Product Introduction

Material Routing Capability

| Material Type | 1.5 kW | 2.2 kW | 3.0 kW | 3.2 kW | 3.5 kW | 4.5 kW | 5.5 kW | 6.0 kW | 7.5 kW | 9.0 kW |

|---|---|---|---|---|---|---|---|---|---|---|

| Softwood | Light Cutting | Standard Cutting | Fast Cutting | Fast Cutting | Fast Cutting | High-Speed Cutting | Heavy-Duty Cutting | Heavy-Duty Cutting | Industrial Cutting | Industrial Cutting |

| Hardwood | Light Duty | Standard Cutting | Stable Cutting | Stable Cutting | High-Precision | Heavy-Duty | Heavy-Duty | High-Torque Cutting | Industrial Cutting | Industrial Cutting |

| Plywood/MDF | Basic Cutting | Smooth Cutting | Fast, Clean Cutting | Fast Cutting | High-Precision | Heavy-Duty | Heavy-Duty | Industrial Smooth Cuts | High-Volume Cutting | High-Volume Cutting |

| HDF/Particle Board/Melamine | Light Cuts | Standard Cuts | Clean Cuts | Clean Cuts | High-Precision | Heavy-Duty | Heavy-Duty | Industrial | Industrial | Industrial |

| Acrylic(PMMA) | Thin Sheets | Clean Cutting | Fast, Clean Edges | High Clarity | High Clarity | Smooth Finishing | Smooth Finishing | Industrial Clarity | Industrial Clarity | Industrial Clarity |

| Polycarbonate/PETG | Thin Sheets | Clean Cutting | Stable Cutting | Stable Cutting | Precision Cutting | Heavy-Duty | Heavy-Duty | Industrial | Industrial | Industrial |

| ABS/PVC Foam Board | Light Duty | Standard | Fast Cutting | Fast Cutting | High Stability | Heavy-Duty | Heavy-Duty | Industrial | Industrial | Industrial |

| HDPE/LDPE/PP/Nylon | Light Cuts | Standard Cuts | Stable Cuts | Stable Cuts | Deep Routing | Heavy-Duty | Heavy-Duty | High-Torque | Industrial | Industrial |

| Delrin/UHMW | Light Duty | Standard | Accurate Routing | Accurate Routing | High-Precision | Heavy-Duty | Heavy-Duty | Industrial | Industrial | Industrial |

| Solid Surface (Corian) | Very Light | Standard | Strong Cutting | Clean Cutting | High-Precision | Heavy-Duty | Heavy-Duty | Industrial Cutting | Industrial Cutting | Industrial Cutting |

| Fiberglass/Carbon Fiber Sheet | Light Trimming | Standard | Precise Routing | Precise Routing | High-Precision | Heavy-Duty | Heavy-Duty | Industrial | Industrial | Industrial |

| Phenolic/Bakelite | Limited | Standard | Clean Routing | Clean Routing | Precision Routing | Heavy-Duty | Heavy-Duty | Industrial | Industrial | Industrial |

| Foam(EVA, XPS, EPS, PU) | Very Easy | Very Easy | Fast Cutting | Fast Cutting | Ultra-Fast | Ultra-Fast | Ultra-Fast | High-Speed | High-Speed | High-Speed |

| Rubber/Leather/Cork | Light Duty | Standard | Clean Edges | Clean Edges | Faster Routing | Heavy-Duty | Heavy-Duty | Industrial | Industrial | Industrial |

| Cardboard/Paperboard | Easy | Easy | Fast Cutting | Fast Cutting | Ultra-Fast | Ultra-Fast | Ultra-Fast | Industrial | Industrial | Industrial |

| ACP/ACM (Surface Routing Only) | Very Light | Standard | Clean Grooves | Clean Grooves | High Precision | Heavy-Duty | Heavy-Duty | Industrial | Industrial | Industrial |

Compatible Materials

- Standard MDF

- High-Density MDF (HDF)

- Ultra-Light MDF

- Moisture-Resistant MDF (MR MDF)

- Fire-Retardant MDF (FR MDF)

- Exterior-Grade MDF

- Veneered MDF

- Melamine-Coated MDF

- Laminated MDF

- Painted MDF Panels

- Primed MDF Sheets

- UV-Coated MDF

- Glossy MDF

- Matte MDF

- Textured MDF

- Embossed MDF

- Shiplap MDF Panels

- Furniture-Grade MDF

- Eco-Friendly MDF (Low Formaldehyde)

- CARB Compliant MDF

- Radiata Pine MDF

- Birch MDF

- Oak MDF

- Walnut MDF

- Bamboo MDF

- Colored MDF (Dyed MDF)

- Black MDF

- White MDF

- Red MDF

- Blue MDF

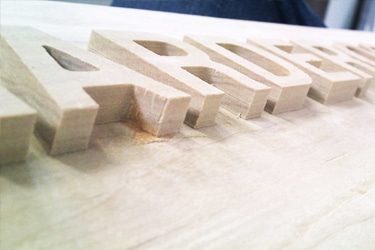

- Decorative Carving MDF

- 3D Wave MDF Panels

- Grooved MDF Panels

- Routed Pattern MDF

- Perforated MDF Panels

- Acoustic MDF Boards

- MDF Moldings

- MDF Beadboard

- Flexible (Bendable) MDF

- MDF Doors & Cabinet Fronts

Application of MDF CNC Routers

Customer Testimonials

Comparison VS Other Engraving Technologies

| Comparison Item | MDF CNC Routing | Laser Engraving | Chemical Etching | EDM Engraving |

|---|---|---|---|---|

| Working Principle | Mechanical cutting with rotating tools | Vaporizing material with laser beam | Chemical reaction removes selected areas | Electrical discharge removes material |

| Material Suitability | MDF, wood, plywood, plastics | Wood, acrylic, coated materials | Metals, glass, ceramics | Conductive metals only |

| Cutting Ability | Full-depth cutting & carving | Mainly engraving; limited cutting | No cutting | No cutting; only erosion |

| Engraving Depth | Deep, moderate, or shallow | Mostly shallow | Very shallow | Deep but slow |

| Accuracy Level | High accuracy for MDF | Very high precision | Moderate accuracy | Extremely high precision |

| Detail Resolution | Good for complex shapes | Excellent fine detail | Limited by masking | Very high resolution |

| Production Speed | Fast for routing & profiling | Fast for engraving | Medium | Slow |

| 3D Capability | Yes, 3D relief carving | Limited 2.5D | No | Limited 2.5D |

| Setup Complexity | Medium (tooling, fixturing) | Low | Medium (chemical prep) | High (electrode setup) |

| Learning Curve | Moderate | Easy–moderate | Moderate | High |

| Operating Costs | Low (bits & electricity) | Low–medium | Medium–high (chemicals) | High (electrodes, wear) |

| Maintenance Needs | Regular lubrication & tool changes | Optics cleaning | Chemical handling & disposal | Electrode wear & dielectric fluid care |

| Safety Concerns | Dust, noise, tool hazards | Laser radiation & fumes | Chemical burns, fumes | Electrical discharge, dielectric fluids |

| Best Applications | MDF cutting, engraving, 3D panels | Fine engraving & marking | Metal textures, patterns | Precision metal machining |

| Ideal Use Case | Furniture panels, décor, signs | Detail-rich 2D designs | Surface marking on metals | High-accuracy metal molds & parts |

Why Choose Us

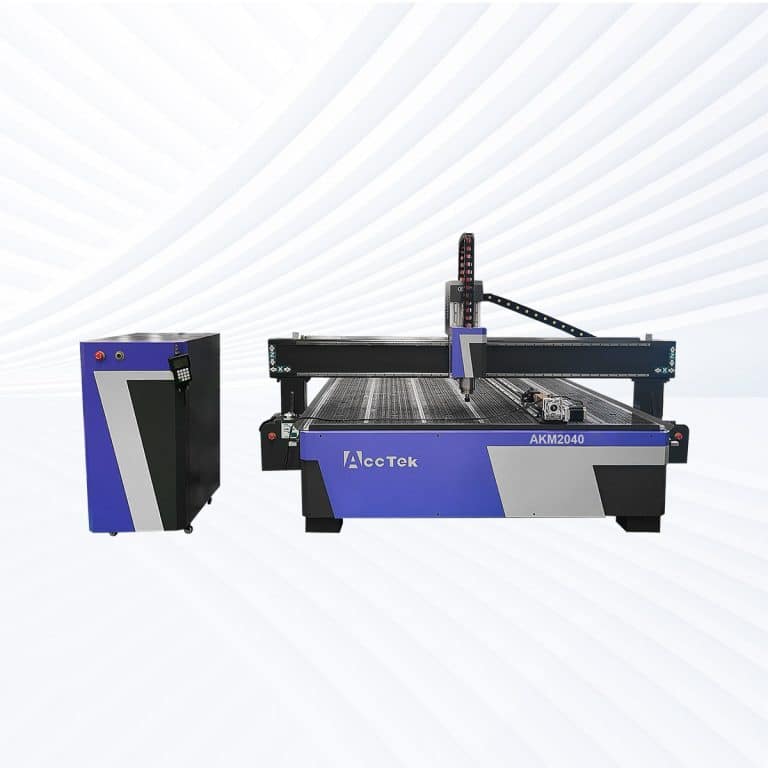

High Precision & Efficiency

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Robust and Durable Design

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Intelligent Control Systems

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

Flexible Customization

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

Related Resources

How Do CNC Routers Work

This article explains the working principle of CNC routers, from the motion system and cutting tools to the software workflow, materials, precision, and actual machining principles.

How To Maintain CNC Routers

This article provides a comprehensive guide on how to maintain CNC routers, covering essential tasks, troubleshooting tips, upgrades, and best practices to ensure optimal performance and longevity.

What Is The Accuracy Of CNC Routers

This article is a comprehensive guide that explains the precision of CNC routers, the key factors affecting precision, expected performance, and how to improve machining results.

How to Choose the Right Router Bits for CNC Routers

This article explains how to select the right router bit for your CNC router, including cutter type, material, coating, and tip, to achieve precise, efficient, and durable cutting performance.

Frequently Asked Questions

What Is The Price Of MDF CNC Routers?

What Is The Working Range Of MDF CNC Routers?

- Small and Medium Working Sizes: Compact models such as 700mm×900mm and 900mm×1500mm are ideal for small woodworking shops, signage production, and custom craft cutting. These machines handle partial birch sheets or smaller components efficiently while requiring minimal floor space.

- Standard Full-Sheet Sizes: Popular configurations like 1300mm×2500mm and 1500mm×3000mm support full 4×8 ft and 5×10 ft birch sheets. These sizes are widely used in furniture manufacturing, cabinetry, and panel processing. They allow complete sheet nesting without pre-cutting, improving workflow efficiency and material utilization.

- Large-Format Industrial Sizes: Larger working ranges, such as 2000mm×3000mm and 2000mm×4000mm, accommodate extra-wide birch panels used in architectural fabrication, interior decoration, or specialty woodworking. These machines provide extended cutting space for oversized layouts, structural components, and long-format designs.

- Extended Length Platforms: Extra-long machines, such as 2000mm×6000mm and 3000mm×6000mm, are suited for industries requiring continuous large-scale birch processing. They are commonly used for stage design, boat building, wall paneling, and prefabrication tasks where seamless long-panel cutting is essential.

- Custom Sizes Upon Request: For specialized workflows, conveyor systems, or unique birch sheet dimensions, custom working ranges can be manufactured. Custom platforms support automation integration, dual-zone vacuum worktables, or multi-head spindle configurations.

What Control System Do MDF CNC Routers use?

- Mach3 Control System: Mach3 is widely used in entry-level and mid-range MDF CNC routers due to its affordability and flexibility. It operates on a PC-based interface and supports standard G-code programming, making it accessible for beginners and small workshops. Mach3 provides reliable motion control for MDF routing, engraving, and panel cutting. While it offers strong performance for general woodworking, it may have limitations in extremely high-speed or heavy industrial workloads.

- Syntec 60W-E Control System: The Syntec 60W-E is a professional-grade CNC controller designed for stable, efficient operation. It features a dedicated control panel, faster processing, and smoother motion control compared to PC-based systems. This controller is well-suited for MDF furniture production, nested-based machining, and continuous operation environments. Its strong communication speed and excellent interpolation capability ensure accurate toolpaths even during complex cuts.

- Syntec 610MA-E5 Control System: The Syntec 610MA-E5 is a high-end industrial CNC control system with advanced functionality. It supports high-speed machining, multi-axis movement, and precise motion stabilization, making it ideal for demanding MDF applications such as intricate 3D carving, deep pocketing, or mass-production panel processing. This controller offers enhanced reliability, large memory capacity, and excellent servo integration, ensuring smooth operation across long production cycles.

What Type Of Worktable Do MDF CNC Routers Use?

- Vacuum Worktable: Vacuum worktables are widely used because they provide strong, even suction across the MDF sheet, holding it securely without mechanical clamps. This is especially useful for large MDF panels or nested-based manufacturing, where multiple components are cut from a full sheet. The vacuum system reduces vibration, prevents shifting, and helps maintain clean, accurate edges. It also speeds up production by eliminating manual clamping and reducing setup time between jobs. Vacuum tables are ideal for high-volume MDF processing and detailed carving, where stability directly affects finish quality.

- T-Slot Worktable: T-slot worktables use mechanical clamps, fixtures, and bolts secured into aluminum slots. They allow flexible positioning of hold-down clamps, making them suitable for irregularly shaped MDF workpieces or smaller components that may not benefit from full-surface suction. T-slot tables also support jig setups, specialty fixtures, and workpieces that require precise positioning. Although setup time may be longer compared to vacuum tables, T-slots offer excellent versatility for custom MDF projects and low-volume production.

- Hybrid Clamping Options: Some MDF CNC routers combine both vacuum zones and T-slot channels, offering enhanced flexibility. This setup allows operators to switch between full-sheet processing and custom clamping as needed, making the CNC router suitable for mixed-application MDF workloads.

What Are The Environmental Requirements For MDF CNC Routers?

- Stable Temperature Conditions: MDF CNC routers perform best in ambient temperatures between 5℃ and 40℃. Keeping the workshop within this range prevents thermal expansion of machine components and avoids overheating of motors, drives, and electronics. Extreme temperature changes can affect cutting precision and MDF material stability.

- Humidity Control: MDF absorbs moisture easily, which can cause swelling, warping, or inconsistent machining depth. Ideal workshop humidity should remain between 30% and 70%, allowing the material and machine to maintain dimensional stability. Dehumidifiers or proper ventilation may be needed in humid climates.

- Effective Dust Extraction: MDF produces extremely fine dust that can clog filters, settle on linear guides, and affect electronics if not managed properly. A high-efficiency dust extraction system is essential to protect machine components, maintain cutting accuracy, and support operator safety. Centralized or dual-port extraction is recommended for larger CNC routers.

- Clean, Debris-Free Environment: Keeping the floor and workspace clean prevents dust buildup around moving parts or electrical systems. Regular cleaning helps reduce airborne particles, protects rails and bearings, and improves overall machine lifespan. Smooth flooring also allows easy movement of MDF sheets.

- Adequate Ventilation: Adequate air circulation helps dissipate heat generated during extended cutting cycles and ensures fresh air flow. While MDF CNC routers do not emit fumes like laser machines, ventilation supports a safer and more comfortable working environment.

- Stable Workshop Floor: A level, rigid concrete floor supports machine stability and prevents vibration during high-speed MDF cutting. Any unevenness can affect calibration, alignment, and cut quality.

- Electrical Requirements: Stable power supply conditions reduce the risk of controller malfunction or spindle overload. Surge protectors or voltage stabilizers may be used in workshops with inconsistent electrical systems.

- Protection From Corrosive or Polluted Environments: MDF CNC routers should not be installed in areas with chemical fumes, excessive dust from unrelated processes, or high corrosion risk, as this may damage electronics and mechanical components.

What Is The Lifespan Of MDF CNC Routers?

- Overall Lifespan Expectation: High-quality MDF CNC routers generally have a lifespan of 8-15 years, depending on the machine configuration and usage intensity. Heavy-duty industrial models with reinforced frames and premium components often exceed 15 years when properly maintained.

- Frame and Structural Components: The steel frame, gantry, and worktable typically last the longest—often the entire working life of the machine. Rigid construction helps withstand continuous MDF cutting, which produces fine dust and places moderate stress on machine motion components.

- Spindle Lifespan: Spindle motors usually last 2-5 years before requiring replacement, depending on usage, cooling type, and daily operating hours. Water-cooled spindles generally achieve longer service life due to better thermal stability. Regular lubrication and proper cutting parameters help extend spindle longevity.

- Motors and Drive System: Stepper motors, easy servo motors, and servo motors typically last 5-10 years. Their longevity depends on dust management, vibration control, and workload. High-quality servo systems often maintain accuracy longer and require fewer replacements.

- Rails, Racks, and Bearings: Linear guide rails and bearings may require replacement every 3-6 years, depending on maintenance and dust control. MDF dust is fine and abrasive, so proper lubrication and sealing help preserve these components.

- Electronics and Control Systems: Control units such as Mach3, Syntec 60W-E, or Syntec 610MA-E5 generally last 8-12 years when kept in dry, clean environments. Stable voltage and proper cooling reduce electronic wear.

- Maintenance Impact: Well-maintained machines—with regular cleaning, lubrication, dust extraction, and timely part replacement—can operate far beyond their expected lifespan. Neglected maintenance significantly shortens service life, especially for spindles, rails, and motors.

- Usage Intensity: CNC routers running multiple shifts per day may require more frequent component changes, while small workshops with low to moderate workloads experience much longer machine life.

What Training Is Required To Operate MDF CNC Routers?

- Basic CNC Operation Training: Operators must understand machine components, working principles, and setup procedures. This includes learning how to power the machine, reference axes, load tools, and prepare MDF sheets correctly. Fundamental operation training ensures safe startup and shutdown routines.

- CAD/CAM Software Training: CNC routers rely on digital toolpaths generated through CAD/CAM programs. Operators should be trained to create 2D and 3D designs, generate G-code, choose appropriate machining strategies, and optimize toolpaths for MDF cutting. Training also covers nesting, tool selection, and programming feed and speed values.

- Tooling and Cutting Parameter Training: MDF requires proper spindle speeds, feed rates, bit types, and depth settings. Training includes selecting compression, up-cut, or straight bits, understanding chip evacuation needs, and adjusting parameters to prevent burning or edge chipping. Operators learn how different bit geometries affect MDF finish quality.

- Workholding and Machine Setup: Operators must know how to secure MDF sheets using vacuum tables or T-slot clamps. Training includes adjusting vacuum zones, preventing sheet movement, checking machine level, and ensuring proper alignment for large-format workpieces.

- Dust Extraction and Maintenance Training: MDF produces large volumes of fine dust. Operators must learn how to manage dust extraction systems, clean filters, inspect hoses, and maintain airflow. Training also covers daily machine cleaning, lubrication of rails, checking belts or racks, and monitoring spindle performance.

- Safety Training: CNC routers involve high-speed spindles and moving gantries. Operators must learn emergency stop procedures, safe distance practices, PPE requirements, and safe handling of MDF dust. Training ensures operators understand risks associated with tool changes and sheet loading.

- Troubleshooting and Quality Control: Operators receive training to identify issues such as vibration, burning, chatter marks, loose fixtures, or inaccurate cuts. They also learn inspection methods to verify part dimensions and ensure consistent quality.

What PPE Is Required To Operate MDF CNC Routers?

- Safety Glasses or Face Shield: Eye protection is crucial because chips, dust, and small debris can escape during tool changes, cleaning, or unexpected movement of the cutter. Impact-resistant safety glasses or a full-face shield protect against flying particles and airborne MDF fibers.

- Respiratory Protection: MDF dust contains fine wood particles and resins that can irritate the respiratory system. A properly fitted N95 mask, P100 respirator, or dust-filtering mask protects the operator from inhaling harmful dust during routing, vacuuming, or cleaning the machine. This is especially important when working with large sheets or during long production cycles.

- Hearing Protection: CNC routers generate significant noise, particularly when cutting dense MDF sheets at high speeds. Earplugs or earmuff-style hearing protectors help reduce noise exposure, prevent fatigue, and protect long-term hearing.

- Gloves (Used Selectively): Protective gloves should be worn during tool changes, bit installation, and handling MDF sheets to prevent cuts and splinters. However, gloves should not be worn near moving spindle components to avoid entanglement risks.

- Protective Clothing: Operators should wear snug, non-loose clothing to avoid getting caught in moving parts. Long sleeves, work uniforms, or workshop aprons protect against dust and debris. Jewelry, loose straps, and dangling items should be removed before the operation.

- Safety Footwear: Non-slip, steel-toed safety shoes protect the feet from falling MDF sheets, tools, or machine components. Stability is especially important when loading heavy panels onto the CNC router table.

- Dust-Proof Head and Hair Covering: For long-haired operators, hair should be tied back and covered to prevent accidental entanglement. A light dust cap or protective hat helps reduce dust accumulation.

- Visibility Aids: In busy workshops, high-visibility vests or clothing help operators stay noticeable around moving equipment and large material stocks.