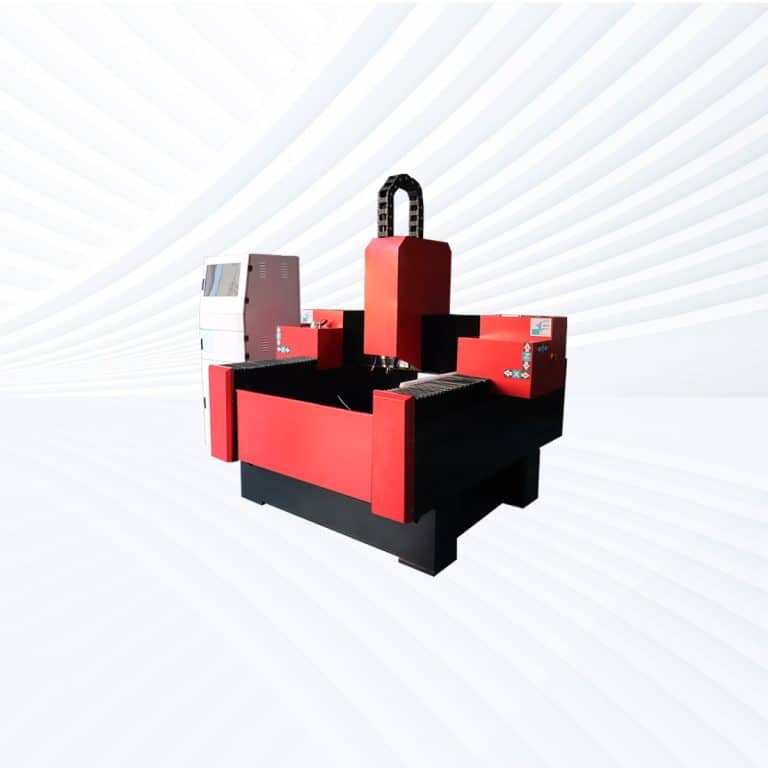

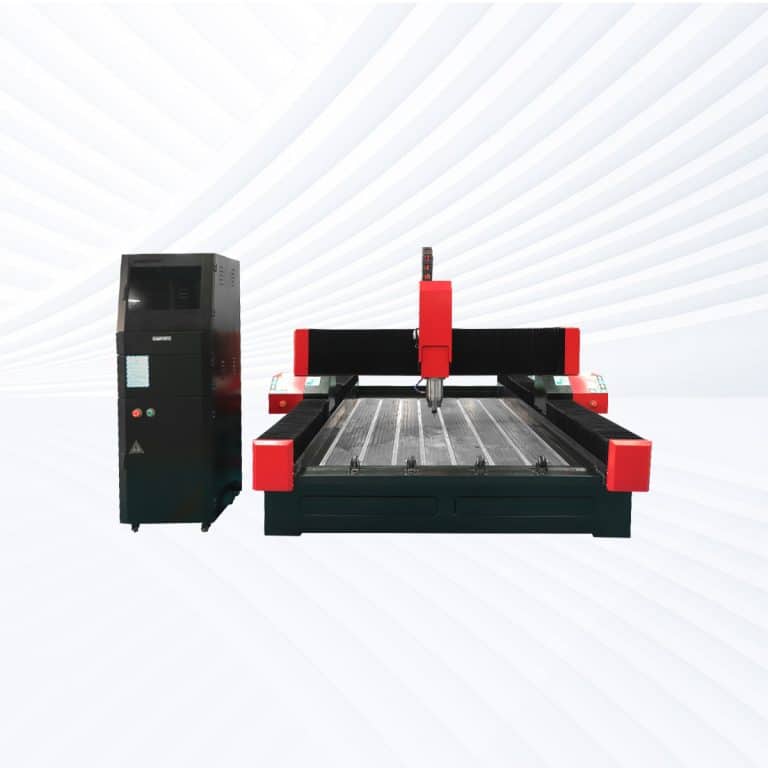

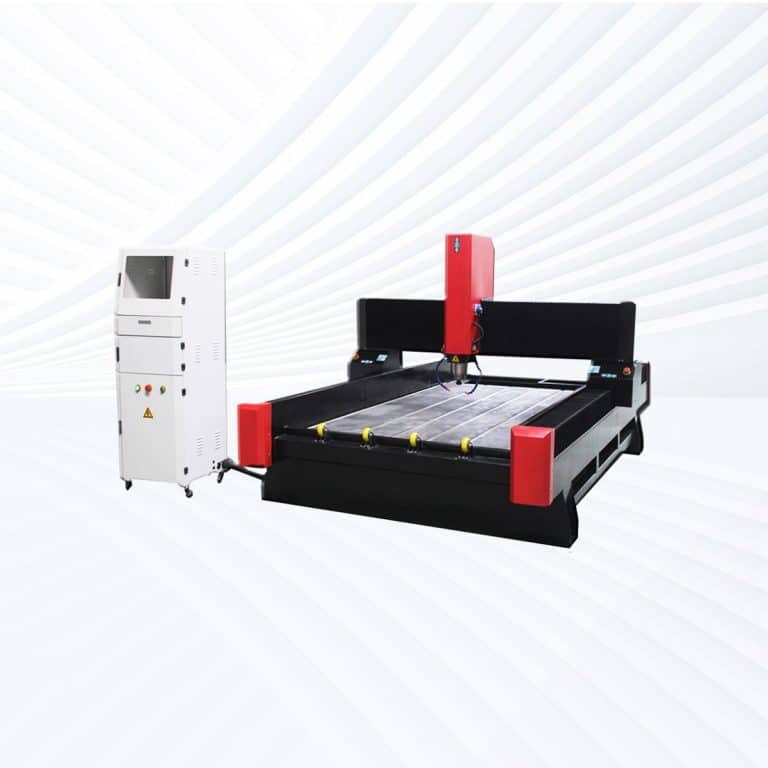

Product Introduction

Benefits of CNC Routing Stone

High Precision and Accuracy

Stone CNC routers deliver clean, chip-free edges and accurate engravings, even on dense materials like granite or marble. Advanced motion controls and diamond tooling ensure consistency, making them ideal for intricate patterns, lettering, and high-tolerance architectural elements.

Versatility Across Stone Types

From granite and marble to engineered quartz, travertine, and ceramic tiles, CNC routers can process a wide variety of stones. This versatility allows manufacturers to produce countertops, flooring, monuments, and decorative pieces with equal ease and quality.

Increased Productivity

Automated CNC routing significantly reduces production times compared to manual carving or cutting. Complex designs and large-scale projects can be completed quickly, enabling businesses to handle higher volumes while maintaining accuracy and reducing labor costs.

Consistency and Repeatability

Once programmed, CNC routers reproduce the same design flawlessly across multiple pieces. This repeatability is crucial for batch production of stone products such as wall panels, tiles, and countertops, where uniform quality is essential.

Enhanced Design Flexibility

Stone CNC routers allow the creation of detailed engravings, 3D carvings, and customized shapes that are difficult or impossible with manual tools. This capability opens new opportunities in architecture, interior design, and artistic stone applications.

Reduced Material Waste

By optimizing cutting paths and ensuring precise execution, CNC routers minimize stone waste. This efficiency not only lowers material costs—especially valuable with premium stones—but also contributes to more sustainable and cost-effective manufacturing practices.

Compatible Stone Materials

- Granite

- Marble

- Quartz

- Quartzite

- Limestone

- Travertine

- Sandstone

- Slate

- Basalt

- Onyx

- Soapstone

- Bluestone

- Serpentine

- Alabaster

- Dolomite Stone

- Gabbro

- Schist

- Conglomerate Stone

- Diorite

- Andesite

- Rhyolite Stone

- Jasper Stone

- Obsidian

- Feldspar Stone

- Calcite Stone

- Tufa Stone

- Pumice Stone

- Porphyry Stone

- Syenite

- Phyllite

- Pegmatite Stone

- Engineered Quartz

- Terrazzo

- Ceramic Tiles

- Porcelain Tiles

- Mosaic Stone Panels

- Agglomerated Marble

- Cultured Stone Veneers

- Artificial Granite Panels

- Composite Stone Slabs

Application of Stone CNC Routers

Customer Testimonials

Comparison VS Other Engraving Technologies

| Feature | Stone CNC Router | Laser Engraving | Hand Engraving | Chemical Etching |

|---|---|---|---|---|

| Cutting Depth | Deep, variable 2D & 3D | Shallow, surface only | Variable, depends on artisan | Very shallow, surface-level |

| Precision | High accuracy, chip-free edges | Fine surface detail, risk of burns/cracks | Inconsistent, artisan-dependent | Moderate, depends on stencil/mask |

| Speed | Fast for large/complex jobs | Very fast for surface patterns | Slow, labor-intensive | Moderate, multi-step process |

| Material Compatibility | Granite, marble, quartz, engineered stone, tiles | Limited, can crack heat-sensitive stones | Any stone, but very slow | Works only on some stones |

| Complex Designs | Handles 2D/3D carvings, engravings, drilling | Excellent for 2D surface marks | Limited by artisan skill | Restricted to flat designs |

| Repeatability | Perfectly repeatable via CAD | Repeatable for shallow marks | Hard to replicate identically | Repeatable if masks identical |

| Setup Requirements | CAD/CAM software, diamond tooling, water cooling | Software, laser calibration | Hand tools & years of practice | Chemical baths, masking, safety gear |

| Learning Curve | Moderate, training required | Moderate, software-based | Very steep, artisan skill needed | Moderate, process-sensitive |

| Production Volume | Ideal for prototypes & mass production | Medium runs, surface-only | Poor, suited for one-offs | Suitable for batch processing |

| Surface Finish | Smooth, polished, professional | Burn marks, surface cracks possible | Handmade texture | Matte, less crisp |

| Durability of Work | Long-lasting structural carvings | Surface-only, may fade | Durable but inconsistent | Shallow, less durable |

| Customization | Easy to modify via CAD files | Quick digital adjustments | Manual, slow & limited | Requires new masks per design |

| Waste & Safety | Minimal waste, safe with water/dust control | Minimal waste, risk of fumes | No waste, but laborious | Hazardous chemicals, disposal needed |

| Cost Efficiency | Higher upfront, low per-part | Moderate setup, limited applications | Low tool cost, high labor cost | Low equipment cost, high consumables |

| Best Use Case | Countertops, monuments, tiles, 3D carvings | Logos, shallow surface patterns | Artistic, unique stonework | Industrial coding & shallow markings |

Why Choose Us

High Precision & Efficiency

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Robust and Durable Design

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Intelligent Control Systems

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

Flexible Customization

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

Related Resources

What Is The Accuracy Of CNC Routers

This article is a comprehensive guide that explains the precision of CNC routers, the key factors affecting precision, expected performance, and how to improve machining results.

How to Choose the Right Router Bits for CNC Routers

This article explains how to select the right router bit for your CNC router, including cutter type, material, coating, and tip, to achieve precise, efficient, and durable cutting performance.

Stepper Motor VS Servo Motor

This article compares stepper motors and servo motors, detailing their working principles, performance characteristics, applications, and key differences in modern automation.

How to Choose the Right CNC Router Spindle

This article explains how to choose the right CNC router spindle by detailing key factors such as power, torque, speed range, cooling type, precision, and machine compatibility.

Frequently Asked Questions

How Much Do Stone CNC Routers Cost?

- Stone CNC Routers: $6,000–$7,500

- Machines in this price range are designed for durability, with reinforced frames that reduce vibration and wear.

- They typically feature water-cooled spindles, as water is essential not only for cooling but also for dust suppression when working with stone.

- Standard models handle tasks like countertop shaping, decorative stone carving, memorial engraving, and tile patterning.

- Factors Affecting Price:

- Spindle Power and Cooling: Higher spindle wattage and advanced water-cooling systems add to cost but improve efficiency when cutting dense stone.

- Work Area Size: Larger beds that can hold full stone slabs are more expensive than compact machines.

- Frame Quality: Heavy-duty, vibration-resistant steel frames cost more but extend machine life and improve accuracy.

How Accurate Are Stone CNC Routers?

- Engraving and Carving Accuracy: Stone CNC routers can typically achieve an accuracy of ±0.05–0.1 mm, depending on the machine’s build quality and spindle system. This precision allows for detailed text engraving, decorative designs, and 3D relief carving on stone surfaces.

- Cutting Accuracy: For cutting and shaping, accuracy depends on both tool sharpness and the stability of the machine frame. Heavy-duty CNC routers maintain consistent precision when cutting countertops, sink holes, or architectural stone components, often delivering tolerances tight enough for seamless installation.

- Repeatability: A key factor in accuracy is repeatability—the ability to produce identical results across multiple runs. Well-calibrated stone CNC routers ensure high repeatability, critical for batch production of tiles, plaques, or patterned panels.

- Factors Influencing Accuracy:

- Machine Rigidity: Rigid steel or cast-iron frames minimize vibration when cutting dense stone.

- Tooling Quality: Diamond-coated or solid diamond tools are essential for maintaining precision and avoiding edge chipping.

- Cooling and Lubrication: Water cooling helps maintain spindle stability and reduces thermal expansion, improving cut accuracy.

- Operator Setup: Proper calibration, toolpath programming, and material clamping directly affect accuracy outcomes.

What Are The Disadvantages Of Stone CNC Routers?

- High Initial Investment: Stone CNC routers typically cost $6,000–$7,500 or more, depending on size and features. For small shops or startups, this can be a significant upfront cost, especially when factoring in tooling and auxiliary systems such as water-cooling pumps.

- Tool Wear and Replacement Costs: Cutting stone requires diamond-coated or solid diamond tools, which are expensive and wear out faster than tools used for softer materials. Regular tool replacement adds to operating costs and downtime.

- Heavy Machine Structure: Because of the hardness of stone, these CNC routers must have extremely rigid frames, often made of steel or cast iron. This makes them bulky and heavy, requiring more space and sometimes reinforced flooring for installation.

- Water and Cooling Requirements: Stone machining generates high friction and heat. Continuous water cooling is essential to prevent tool breakage and dust generation. This means users must invest in water recycling systems and manage slurry disposal, which adds to maintenance complexity.

- Slower Cutting Speeds: Compared to wood or plastic CNC routers, stone CNC routers operate at slower speeds due to the density of the material. This increases production time, particularly for detailed engravings or large-scale cutting projects.

- Maintenance and Cleaning: Stone dust and slurry can clog machine parts and damage bearings, spindles, and linear rails. Regular cleaning and lubrication are essential, making maintenance more time-consuming than with CNC routers used for softer materials.

- Limited Material Versatility: While stone CNC routers excel at cutting granite, marble, and similar materials, they are less versatile for other applications. Shops that work with multiple material types often need additional machines for wood, plastics, or metals.

- Energy Consumption: These CNC routers use powerful spindles (often water-cooled) and heavy-duty motors, which consume more energy than smaller CNC systems, raising long-term operating costs.

What Is The Life Expectancy Of Stone CNC Routers?

- Frame and Machine Structure: The structural components of stone CNC routers, usually made from steel or cast iron, can last 15–20 years or more if properly maintained. These parts are highly durable since they are built to withstand the vibrations and forces of machining hard stone.

- Spindle Life: The spindle, whether air-cooled or water-cooled, has a shorter life than the machine frame. Under regular stone routing conditions, a spindle may last 3–5 years before requiring replacement or major servicing. Continuous water cooling is essential to maximize spindle lifespan when cutting dense materials like granite.

- Guide Rails and Bearings: Linear guide rails, ball screws, and bearings can last 8–10 years with regular lubrication and cleaning. However, the slurry from stone cutting can accelerate wear if dust and abrasive particles are not effectively managed through proper sealing and maintenance.

- Motors and Electronics: Stepper motors or servo motors typically last 7–10 years under normal loads. Control electronics and drivers can also last about a decade, but they are sensitive to dust, moisture, and electrical surges, requiring stable operating conditions.

- Tools and Consumables: Diamond tools, unlike the machine itself, wear out quickly. Their lifespan is usually measured in hours of cutting, depending on material hardness and cooling efficiency. Frequent tool replacement is a normal part of operating stone CNC routers.

- Maintenance Impact: With regular cleaning, lubrication, cooling system checks, and replacement of worn components, a stone CNC router can operate efficiently for 10–15 years on average. Heavy-duty industrial models used continuously in stone fabrication shops often reach the higher end of this range. Poor maintenance, on the other hand, can reduce lifespan significantly.

How Do I Choose Stone CNC Routers?

- Material Compatibility: Stone CNC routers should be selected based on the types of stone you plan to process. For example, harder materials like granite and quartz require more powerful spindles, stronger frames, and efficient water cooling systems, while softer stones like marble or limestone can be processed with less demanding setups. Ensuring compatibility avoids premature wear and ensures consistent performance.

- Spindle Power and Cooling System: The spindle is critical when cutting stone. Look for machines with high-powered spindles (typically 5.5 kW to 9 kW or higher) to handle dense materials effectively. Water-cooled spindles are generally preferred over air-cooled models for stone routing because they reduce heat buildup, extend tool life, and improve cut quality.

- Machine Bed and Structure: The frame and table must be heavy-duty and reinforced, usually built from steel or cast iron, to withstand vibration and stress from stone machining. A robust structure ensures accuracy and prevents long-term deformation, which is vital when handling large stone slabs.

- Tooling and Automatic Tool Changer (ATC): For workshops that require frequent bit changes (e.g., switching between cutting, drilling, and engraving tools), an ATC-equipped CNC router greatly improves productivity. It reduces downtime and ensures smoother workflow, particularly in high-volume stone fabrication shops.

- Dust and Water Management: Stone routing generates significant dust and slurry. Machines should be equipped with effective water spray systems for cooling and dust suppression, as well as reliable drainage and filtration systems. Without proper management, both operator safety and machine lifespan can be compromised.

- Axis Configuration:

- 3-axis machines are suitable for standard cutting, engraving, and shaping.

- 4-axis machines allow rotary work, such as columns and curved stone surfaces.

- 5-axis machines are ideal for advanced 3D carving, countertop edge profiling, and complex architectural stonework. Choosing the right axis configuration depends on the level of detail and flexibility required.

- Software and Controller: The CNC controller and CAD/CAM software must be user-friendly while supporting the complex toolpaths often required for stone cutting and engraving. Compatibility with industry-standard software ensures efficiency and precision in handling detailed designs.

- After-Sales Support and Parts Availability: Given the harsh working conditions, stone CNC routers require regular maintenance. Selecting a manufacturer or supplier that offers reliable after-sales support, spare parts, and technical training is essential for minimizing downtime and maximizing return on investment.

How Do I Maintain Stone CNC Routers?

- Spindle Maintenance: The spindle is the most critical part of a stone CNC router. Since stone machining generates high heat and resistance, spindles are typically water-cooled. Regularly check water flow, temperature, and coolant quality to prevent overheating. Spindles should also be inspected for abnormal noise or vibration, as this may indicate bearing wear. Preventive care extends spindle life and reduces costly downtime.

- Lubrication of Moving Components: Linear guides, ball screws, and bearings endure heavy loads when cutting dense stone. Routine lubrication is essential to reduce friction and prevent wear. Many machines are equipped with automatic lubrication systems, but these should be checked regularly to confirm proper function. Consistent lubrication ensures smooth, accurate motion of all axes.

- Dust and Water Management: Stone routing produces a large volume of abrasive dust and slurry. Effective water spray systems must be used to cool tools, suppress dust, and reduce wear. After the operation, drainage systems, filters, and collection trays should be cleaned to prevent clogging. Neglecting dust and water management can damage both the machine and its surrounding environment.

- Tool and Bit Care: Cutters and router bits used on stone wear down quickly due to the abrasive nature of the material. Regularly inspect tools for sharpness and replace them before they degrade cutting accuracy. Using the proper tool for the type of stone not only improves quality but also reduces machine stress.

- Machine Bed and Structural Integrity: Because stone is heavy, the worktable and frame should be inspected for alignment, rigidity, and wear. Any looseness or uneven surface can affect precision. Operators should ensure that clamps and fixtures remain secure during cutting to prevent material shifting, which may also strain the machine.

- Cooling and Electrical Systems: The cooling pumps, hoses, and electrical systems must be checked frequently. Leaks in the cooling system or clogged hoses can cause spindle overheating, while faulty wiring or damaged connections can affect machine performance. Preventive inspections minimize the risk of sudden failures.

- Software and Calibration: Routine calibration ensures that the machine maintains high accuracy for engraving, profiling, or cutting stone. Updating the control software and checking axis alignment improves workflow efficiency and reduces programming errors.

What Are The Environmental Requirements For Using Stone CNC Routers?

- Dust and Slurry Management: Stone routing produces large amounts of abrasive dust and wet slurry. To control this, machines must be used with effective water-cooling systems that reduce airborne dust and prevent overheating. Proper drainage and sediment collection systems are also required to manage waste. If water suppression is not used, high-capacity dust extraction is essential to maintain a clean and safe workspace.

- Ventilation and Air Quality: Good ventilation is necessary to maintain a safe environment. Even with water-cooling, fine particles may still escape into the air. Installing industrial exhaust fans, air filters, or dust collectors improves air quality and protects operators from respiratory hazards.

- Stable Power Supply: Stone CNC routers demand consistent electrical power to drive spindles, pumps, and heavy motors. An uninterrupted power supply (UPS) or voltage stabilizer is recommended to protect sensitive electronic components from power fluctuations.

- Temperature and Humidity Control: Like other CNC equipment, stone CNC routers perform best in environments with stable temperatures and moderate humidity. Excessive heat can affect spindle performance and electronic stability, while high humidity may damage electrical systems or promote corrosion. Climate-controlled workshops are ideal for reliable long-term use.

- Water Supply and Filtration: A continuous water supply is essential for cooling, lubrication, and dust suppression. Clean water prevents tool clogging and excessive wear. Filtration systems should be installed to recycle water, reduce operating costs, and comply with environmental standards for waste management.

- Flooring and Load-Bearing Capacity: Stone CNC routers are heavy machines that must be installed on a solid, vibration-free floor capable of bearing their weight and the additional load of stone slabs. Proper leveling prevents machine misalignment and ensures cutting precision.

- Noise and Vibration Control: Stone machining is noisy and can produce strong vibrations. Workshops should have soundproofing measures or be located in industrial zones to minimize disturbance. Anchoring the machine to a reinforced foundation reduces vibration and improves accuracy.

- Waste Disposal Compliance: Stone dust and slurry are not only a workplace hazard but also an environmental concern. Wastewater systems must comply with local regulations for sediment disposal and recycling. Installing a sludge filtration or recycling unit ensures sustainable operation.

What Training Is Required To Operate Stone CNC Routers?

- Machine Operation Basics: Operators must first learn the fundamentals of CNC router operation, including machine startup and shutdown, spindle control, tool calibration, and setting the correct cutting speeds and feeds for stone. Since stone is harder and more brittle than many other materials, proper settings are critical to prevent tool breakage or stone cracking.

- CAD/CAM Software Training: Stone CNC routers rely on CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to create toolpaths for cutting and engraving. Training should include designing patterns, importing 2D/3D files, generating toolpaths, and simulating jobs before actual machining. This ensures precise output and reduces costly mistakes.

- Material Handling and Safety: Stone slabs are heavy and fragile, requiring training in safe lifting, securing, and positioning techniques. Operators should also learn how to clamp or vacuum-hold stone properly to avoid shifting during cutting. Incorrect handling can cause machine damage or safety hazards.

- Tooling and Bit Selection: Stone cutting requires specialized diamond tools and bits. Training should cover tool types, proper installation, tool wear recognition, and replacement procedures. Operators must also learn how to adjust spindle speeds and feeds to maximize tool life and cut quality.

- Water-Cooling and Slurry Management: Unlike wood or plastic routing, stone CNC routers rely on continuous water cooling to suppress dust and reduce heat buildup. Training should include setting up water systems, monitoring flow rates, maintaining pumps, and managing slurry disposal or recycling systems to meet environmental regulations.

- Maintenance Procedures: Routine maintenance, such as lubricating guide rails, cleaning filters, checking coolant pumps, and inspecting electrical components, is essential. Operators should be trained in preventive maintenance tasks to minimize downtime and extend machine lifespan.

- Safety Protocols and PPE Use: Stone routing involves hazards such as flying chips, slurry splashes, and loud noise. Training must cover personal protective equipment (PPE) requirements, including safety goggles, gloves, ear protection, and dust masks when applicable. Emergency stop procedures and safe workspace practices should also be emphasized.

- Troubleshooting and Problem-Solving: Finally, operators must learn to diagnose common problems, such as tool breakage, vibration, uneven cuts, or water supply issues. Quick troubleshooting skills help maintain productivity and reduce errors.