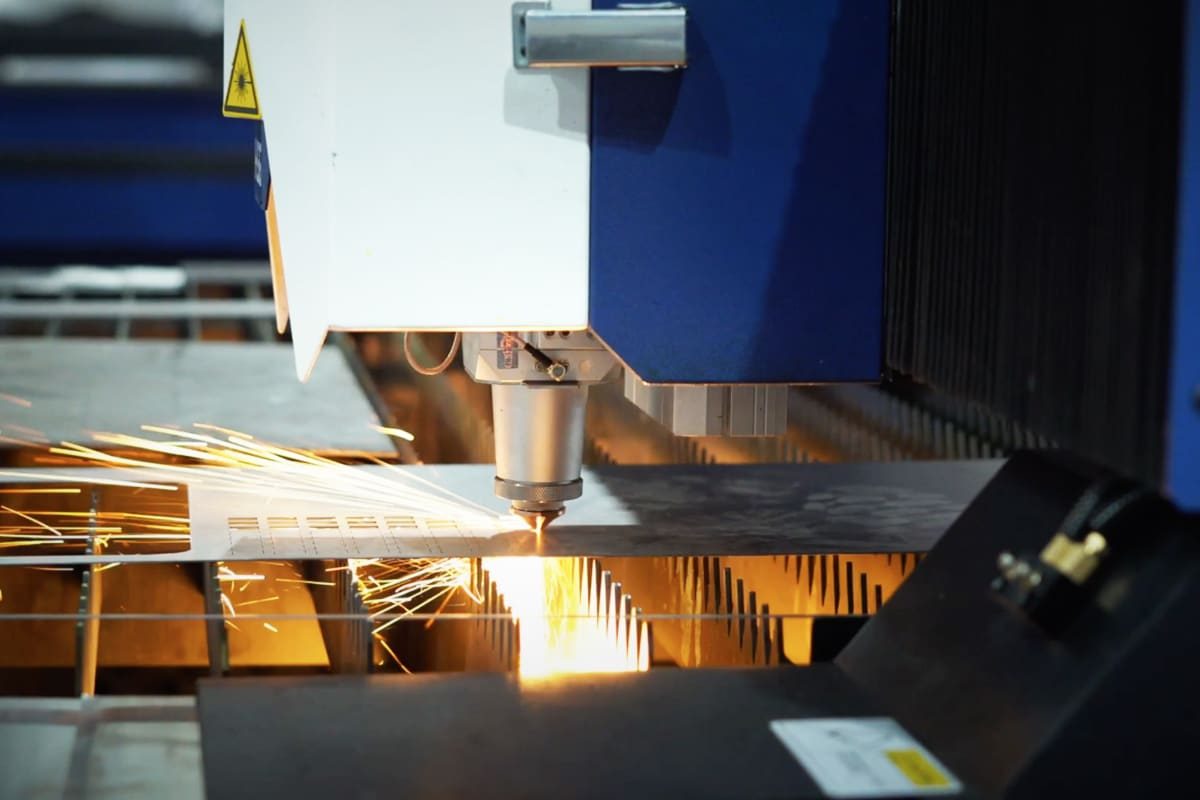

Choosing the right laser cutting machine manufacturer is a decision that goes far beyond comparing prices or scanning product catalogs. Laser cutting machines are a major investment—one that can define the efficiency, quality, and long-term success of your operations. Whether you run a small fabrication workshop or manage a large-scale production facility, the reliability of your machine and the support behind it directly impact your bottom line. With so many manufacturers on the market, from global industry leaders to smaller regional suppliers, the challenge lies in knowing which one will best meet your needs.

It’s not just about the machine itself. Factors such as after-sales service, technical expertise, spare parts availability, training, and the manufacturer’s track record all play a crucial role. The right partner should understand your industry, offer tailored solutions, and stand behind their technology with consistent support. On the other hand, choosing poorly could mean costly downtime, limited support, and machines that fail to deliver the precision and durability you require.

This article will guide you through the key criteria to consider when selecting laser cutting machine manufacturers so you can make a confident, informed choice.

Table of Contents

Start With Partner Fit, Not Product Specs

When most people start shopping for laser cutting machines, their first instinct is to compare specifications—power ratings, cutting speeds, table sizes, and software compatibility. While these details matter, they should not be the foundation of your decision. Machines can look similar on paper, but what truly sets manufacturers apart is the kind of partnership they offer.

Laser cutting machines are not a one-time purchase—it’s the start of a long-term relationship with the company behind it. You need a partner that understands your industry, responds quickly when problems arise, and offers support that grows with your business. A manufacturer with a solid reputation for training, service, and adaptability will save you far more time and money in the long run than one that simply delivers a machine with high-end specs.

Think about questions such as:

- Does the manufacturer provide reliable after-sales service and fast technical support?

- How accessible are spare parts and consumables?

- Do they invest in R&D and keep pace with evolving technology?

- Can they tailor solutions to your specific production needs?

In short, choosing the right manufacturer is less about the product and more about the partnership. Specs can tell you what a machine can do, but the manufacturer determines how well it will keep doing it years down the line. Prioritizing partner fit ensures you get not just a machine, but a dependable ally in your production process.

Understand Vendor Types

Not all companies that sell laser cutting machines are the same. Before comparing features or negotiating prices, it’s important to understand the type of vendor you’re dealing with. Each category—true OEMs, assemblers/branders, and distributors/resellers/integrators—comes with its own advantages, limitations, and implications for long-term ownership. Knowing the differences will help you set realistic expectations and choose a supplier whose model aligns with your business needs.

True OEMs (Original Equipment Manufacturers)

These are companies that design, engineer, and build machines from the ground up. They typically invest heavily in R&D, control the quality of components, and continuously refine their technology. OEMs usually offer the strongest after-sales infrastructure, including spare parts, upgrades, and training programs. While their machines may come at a premium price, buyers benefit from cutting-edge technology and reliable long-term support. If your business demands maximum precision, scalability, and future-proofing, OEMs are often the best fit.

Assemblers/Branders

Assemblers or branders source components—sometimes entire subsystems—from multiple suppliers and put them together under their own label. Their machines may look similar to OEM equipment, but the depth of engineering support can vary. Some branders focus on cost efficiency, while others emphasize customization. Support and spare parts availability may not be as consistent as with OEMs, and technology innovation depends on their suppliers. That said, they can be a good middle-ground option if you want a balance between affordability and performance.

Distributors/Resellers/Integrators

These vendors don’t manufacture equipment themselves. Instead, they represent one or more machine makers and handle sales, installation, and sometimes service. The upside is accessibility—they’re often local, easy to reach, and able to provide quick service. The downside is limited control over product design, long-term upgrades, or parts availability since they depend on the original manufacturer. However, if your priority is local service and immediate response, working with a reliable distributor or integrator can be a practical choice.

Each vendor type comes with trade-offs. OEMs offer unmatched technology and long-term assurance, branders provide flexible and cost-sensitive options, and distributors deliver local service and accessibility. The key is not to assume all vendors are equal—evaluate the type of company you’re dealing with and weigh it against your production priorities, budget, and growth plans.

Field Service Footprint

Laser cutting machines are only as reliable as the service network that stands behind them. Downtime is expensive, and when issues arise, the speed and quality of support directly affect your productivity. That’s why evaluating a manufacturer’s field service footprint is just as critical as assessing the machine itself. A strong footprint ensures you’re never left stranded when you need help most.

Coverage Map with Named Techs

Don’t settle for vague promises of “nationwide” or “global” coverage. Ask for a detailed service map and confirmation of which technicians cover your region. Named, dedicated techs mean accountability—you know who will show up, and they know your equipment history.

Response Commitments

Reputable manufacturers offer service-level agreements (SLAs) with clear response time guarantees. Whether it’s a four-hour callback or a 24-hour onsite visit, written commitments protect you from indefinite delays.

Historical Metrics

Look beyond promises. Ask for data on average response times, first-time fix rates, and customer satisfaction scores. A track record of meeting service commitments is the best predictor of future reliability.

Service Parts Depots

Even the best technicians can’t fix machines without parts. Confirm the location of regional depots and the manufacturer’s stocking strategy. A nearby depot significantly shortens repair times compared to waiting for international shipments.

Escalation Ladder

Complex problems sometimes require higher-level intervention. A strong service organization should have a clear escalation ladder—from field techs to regional managers to engineering specialists—so your issue doesn’t get stuck in limbo.

Remote Diagnostics

Modern laser cutting machines often come with IoT-based monitoring and remote diagnostic tools. This allows manufacturers to troubleshoot problems, push software fixes, or pre-diagnose issues before sending a tech, saving you time and money.

Simple Field Test

A practical way to verify service claims is to test them. Place a service call—before you buy—and see how quickly they respond, how knowledgeable the support staff is, and how smoothly the process runs.

A robust field service footprint is the safety net that protects your investment. Look for transparent coverage, measurable commitments, and infrastructure that supports fast, effective fixes. Manufacturers who can demonstrate depth in service—through tech availability, spare parts access, and escalation systems—give you peace of mind that your machine will keep running when you need it most.

Spare Parts Reality

Laser cutting machines are a precision tool, but like any machine, they rely on consumables and components that eventually wear out. When those parts fail, your production stops—and every hour of downtime costs money. That’s why understanding the spare parts reality of your manufacturer is just as important as reviewing their technical specs. A strong parts strategy means fewer surprises, faster recovery, and lower long-term costs.

Stocking Policy

Ask how the manufacturer manages spare parts inventory. Do they keep critical items in regional depots, or will replacements need to ship from overseas? The difference could mean same-day service versus weeks of waiting. Ideally, the vendor should provide a recommended “critical spares kit” for you to keep on hand, reducing dependence on their supply chain in emergencies.

Lead-Time Transparency

Reliable manufacturers don’t just promise availability—they publish lead times and stick to them. You should know exactly how long it takes to get replacement optics, drive motors, or controllers. Vague answers here are a red flag.

Price Stability

Some vendors lure customers with affordable machine prices but mark up spare parts aggressively. Evaluate whether the manufacturer maintains consistent, fair pricing for parts or if they treat them as a profit center. Long-term ownership costs hinge heavily on parts pricing.

Loaners

For high-value items like control boards or laser sources, ask if the manufacturer offers loaner units. Loaners allow you to resume production quickly while the faulty component is repaired or replaced, minimizing disruption.

RMA Process (Return Merchandise Authorization)

Breakdowns are stressful, so the process for returning defective parts should be simple and transparent. Look for a clearly documented RMA procedure with predictable turnaround times. This shows that the manufacturer takes accountability seriously.

Spare parts are the lifeline of any laser cutting operation. The best manufacturers back their machines with a solid stocking policy, transparent lead times, stable pricing, and practical solutions like loaners and efficient RMAs. Don’t take parts availability for granted—investigating the reality of spare parts now will save you from costly downtime later.

Software Ecosystem and Data Governance

Modern laser cutting machines are no longer just hardware—they’re part of a software-driven ecosystem that determines how efficiently you design, program, and monitor jobs. The software layer touches everything from machine optimization to data security, yet it’s often overlooked during the buying process. Evaluating a manufacturer’s approach to software and data governance is crucial for ensuring your machine works seamlessly today and stays relevant tomorrow.

Ownership

Clarify who actually owns the software running your machine. Some vendors provide permanent licenses bundled with the equipment, while others only grant usage rights. Ownership affects your ability to keep using the software if contracts expire or the vendor exits the market.

Update Cadence and Changelogs

Software is never static. Ask how often updates are released and whether the manufacturer publishes changelogs detailing improvements, bug fixes, or new features. A predictable update cadence signals that the vendor actively supports and improves its ecosystem.

Licensing Model

Understand the cost structure: perpetual license, subscription, or pay-per-use. Subscriptions may seem affordable upfront, but can add significant recurring costs over time. Transparent licensing helps you budget for long-term operations.

APIs and Integration

Your machine shouldn’t be a silo. Look for open APIs or integration options with ERP, MES, or CAD/CAM systems. This ensures you can connect the laser cutter to your broader digital workflow rather than being locked into a closed ecosystem.

Data Control

Laser cutting machines often generate valuable production data. Clarify whether you own this data or if it’s stored in the vendor’s cloud. Ideally, you should retain control and have the option to export or analyze data without restrictions.

Cybersecurity Posture

Connected machines can be vulnerable to cyber threats. Ask about the manufacturer’s cybersecurity standards, patching policies, and data encryption methods. A strong cybersecurity posture reduces risk to both your production and sensitive customer information.

The right software ecosystem can extend the life of your machine, integrate it into your production flow, and protect your data. By evaluating ownership, updates, licensing, integration options, data policies, and cybersecurity practices, you ensure that your investment is future-proof, secure, and aligned with your business goals.

Quality Systems and Compliance Maturity

Behind every reliable laser cutting machine is a disciplined quality system. Specifications may look impressive on paper, but without strong process control and compliance practices, performance in the field can vary dramatically. Evaluating a manufacturer’s quality systems and compliance maturity helps you separate those who build machines to last from those who simply assemble components.

Certifications

Start by confirming whether the manufacturer holds recognized certifications such as ISO 9001 (quality management), ISO 14001 (environmental management), or ISO 45001 (occupational health and safety). These aren’t just plaques on the wall—they demonstrate a structured approach to consistent production, continuous improvement, and compliance with international standards.

Process Control

Ask how the manufacturer monitors and documents production processes. Do they track tolerances on critical assemblies? Are corrective actions logged and reviewed? A mature process control system minimizes variability and ensures that every machine shipped performs consistently.

Outgoing Inspection

Quality doesn’t end at assembly. Robust manufacturers conduct detailed outgoing inspections—verifying laser alignment, cutting performance, and software integrity before shipping. This step reduces the risk of you becoming the “final inspector” once the machine arrives at your shop.

Safety Documentation

Laser cutting systems involve high power, optics, and often hazardous fumes. The manufacturer should provide clear safety documentation, operator manuals, and hazard assessments aligned with CE, FDA, or other regulatory frameworks. If documentation is weak or generic, it’s a warning sign.

Regulated Industry Support

If you operate in industries such as aerospace, automotive, or medical devices, compliance requirements are even stricter. A qualified manufacturer should be able to support traceability, documentation packages, and validation processes needed for these sectors. Not every vendor is equipped for this level of rigor—verify early.

Strong quality systems and compliance maturity are the foundation of long-term reliability and safety. Certifications confirm structure, process controls ensure consistency, inspections catch defects before delivery, and documentation supports safe operation. For regulated industries, compliance capabilities are non-negotiable. By probing into these areas, you can quickly distinguish between manufacturers who build for precision and accountability versus those who cut corners.

Financial Stability and Strategic Risk

Buying laser cutting machines isn’t just a transaction—it’s a long-term partnership. The machine may run for 10 to 15 years, and during that time you’ll rely on the manufacturer for parts, upgrades, and service. That’s why evaluating a company’s financial stability and strategic risk is critical. A vendor with shaky finances or short-term priorities may leave you stranded when you need them most.

Ownership and Governance

Who owns the manufacturer? Is it privately held, publicly traded, or part of a larger conglomerate? Ownership and governance structures shape decision-making. Family-owned businesses may focus on legacy and stability, while private equity-backed firms may prioritize short-term returns. Understanding governance helps you assess whether the company is managed for long-term continuity or short-term gains.

Revenue Mix

Look at how the company earns its money. A healthy revenue mix includes machine sales, service contracts, spare parts, and possibly software. If a manufacturer relies too heavily on one revenue stream—like new machine sales—it may struggle in downturns. Balanced revenue signals resilience.

R&D Investment

Laser technology evolves quickly. Strong manufacturers consistently reinvest in R&D to improve cutting speed, efficiency, software, and automation. Ask what percentage of annual revenue is dedicated to R&D, and request examples of innovations introduced in recent years. High investment in R&D is a marker of future viability.

Parts Lifecycle Policy

A machine is only as good as its support over time. Investigate the manufacturer’s parts lifecycle policy—how long they guarantee availability of consumables, components, and software support after a model is discontinued. A transparent lifecycle policy protects you from being forced into premature upgrades or scrambling for obsolete parts.

Financial stability is just as important as technical capability. Ownership and governance reveal long-term priorities, revenue mix shows resilience, R&D investment signals future readiness, and lifecycle policies safeguard your ability to keep machines running. By examining these factors, you minimize the risk of investing in a machine backed by a partner who might not be there when you need them most.

Training Depth and Change-Management Culture

Laser cutting machines are only as effective as the people who run them. Even the most advanced system won’t deliver results if your team isn’t trained to use it properly or adapt to the changes it brings. That’s why evaluating a manufacturer’s training depth and change-management culture is just as important as looking at specs and service. A vendor that invests in comprehensive training and structured adoption support ensures you unlock the full value of your investment.

Curricula

Ask what formal training programs the manufacturer provides. A mature curriculum should cover machine operation, software programming, routine maintenance, safety protocols, and troubleshooting. The best vendors also offer role-specific training—for operators, programmers, and maintenance staff—so each team member builds the skills they need.

Formats

Different businesses learn in different ways. Look for training offered in multiple formats: onsite sessions during installation, classroom-style workshops, e-learning modules, and video libraries. Flexible delivery methods help your team absorb knowledge at their own pace and revisit material when needed.

Artifacts

Training shouldn’t end when the trainer leaves. Manuals, quick-reference guides, maintenance checklists, and knowledge bases act as artifacts that reinforce learning. Evaluate whether the vendor provides clear, practical documentation that your team can actually use on the shop floor.

Post-Go-Live Support

The real test begins after the machine is up and running. Does the manufacturer offer refresher training, advanced modules, or periodic skills audits? Do they have a hotline or remote support channel dedicated to answering “how-to” questions? Strong post-go-live support helps your team adapt as production demands evolve.

Training depth and change-management culture directly impact how quickly your investment pays off. Comprehensive curricula, flexible formats, lasting artifacts, and ongoing support give your staff the confidence to run machines safely, efficiently, and creatively. A manufacturer that treats training as an ongoing partnership—not a one-time event—will help your organization adapt, improve, and thrive long after installation.

Safety Culture You Can Feel (and Measure)

Laser cutting machines are powerful tools—combining high-energy beams, moving parts, pressurized gases, and often hazardous fumes. That power comes with risk. Choosing a manufacturer with a strong safety culture isn’t just about compliance; it’s about protecting your people, your facility, and your reputation. The best vendors embed safety into every stage of their process, and you should be able to both feel it in their approach and measure it in their practices.

Engineering and Design Practices

Safety starts with how the machine is built. Look for features such as interlocked doors, emergency stop circuits, fume extraction systems, and clear operator interfaces. Ask how safety is considered during design reviews and whether the manufacturer exceeds, not just meets, baseline regulatory requirements.

Documentation and Standards

A strong safety culture shows up in the paperwork. The manufacturer should provide detailed manuals, risk assessments, and hazard labels aligned with CE, FDA, or ANSI standards. Incomplete or generic documentation is a red flag that safety is treated as an afterthought.

Operator Training and Awareness

Safety isn’t just hardware—it’s behavior. Evaluate whether the vendor includes safety-focused training modules for operators, maintenance staff, and supervisors. Do they provide refreshers or audits after installation? Companies that prioritize safety will make sure your team knows how to avoid risks and respond quickly if something goes wrong.

Metrics and Track Record

Safety culture can be measured. Ask about the manufacturer’s incident history, near-miss reporting, or third-party safety audits. Transparent vendors won’t hesitate to share how they track and improve safety performance across their installed base.

Integration into Regulated Environments

If you serve aerospace, medical, or automotive industries, the bar for safety is even higher. A qualified manufacturer should be able to support validation, traceability, and documentation to meet these strict standards without compromise.

Safety culture is more than a checklist—it’s a mindset. You can feel it in how openly a manufacturer talks about safety, and you can measure it in their design choices, documentation, training programs, and track record. Choosing a partner with a strong safety culture protects your people and strengthens your operations for the long term.

Global Footprint, Localization, and Cultural Fit

Laser cutting machine manufacturing is a global business. You may buy from a company headquartered on the other side of the world, but what matters day to day is how well that vendor’s footprint aligns with your operations. A manufacturer’s ability to localize their offering—through language, documentation, time-zone coverage, and cultural fit—can be the difference between smooth collaboration and constant frustration.

Language and Documentation

Technical accuracy depends on clear communication. Insist on manuals, training materials, and service documentation in the primary language of your operators. Poor translations or generic documents can lead to misunderstandings, unsafe practices, and wasted time. The strongest manufacturers invest in professional localization, ensuring terminology is consistent and instructions are usable in your context.

Time-Zone Alignment

When machines go down, waiting for answers from a support team on the other side of the world can cost you dearly. Evaluate whether the manufacturer has local or regional service centers that align with your working hours. Even better, confirm if they provide “follow-the-sun” support models, where different offices around the globe hand off responsibilities to ensure coverage 24/7.

Cultural Expectations

Business is shaped by culture as much as by contracts. Some vendors operate with rigid hierarchies, while others prioritize rapid escalation and direct problem-solving. Some may assume customers prefer written communication; others lean on verbal updates. Understanding whether a vendor’s working style matches your company’s culture—decision-making speed, escalation comfort, transparency—will save frustration down the line.

A manufacturer’s global footprint and ability to localize support are just as important as the machines they build. Clear documentation in your language, responsive support aligned with your time zone, and a cultural fit with your way of doing business all contribute to a stronger partnership. The right vendor won’t just deliver equipment—they’ll adapt to your environment so collaboration feels natural and productive.

Contractual Protections: Put Accountability in Writing

Buying laser cutting machines is not just about equipment—it’s a major business contract. The machine itself may look impressive on the factory floor, but what really protects your investment is what’s written in the agreement. Strong contracts shift vague promises into enforceable obligations and give you leverage if things don’t go as planned. Before signing, ensure the contract includes clear protections around warranties, service expectations, software, and parts support.

Warranty Clarity

Not all warranties are equal. Scrutinize the coverage: Does it include labor as well as parts? Are consumables excluded? How long is the coverage for critical components like the laser source? Clear warranty language prevents finger-pointing when failures occur.

Service Level Agreement (SLA)

A verbal promise of “fast service” is meaningless without specifics. A proper SLA should outline response times, escalation steps, and remedies if commitments aren’t met. For high-volume operations, these guarantees can make the difference between hours and days of downtime.

Acceptance Criteria

Define upfront what “success” looks like during installation. Acceptance criteria might include cut quality benchmarks, machine uptime targets during the trial period, or software integration performance. Without documented criteria, disputes over machine performance become subjective.

Software Terms

Software is an integral part of today’s machines, so contracts should address licensing, update rights, and data ownership. Make sure you understand whether licenses are perpetual or subscription-based, what happens if the vendor stops supporting your version, and how your data is handled.

Parts Pricing and Availability

Parts can become a hidden cost trap. Lock in transparency on pricing policies and availability commitments. Some buyers negotiate caps on annual price increases or guaranteed stocking periods for key components to avoid surprises down the road.

Change Control

Manufacturers evolve their product lines, but changes should not leave you unsupported. A clear change-control clause ensures the vendor will notify you of product discontinuations, provide backward compatibility where possible, and maintain parts availability for a defined period.

Contracts are where accountability is secured. Warranty clarity, enforceable SLAs, objective acceptance criteria, fair software terms, transparent parts policies, and structured change control turn a risky purchase into a managed partnership. By putting these protections in writing, you safeguard your investment and ensure the manufacturer stands behind their promises long after the ink is dry.

Due Diligence You Can Actually Run

Choosing laser cutting machine manufacturers is a high-stakes decision—one that shouldn’t be based on glossy brochures or polished sales pitches alone. Real confidence comes from running your own due diligence drills to see how a vendor performs under real-world conditions. By testing their service, parts support, software ecosystem, training depth, and even their factory operations, you separate manufacturers who can truly deliver from those who only talk a good game.

Service Drill

Before buying, place a mock service call. Track how quickly the vendor responds, how knowledgeable the support staff is, and how clearly they communicate solutions. This small test will reveal more about their service culture than any marketing claim.

Parts Drill

Request a quote and lead time for a non-critical spare part. Monitor how fast they respond, whether pricing feels transparent, and if availability matches their promises. If they struggle here, expect worse during actual downtime.

Software Drill

Ask for a trial license, demo environment, or sample update log. See how intuitive the interface is, how often updates are released, and whether documentation is usable. This ensures you won’t be locked into clunky software or unpredictable upgrade cycles.

Training Drill

Request training outlines, sample materials, or access to a recorded module. Gauge the professionalism of their curricula and whether they address operator, maintenance, and safety needs. Vendors serious about training will gladly show you the depth of their resources.

Factory Audit

If possible, visit the manufacturer’s factory or audit virtually. Look for evidence of structured production processes, outgoing inspection, and safety culture. A quick walk-through often reveals whether quality is built into their DNA—or left to chance.

Due diligence doesn’t have to be abstract. By running targeted drills—service, parts, software, training, and factory—you test the vendor’s capabilities in practical, measurable ways. The results will either reinforce your confidence or expose gaps before you sign a contract. This hands-on approach ensures you’re partnering with a manufacturer who can support your operations long after the machine is delivered.

Shortlisting and Scoring

By the time you’ve gathered information on multiple laser cutting machine manufacturers, the challenge shifts from exploration to comparison. With so many dimensions—service, parts, software, compliance, and more—it’s easy to lose clarity. That’s where a structured shortlisting and scoring process makes all the difference. Instead of relying on gut feel or flashy demos, you use weighted criteria to objectively rank vendors against what matters most to your business.

Service Capacity (Weight High)

Service should carry the most weight in your scoring system. A machine is only as valuable as the uptime it delivers, and strong field service coverage with proven responsiveness is non-negotiable. Give service capacity the highest score weighting.

Parts Logistics

Evaluate stocking policies, depot locations, lead-time transparency, and pricing stability. A vendor with robust logistics ensures you’re not sidelined by preventable parts delays.

Software Strength

Score vendors on ownership clarity, licensing models, update cadence, integration flexibility, and cybersecurity posture. Machines are increasingly software-driven, and weak ecosystems limit long-term value.

Quality System Maturity

Consider certifications, process control, outgoing inspections, and safety documentation. A manufacturer with mature quality systems produces machines that perform consistently, not variably.

Financial/Strategic Stability

Assess governance, revenue mix, R&D investment, and lifecycle policies. A stable, forward-looking company is far less likely to leave you unsupported mid-lifecycle.

Training and Change Management

Measure the depth of curricula, delivery formats, artifacts, and post-go-live support. Training directly impacts how quickly your team can achieve productivity gains and sustain safe operation.

Compliance Capability

Particularly if you serve regulated industries, verify the vendor’s ability to support documentation, traceability, and validation. This is often a pass/fail criterion in your scoring matrix.

Cultural Fit and Communication

Finally, factor in localization, time-zone alignment, and cultural expectations. A technically strong vendor who cannot communicate effectively or adapt to your working style may prove difficult to partner with long-term.

A disciplined shortlisting and scoring process allows you to compare vendors fairly and transparently. By weighting service highest and layering in factors like parts logistics, software strength, quality, stability, training, compliance, and cultural fit, you create a balanced scorecard that aligns with your real-world priorities. The outcome is a shortlist of manufacturers who not only meet your technical needs but also fit your business strategically and operationally.

Total Cost of Partnership (TCP), Not Just TCO

When evaluating laser cutting machine manufacturers, many buyers focus on Total Cost of Ownership (TCO)—the sum of purchase price, consumables, energy usage, and service contracts over the machine’s life. TCO is important, but it’s not the whole picture. A more complete lens is the Total Cost of Partnership (TCP)—the long-term value (or drag) created by your relationship with the manufacturer. Machines may look affordable on paper, but the partnership behind them often determines the true cost.

OpEx Halo

A strong manufacturer can reduce your operating expenses by streamlining workflows, optimizing consumables, and offering training that improves throughput. Conversely, a weak partner may drive up your OpEx through inefficient processes and hidden costs.

Downtime Delta

The gap between promised and actual service performance translates directly into lost revenue. TCP accounts for how a vendor’s service capacity, spare parts strategy, and escalation ladder affect your downtime risk—and therefore your profitability.

Upgrade Path

Future-proofing matters. Some manufacturers offer modular upgrades, retrofits, and software enhancements, extending machine life. Others force premature replacement cycles. A clear upgrade path lowers lifecycle costs and protects your investment.

Data Portability

Your production data is valuable. TCP includes whether you can freely export, analyze, and migrate data—or whether you’re locked into a proprietary ecosystem. Lack of portability can add hidden costs when integrating with other systems or switching vendors later.

Residual Value

Machines from stable, reputable manufacturers often hold higher resale or trade-in value. Weak brands, or those with poor support records, depreciate faster. Residual value should be factored into your economic model of long-term ownership.

TCO looks at the machine. TCP looks at the partnership. By factoring in OpEx efficiencies, downtime risk, upgrade flexibility, data portability, and residual value, you’ll see the full financial impact of your choice. The right manufacturer doesn’t just sell you laser cutting machines—they reduce operational friction, protect your investment, and deliver value across the entire partnership.

Summary

Choosing the right laser cutting machine manufacturer is not just about comparing machine specs or chasing the lowest price. It’s about finding a partner who can support your business for the long haul. From the start, focus on partner fit rather than product features alone—because the true differentiators are service capacity, spare parts availability, training depth, and cultural alignment.

Understanding vendor types (OEMs, branders, distributors) helps you set expectations on innovation and support. Evaluating their field service footprint, spare parts reality, and software ecosystem gives you a clear picture of how downtime, upgrades, and integration will actually be handled. Beyond technology, dig into quality systems, compliance maturity, and financial stability—factors that determine whether the company will still be standing behind its machines years from now.

Practical steps like running due diligence drills and applying a structured shortlisting and scoring method ensure you’re comparing vendors on substance, not salesmanship. And when it comes to economics, think in terms of Total Cost of Partnership (TCP), which reflects the ongoing value—or risk—a manufacturer brings.

In the end, the best manufacturer isn’t just selling you a machine. They’re providing uptime, adaptability, and confidence. Choose the partner who proves they can deliver all three.

Get Laser Cutting Solutions

After weighing all the factors—service capacity, spare parts, software, compliance, and long-term stability—the next step is to choose a partner who can deliver not just machines, but complete solutions. That’s where AccTek Group stands out. As a professional manufacturer of intelligent laser equipment, AccTek Group combines engineering expertise with a commitment to customer success, helping businesses across industries unlock the full potential of laser cutting technology.

AccTek Group offers a comprehensive portfolio of solutions, from high-precision fiber laser cutting machines to automated systems designed for scalable production. Beyond the equipment itself, the company invests heavily in R&D, ensuring customers benefit from cutting-edge features, smarter software integration, and future-ready upgrade paths. Just as importantly, AccTek Group supports its machines with robust service networks, localized training programs, and transparent spare parts strategies—minimizing downtime and maximizing productivity.

Every business has unique needs, and AccTek Group takes a partnership approach to tailor solutions for different materials, production volumes, and workflow challenges. Whether you’re looking to improve efficiency, expand capacity, or transition into intelligent manufacturing, AccTek Group provides the technology and the expertise to make it happen.

When choosing laser cutting machine manufacturers, don’t just buy equipment—secure a long-term solution. With AccTek Group, you get both.