Product Introduction

Types of Metal CNC Routers

Benefits of CNC Routing Metal

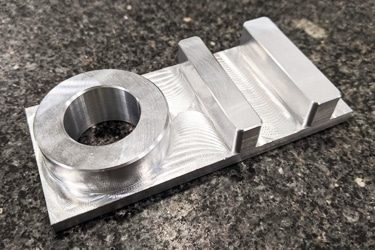

High Precision and Accuracy

Metal CNC routers ensure exact cuts, engravings, and drilling, even on dense or complex alloys. Advanced motion control and rigid structures minimize errors, making them ideal for industries that demand consistent, high-tolerance results on both prototypes and production parts.

Versatility Across Metal Types

From aluminum and brass to stainless steel, copper, titanium, and specialty alloys, CNC routers can process a wide variety of metals. This versatility allows manufacturers to diversify applications, from signage and decorative panels to aerospace and automotive components.

Increased Productivity

Automation speeds up cutting and engraving processes, completing intricate jobs much faster than manual methods. This efficiency helps manufacturers scale operations, meet tight deadlines, and reduce production costs while maintaining consistently high quality across all parts.

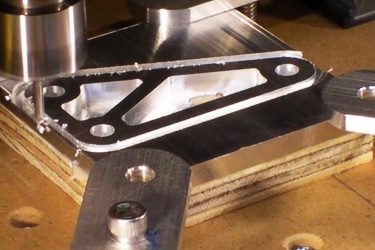

Consistency and Repeatability

Once a digital file is programmed, CNC routers can reproduce designs flawlessly across multiple workpieces. This repeatability is critical for batch production, ensuring uniformity and reliability in everything from industrial components to custom-fabricated metal products.

Reduced Material Waste

Optimized toolpaths and precision cutting maximize sheet utilization and minimize offcuts. This efficiency lowers material costs, reduces scrap, and contributes to more sustainable manufacturing practices—especially when working with high-value metals such as titanium or stainless steel.

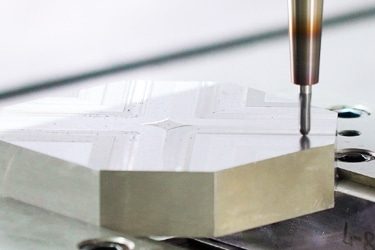

Expanded Design Capabilities

Metal CNC routers enable the creation of complex shapes, fine engravings, and detailed patterns that are difficult or impossible to achieve manually. This flexibility supports innovation in product design, prototyping, and custom manufacturing across multiple industries.

Compatible Metal Materials

- Aluminum

- Aluminum 1100

- Aluminum 2024

- Aluminum 5052

- Aluminum 6061

- Aluminum 7075

- Anodized Aluminum

- Cast Aluminum

- Aluminum Composite Panels (ACP)

- Brass

- Yellow Brass

- Red Brass

- Naval Brass

- Cartridge Brass

- Bronze

- Phosphor Bronze

- Silicon Bronze

- White Bronze

- Beryllium Copper

- Pure Copper

- Oxygen-Free Copper

- Electrolytic Tough Pitch Copper

- Tellurium Copper

- Tin

- Pure Zinc

- Zinc Alloys

- Lead

- Pewter

- Britannia Metal

- Magnesium

- Magnesium Alloys

- Nickel Silver

- Soft Nickel Alloys

- Cadmium

- Indium

- Gallium

- Thallium

- Alkali Metals

- Alkaline Earth Metals

- Decorative Metal Composites

Application of Metal CNC Routers

Customer Testimonials

Comparison VS Other Engraving Technologies

| Feature | Metal CNC Router | Laser Engraving | Hand Engraving | Chemical Etching |

|---|---|---|---|---|

| Cutting Depth | Deep, variable 2D & 3D cuts | Shallow, surface engraving only | Variable, depends on artisan skill | Very shallow, surface-only |

| Precision | High accuracy, tight tolerances | Extremely fine surface detail | Inconsistent, artisan-dependent | Moderate, depends on masking quality |

| Speed | Fast for cutting & engraving | Very fast for surface marking | Slow, labor-intensive | Moderate, multi-step process |

| Material Compatibility | Wide: aluminum, brass, copper, alloys, mild steel | Limited, struggles with reflective metals | Any soft metal, but slow | Limited to thin, flat metals |

| Complex Designs | Handles intricate 2D/3D geometries | Excellent for detailed 2D marks | Limited to hand skill | Restricted to stencil/mask designs |

| Repeatability | Perfect digital repeatability | Repeatable for surface-only | Hard to replicate consistently | Repeatable if masks are identical |

| Setup Requirements | CAD/CAM software, tooling, coolant | Design software, laser setup | Tools and artisan training | Chemical baths, masking, safety |

| Learning Curve | Moderate, requires training | Moderate, software-driven | Very steep, years of practice | Moderate, process-sensitive |

| Production Volume | Ideal for prototypes & mass production | Good for medium runs, surface only | Poor, suited for one-offs | Good for batch runs, not 3D |

| Surface Finish | Smooth, clean edges | Burn marks, discoloration possible | Handmade texture | Matte, less sharp detail |

| Durability of Work | Long-lasting, structural cuts | Surface-only, may fade/wear | Durable but inconsistent | Shallow, not durable |

| Customization | Quick design edits via CAD | Easy file changes | Manual, slow, less flexible | Requires new masks each design |

| Waste & Safety | Minimal waste, safe with coolant systems | Minimal waste, harmful fumes possible | No waste, but laborious | Hazardous chemicals & disposal issues |

| Cost Efficiency | Higher upfront, low per-part | Moderate setup, limited use | Low tools, high labor cost | Low equipment, high chemical cost |

| Best Use Case | Prototypes, parts, signage, industrial metalwork | Logos, barcodes, shallow detail | Artistic, unique handmade pieces | Industrial coding, flat markings |

Why Choose Us

High Precision & Efficiency

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Robust and Durable Design

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Intelligent Control Systems

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

Flexible Customization

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

Related Resources

What Is The Accuracy Of CNC Routers

This article is a comprehensive guide that explains the precision of CNC routers, the key factors affecting precision, expected performance, and how to improve machining results.

How to Choose the Right Router Bits for CNC Routers

This article explains how to select the right router bit for your CNC router, including cutter type, material, coating, and tip, to achieve precise, efficient, and durable cutting performance.

Stepper Motor VS Servo Motor

This article compares stepper motors and servo motors, detailing their working principles, performance characteristics, applications, and key differences in modern automation.

How to Choose the Right CNC Router Spindle

This article explains how to choose the right CNC router spindle by detailing key factors such as power, torque, speed range, cooling type, precision, and machine compatibility.

Frequently Asked Questions

How Much Do Metal CNC Routers Cost?

- Standard Metal CNC Routers: Standard models are priced between $4,000 and $4,500. These machines are well-suited for light to medium-duty metalworking tasks such as cutting aluminum sheets, engraving patterns, or fabricating small metal parts. They are popular with small workshops, sign makers, and entry-level manufacturers due to their affordability and ease of use.

- Heavy-Duty Metal CNC Routers: For more demanding industrial applications, heavy-duty models cost around $6,000 to $7,500. These CNC routers are built with reinforced structures, stronger spindles, and more powerful motors, enabling them to cut tougher metals with higher accuracy and longer durability. They are commonly used in fabrication shops, automotive prototyping, and industries that require continuous operation.

- ATC (Automatic Tool Change) Metal CNC Routers: High-efficiency models with automatic tool change capabilities are priced between $12,000 and $13,000. These machines are designed for professional environments where multiple tools are required for milling, drilling, and engraving in a single production cycle. The ATC function reduces downtime, improves productivity, and makes them ideal for large-scale production in aerospace, mold-making, and precision engineering.

What Are The Disadvantages Of Metal CNC Routers?

- High Initial Investment: Metal CNC routers are generally more expensive than wood, plastic, or foam CNC routers due to their reinforced build, heavy-duty spindles, and advanced components. Even entry-level models require a significant investment, while industrial-grade machines with automatic tool changers are costlier, making them less accessible to hobbyists or small shops.

- Maintenance and Operating Costs: These machines require regular maintenance, such as lubrication of moving parts, replacement of cutting tools, and calibration to maintain precision. Cutting metals also wears down tools more quickly compared to softer materials, leading to higher consumable costs over time.

- Complex Setup and Training: Operating a metal CNC router demands greater technical expertise than routing softer materials. Operators must understand feeds and speeds, tool paths, and material properties to avoid tool breakage or poor-quality cuts. This often requires additional training and skilled labor.

- Slower Cutting Speeds: Metals are harder and denser than other materials, which means machining times are longer. High precision comes at the cost of slower operations, and production runs may take significantly more time compared to working with wood, plastics, or composites.

- Power and Space Requirements: Heavy-duty CNC routers for metal often require higher electrical power and a stable shop environment. They are also larger and heavier, meaning they need more space and a strong foundation for installation.

- Noise and Safety Concerns: Cutting metals generates high noise levels, heat, and sharp chips, which can pose safety risks if not managed with proper PPE (Personal Protective Equipment) and dust/chip extraction systems. Inadequate handling may lead to injuries or equipment damage.

Is CNC Routing Metal Safe?

- Flying Chips and Sharp Edges: CNC cutting of metals such as aluminum, brass, steel, or copper produces sharp chips and burrs that can become airborne. These fragments pose risks of eye injuries or skin cuts if proper protective eyewear and guards are not used.

- Heat and Fire Risk: Metal machining generates significant friction and heat. Without proper cooling (air or liquid), excessive heat can damage tools, warp materials, or, in rare cases, ignite flammable debris in the work area. Consistent coolant application and fire prevention measures are critical.

- Tool Breakage: Metal CNC routing places high stress on cutting tools. Dull or improperly selected bits can break under pressure, sending fragments flying at high speed. This is why using the correct tooling, feeds, and speeds is essential for safe operation.

- Noise and Vibration: Machining metal produces high noise levels and machine vibration, which can be harmful if not properly managed. Operators should wear hearing protection, and machines should be securely installed on solid foundations to reduce vibration risks.

- Electrical and Power Considerations: Metal CNC routers often require more powerful motors and spindles than wood or plastic CNC routers, meaning higher voltage and current loads. Improper electrical setups can cause hazards, so professional installation and grounding are necessary.

- Dust, Fumes, and Lubricants: Unlike wood or plastic dust, metal machining generates fine particles and fumes when coolants or cutting fluids are used. These can irritate the respiratory system or create slippery work surfaces. Effective extraction systems and ventilation are essential for safety.

What Problems Can Be Encountered When Using CNC Routing Metal?

- Tool Wear and Breakage: Metals such as stainless steel or titanium are extremely tough and abrasive. Cutting tools dull quickly, and in some cases, they may snap under pressure if feeds, speeds, or tool choices are not optimized. Regular tool inspection and replacement are required to maintain efficiency.

- Heat Buildup: Routing metals produces significant friction, which generates heat. Excessive heat can damage tools, warp thin metal sheets, or cause poor edge finishes. This problem is usually managed with cooling methods such as mist lubrication or flood coolant, but inadequate cooling remains a common issue.

- Chatter and Vibration: Metals are rigid and require precise cutting conditions. If the machine setup is not stable or the cutting parameters are incorrect, chatter (vibration marks on the surface) may occur, resulting in poor finish quality and potential tool damage.

- Chip Removal Issues: Unlike wood or plastics, metal produces dense and sharp chips. If these are not effectively cleared from the cutting area, they can cause tool re-cutting, surface scratching, or machine jams. Strong vacuum systems or chip conveyors are often needed.

- Machine Stress and Maintenance Needs: Metals put more strain on spindles, motors, and drives compared to softer materials. Machines not designed for heavy-duty cutting may overheat, lose accuracy, or suffer premature wear, leading to higher maintenance costs.

- Surface Finish Problems: Incorrect cutting speeds, dull tools, or poor coolant management can lead to burrs, rough edges, or tool marks. Achieving a clean finish in harder metals requires precision settings and high-quality tooling.

- Noise and Safety Concerns: Machining metals is much noisier than working with wood, foam, or plastics. High noise levels and the danger of flying chips make proper PPE and machine enclosures essential for safe operation.

- Material-Specific Challenges: Each type of metal presents unique difficulties. Aluminum may clog tools if lubrication is poor, stainless steel is prone to work hardening, and copper alloys can cause excessive tool wear. Choosing the correct tooling and strategies for each metal is critical.

How Do I Purchase Metal CNC Routers?

- Material Compatibility: Ensure the CNC router can cut the specific metals you plan to work with (aluminum, steel, brass, copper, titanium, etc.), as each has different hardness and machining requirements.

- Machine Power and Rigidity: Metal cutting requires robust frames, high spindle power, and durable motors. A weaker machine may flex under load, leading to poor accuracy and faster tool wear.

- Cooling and Lubrication Systems: Metals generate significant heat during routing, so machines equipped with mist or flood coolant systems are essential for safe and efficient operation.

- Software and Control Systems: Verify compatibility with CAD/CAM software for ease of programming and workflow integration. Advanced controllers support more complex toolpaths for precise metal machining.

- Support and Warranty: Purchase from reputable suppliers that provide after-sales service, training, spare parts, and technical support to minimize downtime.

How Do I Maintain Metal CNC Routers?

- Daily Maintenance:

- Cleaning Work Area: Metal chips and dust can interfere with moving parts. After each use, clean the worktable, spindle, and surrounding area using a vacuum or compressed air.

- Lubrication Check: Inspect and lubricate guide rails, ball screws, and bearings to ensure smooth motion and reduce wear. Many machines feature automatic lubrication systems—verify oil levels daily.

- Cooling System Monitoring: For CNC routers with mist or flood coolant systems, check coolant levels, cleanliness, and flow to avoid overheating during metal cutting.

- Weekly Maintenance:

- Inspect Spindle and Collets: Metal machining exerts high forces on the spindle and tool holders. Check for wear, debris, and tightness to ensure accurate tool positioning.

- Check Drive Belts and Couplings: Ensure belts and couplings are tight, aligned, and free from cracks or wear, as these directly affect precision and cutting performance.

- Software and Control Systems: Run diagnostics to verify system calibration and correct any offset errors in toolpath execution.

- Monthly Maintenance:

- Electrical System Check: Inspect wiring, connectors, and control panels for signs of wear, overheating, or loose contacts. Metal machining requires stable electrical performance.

- Alignment and Calibration: Check the machine’s axes using calibration tools to ensure accuracy. Misalignment over time can lead to poor-quality cuts and wasted material.

- Air Supply Inspection: For CNC routers using pneumatic tool changers or dust extraction, ensure filters, regulators, and hoses are free from blockages.

- Annual Maintenance:

- Deep Cleaning and Overhaul: Perform a full inspection of the spindle, motors, linear guides, and bearings. Replace worn components proactively before they cause failure.

- Coolant System Flush: Drain and replace coolant to prevent bacterial growth, clogging, and rust in the system.

- Professional Servicing: Have certified technicians conduct a detailed inspection to maintain warranty compliance and machine integrity.

What PPE Do Operators Need When Using Metal CNC Routers?

- Eye and Face Protection:

- Safety glasses with side shields are mandatory to protect against flying metal chips and dust.

- A full-face shield may be required during heavy cutting or when coolant spray is used, offering additional coverage against splashing fluids and fine debris.

- Hearing Protection:

- CNC routing of metals produces significant noise, often above safe levels. Earplugs or earmuffs should be worn to prevent long-term hearing damage, especially in high-production environments.

- Respiratory Protection:

- Depending on the metal being machined, fine dust and fumes can be produced (for example, when cutting aluminum or stainless steel).

- A dust mask or respirator is recommended, particularly when ventilation or dust extraction systems are not sufficient to maintain safe air quality.

- Hand Protection:

- Operators should wear cut-resistant gloves when handling raw materials, sharp-edged parts, or tools.

- However, gloves must not be worn during machine operation, as they can become entangled in moving parts—gloves are only for setup, loading, and unloading.

- Body Protection:

- Operators should wear fitted clothing without loose sleeves or accessories to avoid entanglement.

- Heavy-duty workwear, such as long-sleeve shirts and trousers, is preferred to protect skin from hot chips and sharp edges.

- Aprons or protective jackets made of durable material may be used in heavy-duty applications.

- Foot Protection:

- Steel-toe safety shoes are recommended to prevent injuries from dropped tools, heavy materials, or machine components.

- Slip-resistant soles are important for working around coolant spills or metal shavings that make floors slick.

What Is The Life Expectancy Of Metal CNC Routers?

- Standard Metal CNC Routers: These machines, often used for light to medium-duty cutting of aluminum, brass, and softer metals, typically last 8–12 years with regular use. Proper lubrication, alignment checks, and part replacements can extend their usable life significantly.

- Heavy-Duty Metal CNC Routers: Designed for demanding applications, such as continuous machining of stainless steel or hardened alloys, heavy-duty CNC routers generally last 12–15 years. Their robust frames, stronger spindles, and higher-grade components allow them to endure longer operating cycles before major rebuilds are required.

- ATC (Automatic Tool Change) Metal CNC Routers: Because these CNC routers include more complex systems, such as tool changers and automatic calibration, their life expectancy is often 10–12 years. While their advanced features improve efficiency, the additional moving parts require careful upkeep to prevent premature wear.

- Factors Affecting Life Expectancy:

- Maintenance: Routine cleaning, lubrication, and part replacement (belts, bearings, spindles) are crucial to avoid breakdowns.

- Operating Conditions: CNC routers in clean, temperature-controlled workshops last longer than those exposed to dust, heat, or poor ventilation.

- Material Type: Cutting softer metals like aluminum produces less wear compared to machining hardened steels, which can shorten spindle and tool life.

- Usage Intensity: Machines used for high-volume production will wear faster than those used occasionally in prototyping or small workshops.