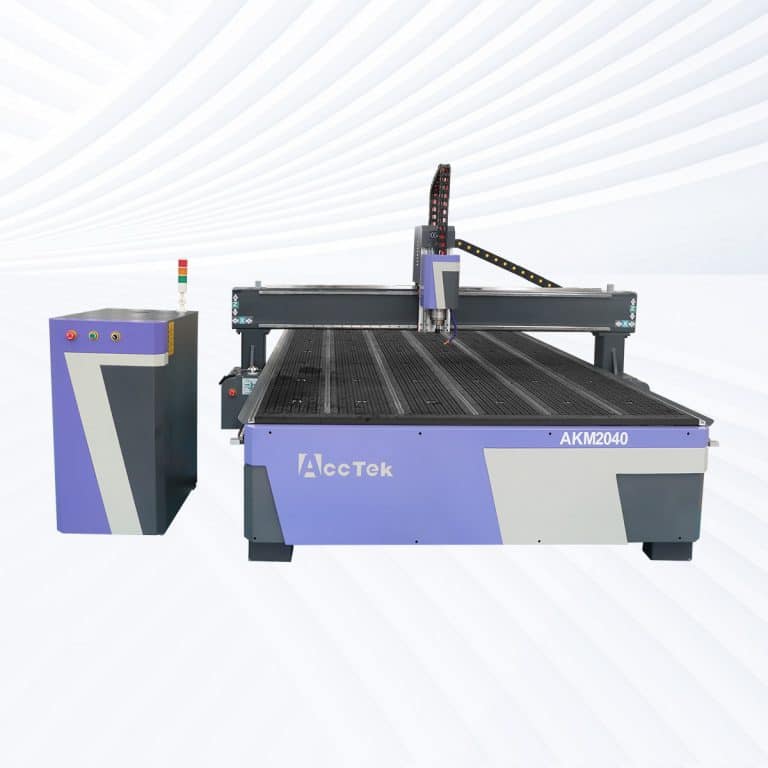

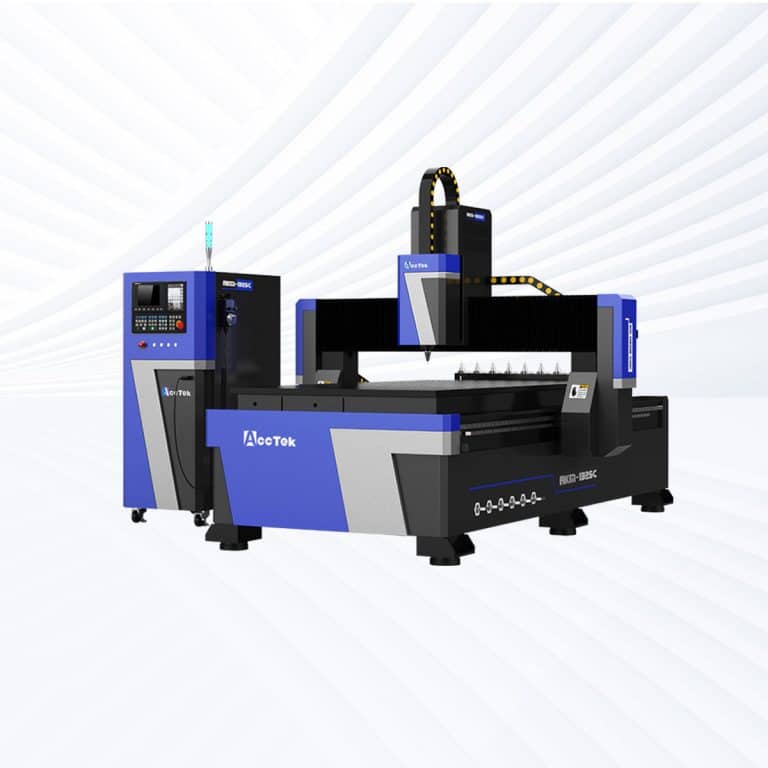

Product Introduction

Types of Plastic CNC Routers

Benefits of CNC Routing Plastic

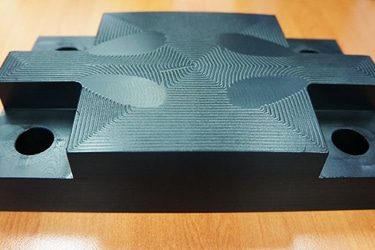

High Precision and Clean Finishes

Plastic CNC routers deliver smooth, burr-free edges and exact dimensions on every cut. This eliminates the need for extensive post-processing, ensuring professional-quality results and reducing waste from errors, even with intricate shapes or delicate plastic components.

Versatility Across Plastic Types

From acrylic and polycarbonate to PVC, HDPE, and ABS, CNC routers handle a wide variety of plastic materials. This versatility allows businesses to expand product offerings and confidently tackle projects across signage, packaging, automotive, and industrial sectors.

Efficient Production Speed

Automated cutting and routing greatly reduce production time compared to manual processing. Complex shapes and detailed engravings can be completed quickly, enabling businesses to scale operations, meet deadlines, and increase overall productivity without compromising quality.

Consistent Repeatability

CNC technology ensures identical results every time. Once a design file is created, it can be replicated endlessly with no variation, making plastic CNC routers ideal for batch production, prototyping, and maintaining strict product uniformity.

Reduced Material Waste

Optimized toolpaths minimize cutting errors and maximize material use. This translates into lower production costs, less waste, and more sustainable operations—particularly important when working with high-value plastics like acrylic or polycarbonate.

Easy Customization and Flexibility

Design changes can be implemented quickly through software, allowing for rapid prototyping or one-off custom parts. CNC routers adapt easily to new designs, giving businesses the flexibility to respond to customer needs and market trends.

Compatible Plastic Materials

- Acrylic

- ABS

- PC

- Rigid PVC

- Foam Board PVC

- HDPE

- LDPE

- PP

- PET

- PETG

- HIPS

- Standard Polystyrene

- Nylon

- PTFE

- PEEK

- Polyurethane (PU) Sheets

- Expanded PVC

- Acrylic Mirror Sheets

- Cast Acrylic

- Extruded Acrylic

- CPVC

- G10/FR4

- Phenolic Laminates

- UHMW

- Delrin

- Melamine Board

- Coroplast

- ABS/PC Blends

- Polyimide Sheets

- EVA Foam Sheets

- PMMA Light Diffuser Panels

- Bakelite Sheets

- ABS Foam Board

- ASA

- Expanded Polystyrene Sheets

- Polycarbonate Twin-Wall Sheets

- Foamed Polyethylene Sheets

- Polyester Sheets

- Polybutylene Terephthalate

- Polyvinyl Butyral

Application of Plastic CNC Routers

Customer Testimonials

Comparison VS Other Engraving Technologies

| Feature | Plastic CNC Router | Laser Engraving | Hand Engraving | Chemical Etching |

|---|---|---|---|---|

| Cutting Depth | Deep and variable (2D & 3D) | Shallow, surface-level only | Variable, depends on skill | Limited, usually surface |

| Precision | High, computer-controlled accuracy | Extremely fine for surface detail | Inconsistent, depends on craftsman | Moderate, depends on masking process |

| Speed | Fast for complex designs & production | Very fast for surface work | Slow and labor-intensive | Moderate, requires multiple steps |

| Material Compatibility | Works on most plastics (acrylic, ABS, PVC, PC, HDPE, etc.) | Limited; some plastics discolor or melt | Any workable plastic | Limited, some plastics resist etching |

| Complex Designs | Handles intricate 2D/3D patterns | Excellent for 2D detailing | Limited by hand skill | Good for fine 2D patterns |

| Repeatability | Perfectly repeatable via digital files | High, repeatable designs | Difficult to replicate consistently | High, once masks are prepared |

| Setup Requirements | Requires CAD/CAM software & tooling | Design software, laser calibration | No software, but requires skill & tools | Masking, chemicals, and safety setup |

| Learning Curve | Moderate, training needed | Moderate, software-based | Very steep, years of practice | Moderate, process-sensitive |

| Production Volume | Ideal for small or large-scale production | Great for medium runs & surface marking | Poor, suited for one-off pieces | Good for batch processing |

| Surface Finish | Clean cuts, smooth edges, no burning | Burn marks or melting possible | Textured, handmade look | Matte finish, less crisp |

| Durability of Work | Structural carvings & long-lasting cuts | Surface-only, may fade or wear | Durable but inconsistent | Shallow marks, prone to wear |

| Customization | Quick digital design changes | Easy digital adjustments | Manual, slow changes | Slower to adjust designs |

| Waste & Safety | Minimal waste, safe with dust collection | Minimal waste, risk of fumes | No waste, but labor-intensive | Hazardous chemicals, disposal needed |

| Cost Efficiency | Higher initial cost, low per-part cost | Moderate cost, low per-part cost | Low equipment cost, high labor | Low equipment cost, high consumable cost |

| Best Use Case | Prototyping, production, signage, industrial parts | Fine logos, barcodes, shallow detail | Artistic, unique handmade pieces | Industrial marking, serial coding |

Why Choose Us

High Precision & Efficiency

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Robust and Durable Design

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Intelligent Control Systems

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

Flexible Customization

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

Related Resources

What Is The Accuracy Of CNC Routers

This article is a comprehensive guide that explains the precision of CNC routers, the key factors affecting precision, expected performance, and how to improve machining results.

How to Choose the Right Router Bits for CNC Routers

This article explains how to select the right router bit for your CNC router, including cutter type, material, coating, and tip, to achieve precise, efficient, and durable cutting performance.

Stepper Motor VS Servo Motor

This article compares stepper motors and servo motors, detailing their working principles, performance characteristics, applications, and key differences in modern automation.

How to Choose the Right CNC Router Spindle

This article explains how to choose the right CNC router spindle by detailing key factors such as power, torque, speed range, cooling type, precision, and machine compatibility.

Frequently Asked Questions

How Much Do Plastic CNC Routers Cost?

- 3-Axis CNC Routers: $3,000 – $10,000. These are the most affordable plastic CNC routers, offering cutting, drilling, and engraving along the X, Y, and Z axes. They’re widely used for acrylic signs, plastic sheets, and basic components. While budget-friendly, they have limits when handling complex geometries or 3D machining.

- 4-Axis CNC Routers: $12,000 – $22,000. Adding a rotary axis, 4-axis CNC routers can carve and machine cylindrical or curved plastic components. This makes them useful for more advanced signage, prototyping, or decorative elements. The higher price reflects added precision and flexibility compared to 3-axis models.

- 5-Axis CNC Routers: $57,000 – $70,000. At the industrial level, 5-axis CNC routers can machine plastic parts from nearly any angle, making them ideal for automotive, aerospace, and complex mold-making applications. Their cost reflects advanced engineering, high spindle speeds, and the ability to produce precise, intricate shapes without multiple setups.

- ATC (Automatic Tool Changer) CNC Routers: $8,000 – $25,000. ATC CNC routers are priced according to size, spindle power, and automation level rather than axis count. These machines automatically switch between cutting tools, improving efficiency when machining different plastic types or performing multiple operations in a single job. They’re especially valuable for production facilities where time savings translate into higher output.

Is The Spindle Of Plastic CNC Routers Air Or Water-Cooled?

- Air-Cooled Spindles: Air-cooled spindles rely on built-in fans to dissipate heat. They are simpler to set up, requiring no external water pumps, tanks, or hoses. Air-cooled designs are common in entry-level and mid-range CNC routers, offering decent cooling for moderate workloads. However, they can be noisier than water-cooled spindles and may run hotter under heavy, continuous operation.

- Water-Cooled Spindles: Water-cooled spindles circulate coolant through a closed loop system, using pumps and reservoirs to maintain low operating temperatures. This makes them quieter, more stable, and more durable under long working hours. They are especially popular in professional or industrial CNC routers that cut plastics at high speeds, where overheating can damage both the spindle and the workpiece. The trade-off is added complexity, as water cooling requires setup, monitoring, and occasional maintenance of the cooling system.

- Customization Based on Customer Requirements: We allow customers to choose between air or water cooling, depending on their production needs. Shops prioritizing simplicity and lower costs often select air cooling, while those requiring high precision, continuous use, or quieter operation typically opt for water cooling.

How Should I Choose Plastic CNC Routers?

- CNC Router Type and Number of Axes: A 3-axis CNC router is sufficient for cutting and engraving flat plastic sheets, such as acrylic signs or panels. A 4-axis CNC router adds rotary machining for cylindrical or curved parts, while 5-axis machines allow complex geometries and mold-making with high precision. The choice should reflect the complexity of the projects being undertaken.

- Spindle Power and Cooling: The spindle determines cutting speed and efficiency. For plastics like acrylic or polycarbonate, higher spindle speeds with stable cooling (air or water) ensure clean cuts without melting edges. Water-cooled spindles provide quieter operation and longer life, while air-cooled options are simpler and lower in cost.

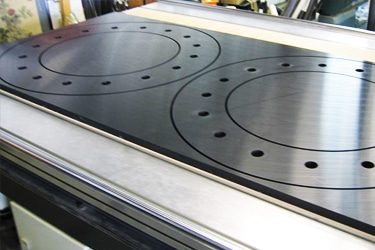

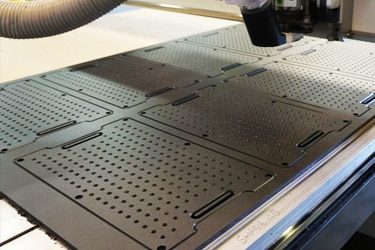

- Work Area Size and Table Type: The machine’s bed size should match the dimensions of the plastic sheets being processed. Vacuum tables are particularly useful for holding thin or flexible materials firmly in place, preventing warping or shifting during cutting. For small-scale projects, clamps or fixtures may be sufficient.

- Precision and Control System: Accuracy is critical when machining plastics, especially for parts that require smooth edges or tight tolerances. Look for CNC routers with rigid frames, servo motors, and reliable control systems. Compatibility with advanced CAD/CAM software also ensures smoother workflows.

- Automatic Tool Changing (ATC): If projects require frequent switching between cutting, drilling, and engraving bits, an ATC system saves time and reduces manual intervention. This is especially valuable in production environments where efficiency and consistency matter.

- Dust and Chip Extraction: Plastic machining generates chips and fine particles that can interfere with precision and cause overheating. A good dust collection or vacuum extraction system is essential for keeping the work area clean and protecting both the machine and operator.

- Budget and Support: Costs range from $3,000 for entry-level 3-axis CNC routers to over $70,000 for industrial 5-axis machines. Beyond the initial purchase, consider the availability of spare parts, after-sales service, training, and warranty. Reliable support ensures long-term productivity.

What Are The Risks Of CNC Routing Plastics?

- Melting and Heat Build-Up: Plastics like acrylic or polycarbonate can melt when router bits generate excessive heat. This not only ruins edge quality but can also cause material to fuse onto the bit, leading to tool breakage or machine strain. Proper feeds, speeds, and cooling (air blast or misting) are key to preventing overheating.

- Dust and Chip Accumulation: Machining plastics produces fine chips and dust that can cling to surfaces due to static electricity. Without proper dust collection, this buildup affects accuracy, increases fire hazards, and creates breathing risks for operators.

- Toxic Fumes and Chemical Exposure: Certain plastics release harmful fumes when cut. For example, cutting PVC produces toxic chlorine gas, while some composites may emit formaldehyde or other hazardous compounds. Adequate ventilation, fume extraction, and material verification are essential for safe operation.

- Cracking and Chipping: Brittle plastics, such as acrylic, are prone to cracking or edge chipping under aggressive cutting speeds or improper tooling. This can waste material and create sharp, hazardous fragments. Specialized bits and proper machining parameters reduce the risk.

- Fire Hazards: Although plastics don’t ignite as easily as wood dust, accumulated chips and heat from dull tools can create fire risks. Continuous supervision, dust extraction, and sharp tooling help minimize this danger.

- Tool Wear and Breakage: Plastics vary in hardness and abrasiveness, and cutting them at improper settings can rapidly dull router bits. In some cases, bits may snap under stress, posing risks to both the machine and operator. Regular inspection and replacement of tools is necessary.

- Material-Specific Limitations: Not all plastics are safe or practical to machine with CNC routers. While acrylic, ABS, and acetal are common choices, PVC and certain composites should be avoided due to toxic byproducts. Knowing material properties beforehand ensures safe, high-quality results.

What Are The Environmental Requirements For Using Plastic CNC Routers?

- Ventilation and Air Quality: Routing plastics generates chips, dust, and, in some cases, fumes. A well-ventilated workspace with air extraction systems is essential to prevent the buildup of airborne particles and harmful gases. For materials that release toxic fumes (such as ABS or composites), additional fume filtration or exhaust systems should be installed.

- Dust and Chip Collection: Plastic machining produces lightweight chips that cling to surfaces due to static electricity. A high-quality dust collector or vacuum extraction system prevents chips from interfering with accuracy, reduces fire risks, and maintains a clean workspace.

- Temperature Control: Stable room temperatures help maintain both machine accuracy and material integrity. Excessive heat can cause plastics to soften or warp, while extreme cold may make them brittle and prone to cracking. Climate-controlled workshops ensure consistent machining results.

- Humidity Control: Unlike wood, plastics are less sensitive to moisture, but high humidity can still affect static buildup and machine electronics. Keeping humidity within moderate levels helps protect both the CNC router’s electrical components and the operator’s safety.

- Electrical Stability: CNC routers require a steady electrical supply for spindles, motors, and control systems. Voltage fluctuations or surges can cause malfunctions or damage sensitive electronics. Surge protectors or uninterruptible power supplies (UPS) are recommended for stable operation.

- Workspace Safety and Layout: CNC routers should be installed in a clean, uncluttered area with sufficient clearance for loading and unloading large plastic sheets. Safety zones and easy access to emergency stop controls reduce the risks of accidents. Fire extinguishers and first-aid kits should also be readily available.

- Noise Management: Plastic CNC routers generate significant noise during high-speed cutting. Acoustic enclosures, noise barriers, or hearing protection help maintain a safer, more comfortable working environment, especially in shared spaces.

- Cooling and Lubrication Systems: For machines equipped with water-cooled spindles, proper coolant reservoirs and circulation systems are required. Cooling prevents overheating and extends spindle life. If mist or air blast systems are used, good air filtration ensures that fine particles don’t accumulate in the workshop.

What Problems Can Be Encountered When CNC Routing Plastics?

- Melting and Poor Edge Quality: Plastics like acrylic and polycarbonate are prone to melting when cut at improper feed rates or spindle speeds. This leads to rough edges, fused chips on the bit, and a cloudy finish instead of the desired polished edge. Using sharp tools, higher feed rates, and cooling systems helps reduce this issue.

- Chip Welding and Tool Clogging: Heat buildup can cause plastic chips to melt and stick to the cutting bit, a process called “chip welding.” This clogs the tool, increases friction, and risks damaging both the bit and the workpiece. Proper chip evacuation with air blast or vacuum extraction is critical.

- Cracking and Chipping: Brittle plastics, especially acrylic, can crack or chip under aggressive cutting forces. This is common at edges, corners, or when drilling holes. Specialized plastic-cutting bits and gradual cutting passes minimize the risk.

- Static Electricity and Dust Buildup: Plastic machining generates static, which causes chips and fine particles to cling to surfaces, the machine, and even operators. This can interfere with accuracy, affect finishes, and pose safety concerns. Anti-static systems and effective dust extraction help manage this problem.

- Dimensional Inaccuracy: Plastics expand or contract with temperature changes during cutting. Heat from the spindle may distort thin sheets or cause slight warping, leading to parts being out of tolerance. Controlled feeds, cooling, and stable environmental conditions improve consistency.

- Tool Wear and Breakage: While plastics are softer than metals, some engineering plastics (like acetal or fiberglass-reinforced composites) are abrasive and can dull tools quickly. Using high-quality bits designed for plastics extends tool life and reduces breakage.

- Surface Scratching and Finish Problems: Soft plastics scratch easily during machining or when chips rub against the surface. Improper clamping, poor vacuum hold-down, or dull tools can also leave visible marks. Protective films on plastic sheets and smooth finishing passes help maintain surface quality.

- Material Limitations: Not all plastics are suitable for CNC routing. For example, PVC should never be cut due to toxic chlorine gas emissions. Other composites may produce hazardous fumes or dust. Always confirm material compatibility before machining.

What Training Is Required To Operate Plastic CNC Routers?

- Basic CNC Operation and Controls: Operators need to understand how to start, stop, and control the CNC router safely. This includes powering up systems, homing axes, loading files, setting zero points, and executing jobs. Training ensures operators can respond quickly to errors or emergencies.

- CAD and CAM Software Skills: CNC routers rely on CAD (Computer-Aided Design) for creating part drawings and CAM (Computer-Aided Manufacturing) for generating toolpaths. Training includes designing plastic parts, selecting the right cutting strategies, and exporting machine-ready G-code.

- Tool Selection and Setup: Choosing the correct router bits is critical for cutting plastics cleanly. Operators must be trained to identify which tools work best for acrylic, ABS, acetal, and other plastics, as well as how to install, secure, and inspect tooling before use.

- Feeds, Speeds, and Machining Parameters: Plastics require specific cutting speeds and feed rates to avoid melting, chipping, or tool wear. Training covers how to calculate and adjust these parameters based on plastic type, thickness, and bit design.

- Workholding and Material Setup: Proper clamping, fixturing, or vacuum table use ensures plastics don’t shift or vibrate during cutting. Operators must learn how to secure thin sheets without warping and how to prepare larger panels for precise machining.

- Dust Collection and Safety Systems: Plastic CNC routers produce chips, dust, and sometimes fumes. Training emphasizes proper use of dust extraction, static control, ventilation, and personal protective equipment (PPE) such as masks, safety glasses, and hearing protection.

- Maintenance and Troubleshooting: Operators must learn routine maintenance, including cleaning, lubrication, spindle checks, and bit replacement. Training also covers troubleshooting common issues like melting edges, tool clogging, or calibration errors.

- Material Knowledge and Safety Awareness: Not all plastics are safe to route. Training includes identifying safe materials (acrylic, ABS, acetal, polyethylene) versus unsafe ones (PVC, chlorine-based plastics) and understanding chemical hazards. Operators must be prepared to handle materials responsibly.

What PPE Do Operators Need When CNC Routing Plastics?

- Eye Protection: Safety glasses or full-face shields are mandatory, as high-speed router bits can eject small plastic chips at dangerous velocities. Clear, impact-resistant eyewear prevents injuries and ensures operators can monitor the cutting process without obstruction.

- Respiratory Protection: Cutting plastics produces fine dust and, with some materials, hazardous fumes. A dust mask or respirator rated for fine particles (N95 or higher) is recommended. For plastics like ABS or composites that release chemical vapors, a respirator with activated carbon filters provides additional protection.

- Hearing Protection: Plastic CNC routers operate at high spindle speeds and generate loud noise, especially in combination with dust extraction systems. Earplugs or earmuff-style hearing protection prevent long-term hearing damage.

- Hand Protection: Gloves should be used carefully. While they protect against sharp plastic edges and handling large sheets, loose-fitting gloves must never be worn near rotating spindles. Cut-resistant, snug-fitting gloves are recommended for material handling, but should be removed when the machine is running.

- Protective Clothing: Operators should wear fitted work clothing without loose sleeves, ties, or jewelry that could get caught in moving parts. Aprons or lab coats made of durable material protect against scratches and chips.

- Foot Protection: Steel-toe or reinforced safety shoes prevent injuries from dropped sheets of acrylic, polycarbonate, or other heavy plastic panels. Non-slip soles are also useful in workshops where dust or chips accumulate on the floor.

- Anti-Static Protection (Optional): Since plastic machining often generates static electricity, grounding straps or anti-static clothing can help reduce buildup, especially when working with thin sheets that attract chips and dust.