How Accurate Is Laser Marking

This article explores how laser marking achieves superior precision, the factors that influence this precision, and how various industries ensure consistent, high-quality, and permanent markings.

Laser Welding Brass Guide

This article is a comprehensive guide to brass laser welding, covering welding techniques, parameters, challenges, equipment selection, and best practices for achieving precise, high-quality welds.

What Are the Common Problems With Laser Cleaning Machines

This article addresses the most common problems with laser cleaning machines, including performance issues, maintenance challenges, and practical solutions for reliable operation.

Is Laser Cutting Fume Toxic

This article explains what laser cutting fumes are, how they form, their health and environmental risks, and the safety measures needed for proper fume control and extraction.

Stepper Motor VS Servo Motor

This article compares stepper motors and servo motors, detailing their working principles, performance characteristics, applications, and key differences in modern automation.

How To Maintain Laser Marking Machines

This article provides a comprehensive guide to maintaining your laser marking machine, including cleaning, inspection, cooling system care, and troubleshooting to ensure consistent operation and durability.

Autogenous VS Filler Laser Welding

This article explains the differences between autogenous and filler laser welding, detailing their principles, processes, parameters, and applications in industrial manufacturing.

What Precautions Should Be Taken During Laser Cleaning

This article explains key precautions for safe laser cleaning, covering equipment setup, operator protection, ventilation, maintenance, and compliance with safety standards.

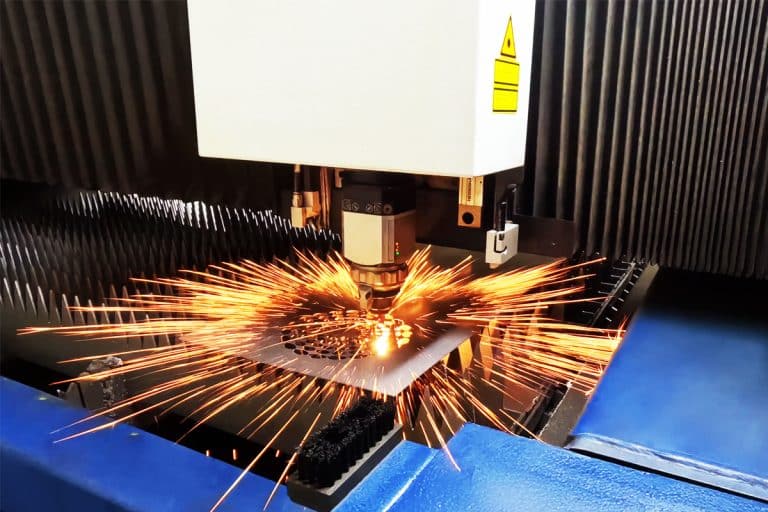

Laser Cutting Machine Nozzle Guide

This article is a comprehensive guide explaining laser cutting machine nozzles – their types, functions, materials, maintenance, and best practices for achieving precise, efficient cutting results.

What Are the Risks of Using Oscillating Knife Cutting Machines

This article explores the potential risks of using oscillating knife cutting machines, including mechanical, electrical, ergonomic, and operational hazards, and how to manage them safely.

How Accurate Is Laser Marking

This article explores how laser marking achieves superior precision, the factors that influence this precision, and how various industries ensure consistent, high-quality, and permanent markings.

Laser Welding Brass Guide

This article is a comprehensive guide to brass laser welding, covering welding techniques, parameters, challenges, equipment selection, and best practices for achieving precise, high-quality welds.

What Are the Common Problems With Laser Cleaning Machines

This article addresses the most common problems with laser cleaning machines, including performance issues, maintenance challenges, and practical solutions for reliable operation.

Is Laser Cutting Fume Toxic

This article explains what laser cutting fumes are, how they form, their health and environmental risks, and the safety measures needed for proper fume control and extraction.

Stepper Motor VS Servo Motor

This article compares stepper motors and servo motors, detailing their working principles, performance characteristics, applications, and key differences in modern automation.

How To Maintain Laser Marking Machines

This article provides a comprehensive guide to maintaining your laser marking machine, including cleaning, inspection, cooling system care, and troubleshooting to ensure consistent operation and durability.

Autogenous VS Filler Laser Welding

This article explains the differences between autogenous and filler laser welding, detailing their principles, processes, parameters, and applications in industrial manufacturing.

What Precautions Should Be Taken During Laser Cleaning

This article explains key precautions for safe laser cleaning, covering equipment setup, operator protection, ventilation, maintenance, and compliance with safety standards.

Laser Cutting Machine Nozzle Guide

This article is a comprehensive guide explaining laser cutting machine nozzles – their types, functions, materials, maintenance, and best practices for achieving precise, efficient cutting results.

What Are the Risks of Using Oscillating Knife Cutting Machines

This article explores the potential risks of using oscillating knife cutting machines, including mechanical, electrical, ergonomic, and operational hazards, and how to manage them safely.