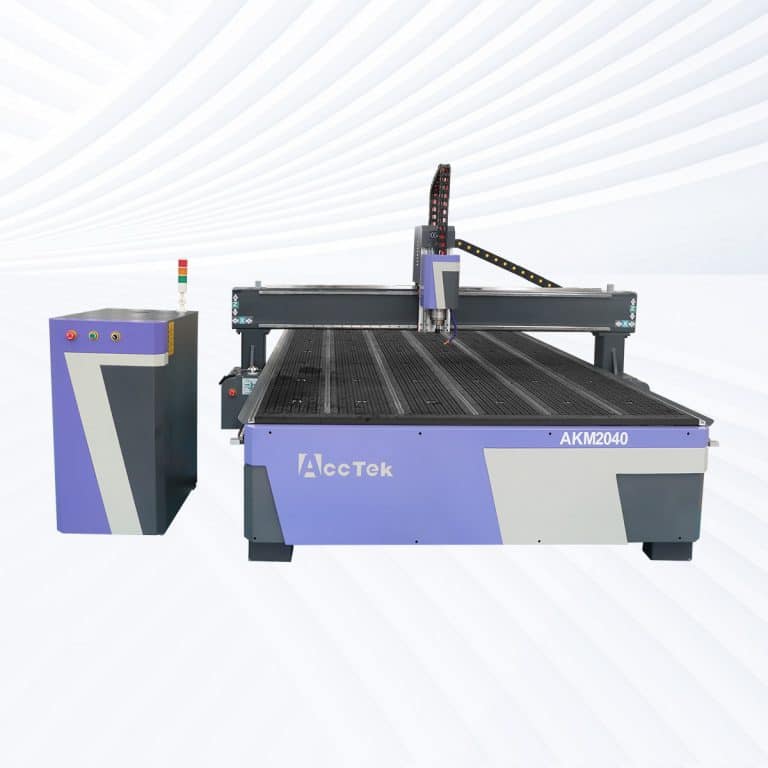

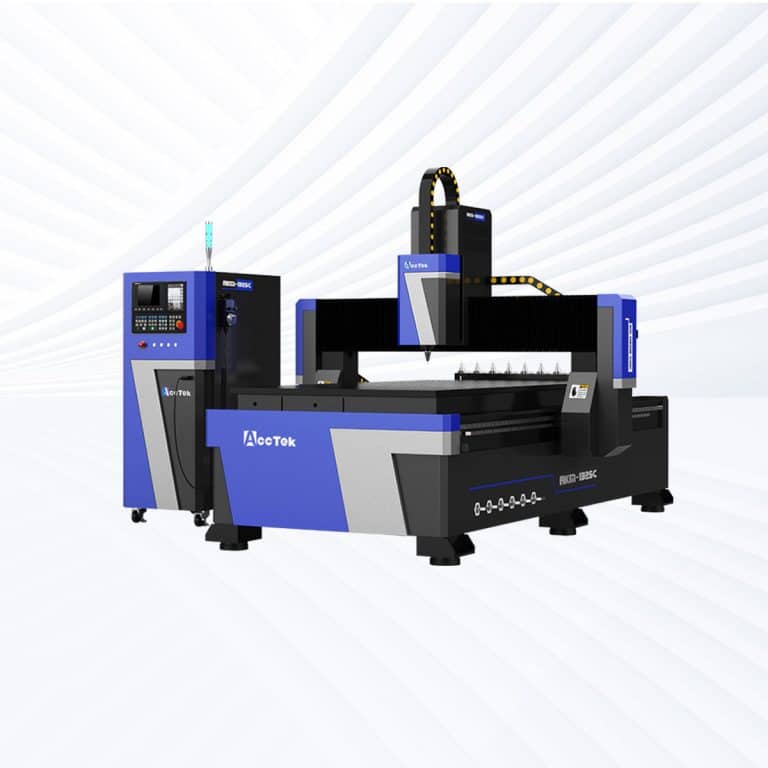

Product Introduction

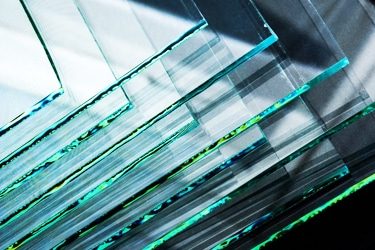

Benefits of CNC Routing Glass

High Precision and Accuracy

Glass CNC routers deliver exceptionally clean cuts and engravings, eliminating cracks and chips common with manual methods. Advanced motion controls and diamond tooling ensure every detail is executed with consistent accuracy, even on complex shapes or delicate decorative work.

Versatility Across Glass Types

From float and tempered glass to laminated, frosted, stained, and borosilicate glass, CNC routers can handle a wide variety of materials. This flexibility makes them suitable for industries ranging from architecture and interior design to automotive and electronics.

Enhanced Productivity

Automated CNC routing significantly reduces production time compared to traditional cutting methods. Intricate cuts, holes, and patterns are completed quickly and with minimal manual intervention, allowing businesses to meet deadlines and scale operations efficiently.

Superior Edge Quality

With diamond-coated tooling and water-cooled spindles, CNC routers achieve smooth, polished edges with minimal need for secondary finishing. This not only improves final product quality but also reduces labor and time spent on post-processing.

Consistency and Repeatability

Once a digital design is programmed, CNC routers can replicate it precisely across multiple pieces. This repeatability is essential for batch production of glass panels, signage, or decorative elements where uniformity is critical.

Expanded Design Capabilities

Glass CNC routers allow for the creation of intricate engravings, detailed patterns, and custom shapes that are nearly impossible to achieve manually. This capability opens new opportunities for artistic expression, branding, and innovative architectural designs.

Compatible Glass Materials

- Float Glass

- Annealed Glass

- Tempered Glass

- Laminated Glass

- Frosted Glass

- Acid-Etched Glass

- Patterned Glass

- Tinted Glass

- Clear Glass

- Ultra-Clear Glass

- Coated Glass

- Reflective Glass

- Mirror Glass

- Insulating Glass Units (IGU)

- Wired Glass

- Solar Control Glass

- Smart Glass (Switchable)

- Self-Cleaning Glass

- Bullet-Resistant Glass

- Safety Glass

- Stained Glass

- Decorative Glass Panels

- Ceramic-Frit Glass

- Sandblasted Glass

- Glass Blocks

- Bent Glass

- Curved Glass Panels

- Structural Glass Panels

- Architectural Glass Laminates

- Automotive Glass

- Marine Glass

- Shower Glass Panels

- Tabletops and Countertop Glass

- Display Glass

- Borosilicate Glass (Pyrex)

- Aluminosilicate Glass

- Fused Silica Glass

- Soda-Lime Glass

- Glass Fiber Reinforced Panels

- Specialty Coated Glass for Electronics

Application of Glass CNC Routers

Customer Testimonials

Comparison VS Other Engraving Technologies

| Feature | Glass CNC Router | Laser Engraving | Hand Engraving | Chemical Etching |

|---|---|---|---|---|

| Cutting Depth | Deep, variable (2D & 3D) | Shallow, surface marks only | Limited, depends on artisan | Very shallow, surface only |

| Precision | High accuracy, chip-free edges | Fine detail but risk of cracks | Inconsistent, skill-dependent | Moderate, mask-dependent |

| Speed | Fast for large and complex jobs | Very fast for surface engraving | Slow, labor-intensive | Moderate, multi-step process |

| Material Compatibility | Works with float, tempered, laminated, borosilicate, and more | Limited, may crack heat-sensitive glass | Any glass, but slow | Limited, not ideal for coated/treated glass |

| Complex Designs | Handles intricate 2D/3D shapes and drilling | Excellent for fine 2D details | Restricted by skill level | Restricted to flat patterns |

| Repeatability | Perfect digital repeatability | Repeatable surface engravings | Difficult to replicate | Repeatable if stencils/masks identical |

| Setup Requirements | CAD/CAM software, diamond tooling, water cooling | Software, laser calibration | No setup, just tools & skill | Masking, chemical handling, safety |

| Learning Curve | Moderate, requires training | Moderate, software-based | Very steep, years of practice | Moderate, process-sensitive |

| Production Volume | Ideal for prototyping & mass production | Suitable for medium-scale surface work | Poor, only for one-offs | Batch processing possible |

| Surface Finish | Smooth, polished edges | Risk of burns or cracks | Handmade texture | Matte, less sharp detail |

| Durability of Work | Structural & long-lasting | Surface-only, may fade/wear | Durable but inconsistent | Shallow, prone to wear |

| Customization | Easy CAD design changes | Quick digital edits | Manual, slow, less flexible | Requires new masks each time |

| Waste & Safety | Minimal waste, safe with water cooling | Minimal waste, risk of fumes | No waste, but physically demanding | Hazardous chemicals & disposal required |

| Cost Efficiency | Higher upfront, low per-part cost | Moderate cost, limited depth | Low tools, high labor cost | Low machine cost, high consumables |

| Best Use Case | Architectural glass, mirrors, panels, industrial parts | Fine logos, barcodes, shallow patterns | Artistic, unique custom work | Industrial surface markings |

Why Choose Us

High Precision & Efficiency

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Robust and Durable Design

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Intelligent Control Systems

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

Flexible Customization

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

Related Resources

How Do CNC Routers Work

This article explains the working principle of CNC routers, from the motion system and cutting tools to the software workflow, materials, precision, and actual machining principles.

How To Maintain CNC Routers

This article provides a comprehensive guide on how to maintain CNC routers, covering essential tasks, troubleshooting tips, upgrades, and best practices to ensure optimal performance and longevity.

What Is The Accuracy Of CNC Routers

This article is a comprehensive guide that explains the precision of CNC routers, the key factors affecting precision, expected performance, and how to improve machining results.

How to Choose the Right Router Bits for CNC Routers

This article explains how to select the right router bit for your CNC router, including cutter type, material, coating, and tip, to achieve precise, efficient, and durable cutting performance.

Frequently Asked Questions

How Much Do Glass CNC Routers Cost?

- 3-Axis CNC Router ($3,000–$10,000): These are entry-level machines that move along the X, Y, and Z axes. They are suitable for basic engraving, drilling, and cutting of flat glass panels. While affordable, they have limitations in handling complex shapes or deep contouring. Ideal for small workshops or businesses producing glass signage, decorative panels, or basic architectural elements.

- 4-Axis CNC Router ($12,000–$22,000): Adding a fourth axis allows for rotation of the workpiece or tool, enabling more advanced machining such as curved engravings, circular cutting, and edge profiling. These machines are well-suited for manufacturers producing glass furniture, shower enclosures, or decorative items requiring more intricate shaping.

- 5-Axis CNC Router ($57,000–$70,000): High-end machines with full five-axis motion can process glass in complex three-dimensional forms. They are used in industries such as automotive, aerospace, and high-end architecture, where precision shaping of curved or custom glass parts is required. These machines deliver the highest flexibility but come with a significant investment cost.

- ATC CNC Router ($8,000–$25,000): ATC (Automatic Tool Changer) CNC routers are equipped with systems that automatically swap tools during a job. This is especially useful in glass machining, where multiple tools are needed for drilling, engraving, polishing, and cutting. ATC machines improve efficiency and reduce downtime, making them popular in medium-to-large production environments.

- Factors Affecting Price:

- Spindle Type: Higher RPM and water-cooled spindles increase cost but are necessary for glass to prevent cracking.

- Machine Size: Larger worktables suitable for full glass sheets cost significantly more.

- Automation: Features like ATC, vacuum tables, and advanced cooling systems raise the price but improve productivity.

- Build Quality: Heavy-duty frames designed to absorb vibration cost more but ensure better precision and surface finish.

How Accurate Are Glass CNC Routers?

- Flat Glass Processing: Glass CNC routers achieve a typical positional accuracy of ±0.05 mm to ±0.1 mm when cutting, drilling, or engraving flat glass panels. This is sufficient for applications like windows, glass furniture, tabletops, and signage, where edges must be consistent and clean.

- Curved and Shaped Glass: When machining curved glass or performing edge profiling, accuracy may range from ±0.1 mm to ±0.2 mm, depending on the complexity of the shape and the axis configuration. 4-axis and 5-axis CNC routers maintain higher precision on complex geometries compared to standard 3-axis machines.

- Engraving and Etching: For fine engraving patterns, CNC routers provide repeatable accuracy at the micro-level, producing intricate designs and lettering with sharp detail. Here, stability of the spindle and vibration control play a critical role in maintaining crisp edges.

- Factors That Influence Accuracy:

- Axis Type: 5-axis machines are more precise for complex 3D shapes, while 3-axis CNC routers are best for flat, straightforward cuts.

- Cooling System: Proper water cooling of the spindle prevents thermal stress and cracking, which can compromise accuracy.

- Machine Rigidity: Heavy-duty frames reduce vibration, keeping cuts smooth and measurements consistent.

- Software Control: Advanced CNC controllers improve toolpath optimization, reducing errors in fine machining tasks.

How Do I Choose Glass CNC Routers?

- Machine Axis Configuration:

- 3-Axis CNC Routers: Best suited for flat glass cutting, engraving, and drilling. Ideal for signage, table tops, and architectural panels where operations remain on one plane.

- 4-Axis CNC Routers: Allow rotation or tilting of the tool, enabling edge beveling, angled cuts, and more complex shaping of glass. Suitable for furniture, decorative panels, and shower enclosures.

- 5-Axis CNC Routers: Provide maximum flexibility for 3D shaping, curved glass, automotive windshields, and architectural projects with non-linear contours.

- Spindle Cooling Options:

- Air-Cooled Spindles: Simple and low-maintenance but less effective for continuous heavy-duty glass processing, as overheating risks cracks or tool wear.

- Water-Cooled Spindles: Provide better heat dissipation, smoother finishes, and longer tool life. Essential for extended use and industrial-scale glass machining.

- Motor Types:

- Stepper Motors: Cost-effective and sufficient for simple glass engraving or cutting, where ultra-high precision isn’t required.

- Servo Motors: Offer higher accuracy, faster speeds, and better repeatability. Recommended for complex shapes, tight tolerances, and heavy production.

- Tooling Compatibility:

- Diamond-Coated Tools: Required for cutting, grinding, and shaping glass surfaces without chipping.

- Specialized Bits: Different tools for engraving, hole drilling, edge polishing, or deep cutting ensure flexibility for diverse applications.

- Accuracy and Stability: Look for CNC routers with reinforced frames, anti-vibration systems, and precision ball screws or linear guides. These features help maintain tolerances between ±0.05 mm and ±0.2 mm, depending on the task.

- Software and Control System: Advanced CNC controllers improve efficiency by optimizing tool paths and reducing errors. Some systems also integrate CAD/CAM software for smoother design-to-production workflows.

- Applications and Scale:

- Small Workshops: A 3-axis CNC router with a water-cooled spindle is usually sufficient for signage, decorative glass, or custom furniture.

- Mid-Size Production: A 4-axis CNC router with servo motors allows beveling, polishing, and angled cuts for higher-end work.

- Industrial Operations: A 5-axis machine is ideal for automotive glass, architectural installations, and other demanding projects.

What Problems Can Be Encountered When CNC Routing Glass?

- Cracking and Breakage: Glass is brittle, so improper tool pressure, incorrect feed rates, or sudden changes in spindle speed can cause micro-cracks or full breakage. Even small vibrations in the machine can lead to fractures.

- Chipping at Edges: When routing or drilling, glass edges are highly prone to chipping. This often happens if the wrong tool is used, if cooling is insufficient, or if the feed rate is too aggressive. Special diamond-coated bits and water cooling help minimize this issue.

- Overheating: Glass cannot withstand high heat buildup. Without proper water cooling, friction between the tool and glass can generate excessive heat, causing cracks, warping, or a rough finish.

- Tool Wear and Breakage: Diamond-coated tools are required for glass cutting, but even these wear quickly under constant use. Worn tools lead to poor surface quality, uneven cuts, and increased risk of glass damage.

- Surface Scratches: If chips or dust are not cleaned away during machining, they can scratch the glass surface as the tool passes. Continuous cleaning and water flushing are critical to avoid cosmetic damage.

- Alignment Issues: Glass sheets must be fixed securely during routing. Poor clamping or vibration can cause shifts, leading to uneven cuts, inaccurate engraving, or damaged material.

- Dust and Slurry Management: Machining glass produces fine particles and slurry, which can obscure visibility, clog cooling systems, or create safety hazards if not managed with proper water circulation and extraction systems.

- Machine Stress: Glass requires slow, careful routing, which can increase stress on the spindle and machine components if operated continuously at low speeds without proper cooling or lubrication.

How Should Glass CNC Routers Be Maintained?

- Spindle and Cooling System: Most glass CNC routers use water-cooled spindles to prevent overheating. Regularly check coolant levels, water pumps, and hoses for leaks or blockages. Replace or clean coolant filters as needed, and flush the system to avoid the buildup of glass dust or slurry that could reduce cooling efficiency.

- Tooling and Collets: Diamond-coated tools wear faster than tools for softer materials. Inspect tooling frequently for wear, cracks, or uneven edges, and replace when needed to maintain cut quality and reduce stress on the machine. Clean collets and tool holders regularly to prevent slippage and vibration during routing.

- Dust and Slurry Removal: Glass cutting produces fine dust and slurry that can damage the machine if not removed. Maintain dust extraction or water flushing systems daily, and clean collection tanks and filters to ensure they remain efficient. Never allow slurry to dry on machine surfaces, as it can scratch both glass and machine parts.

- Lubrication and Linear Guides: Glass routing requires precise, smooth motion. Lubricate ball screws, bearings, and linear guides according to the manufacturer’s schedule. Keep guide rails clean and free of glass dust to prevent premature wear or positioning errors.

- Workholding and Machine Bed: Secure clamping is essential for glass. Inspect vacuum tables, clamps, or fixtures regularly to ensure they hold materials firmly without slipping. Check for chips or scratches on the machine bed and clean it frequently to avoid misalignment or uneven support.

- Electrical and Software Systems: Glass CNC routers often use advanced software for precision cutting. Perform routine checks on wiring, control boards, and sensors to ensure reliable operation. Back up machine software and CNC programs regularly to avoid data loss.

- General Cleaning and Safety Checks: After every use, wipe down machine surfaces and remove debris. Inspect safety guards, emergency stop buttons, and coolant lines to confirm they function correctly. A well-kept machine not only performs better but also improves operator safety.

What Problems Can Be Encountered When CNC Routing Glass?

- Material Fragility: Glass is brittle and prone to cracking or shattering under stress. Improper feeds, speeds, or tool pressure can cause edge chipping, surface cracks, or even complete material breakage. Using the wrong tool geometry or excessive force is a common cause of damage.

- Tool Wear and Breakage: Diamond-coated tools are essential for glass, but they wear faster than tools used for softer materials. Worn tools lead to poor edge quality, a higher risk of fractures, and increased costs due to frequent replacements. Incorrect tool maintenance can also result in breakage during operation.

- Heat Generation: Glass cutting generates friction and heat, which can cause micro-cracks or thermal stress in the material. Without adequate water cooling or misting, both the workpiece and the cutting tools can be damaged, reducing overall precision and durability.

- Dust and Slurry Management: CNC routing of glass produces fine dust and slurry that can scratch the surface if not removed properly. Accumulated slurry can clog coolant systems, reduce visibility, and create a hazardous working environment if not adequately filtered and extracted.

- Clamping and Workholding Issues: Glass requires very secure but delicate clamping. Insufficient clamping may allow material movement, causing misalignment or fractures, while excessive pressure can crack the workpiece. Vacuum beds and fixtures must be carefully maintained to hold glass evenly.

- Surface Finish Challenges: Achieving smooth glass edges can be difficult. Poor parameter settings or dull tools often result in rough edges, chipping, or uneven finishes, requiring additional polishing and increasing production time.

- Machine Stress and Accuracy: Because glass is unforgiving, even small machine vibrations or misalignments can damage the cut. Poor maintenance of guide rails, bearings, or spindles can lead to inaccurate cuts and costly scrap.

- Operator Safety Risks: Broken glass pieces, fine silica dust, and coolant-contaminated slurry pose risks to operators if proper protective equipment and extraction systems are not used. Handling errors can also lead to cuts or other injuries.

What Are The Environmental Requirements For Using Glass CNC Routers?

- Temperature and Humidity Control: Glass is sensitive to sudden temperature changes, which can cause thermal stress or cracking. The CNC router should be placed in a climate-controlled environment with stable room temperature (ideally 18–25℃) and moderate humidity (40–60%) to minimize material expansion, contraction, or condensation on machine components.

- Dust and Slurry Extraction: Cutting glass produces fine dust and water-based slurry that can be abrasive and harmful. A proper dust extraction and slurry collection system is essential to keep the work area clean, prevent airborne particles, and protect operators’ respiratory health. Filters and separators should be maintained regularly to ensure efficiency.

- Ventilation: Adequate ventilation is needed to remove mist, fine particles, and any chemical additives from coolants. Poor ventilation can lead to glass dust accumulation, which increases the risk of contamination, surface defects, and health hazards for operators.

- Coolant and Water Management: Glass CNC routers require constant water cooling to prevent overheating and cracking. The environment must allow for a reliable water supply, proper drainage, and coolant recycling systems to minimize waste and ensure continuous operation. Spent coolant should be filtered to remove glass particles before reuse.

- Work Area Cleanliness: A clean, dust-free environment is essential for precision work. Stray particles can scratch glass surfaces or interfere with vacuum tables used for workholding. Floors and machine surroundings should be cleaned frequently to prevent contamination.

- Noise and Vibration Control: Glass CNC routers generate significant noise and vibration during operation. Machines should be installed in areas with vibration-dampening flooring and, if possible, noise insulation to protect both the machine’s accuracy and operator comfort.

- Power Supply Stability: Precision CNC routing requires a stable power supply. Voltage fluctuations or surges can disrupt spindle motors, stepper or servo systems, and control electronics. Facilities should use surge protection or voltage stabilizers to ensure consistent operation.

- Safety and Operator Protection: Since glass routing carries risks of breakage and sharp fragments, the environment must include protective barriers or enclosures around the machine, along with proper PPE storage (safety glasses, gloves, masks). Adequate lighting should be installed to allow operators to monitor cutting and detect cracks or edge defects.

What PPE Do Operators Need When CNC Routing Glass?

- Eye and Face Protection: Safety goggles or a full-face shield are critical, as routing glass can produce sharp splinters and fine particles that pose a high risk of eye injury. Operators should wear impact-resistant, sealed goggles to block dust and protect against coolant splashes. A face shield adds extra protection during machine setup and when handling cut glass pieces.

- Respiratory Protection: Glass dust is extremely fine and can irritate the lungs if inhaled. Even with dust extraction systems, operators should use N95 or higher-grade respirators when working around open machines, especially during cleanup or maintenance. For prolonged work in environments with high dust levels, a powered air-purifying respirator (PAPR) may be required.

- Hand Protection: Cut-resistant gloves (such as Kevlar or nitrile-coated varieties) are necessary when handling raw glass sheets, sharp offcuts, or finished parts. During machine operation, gloves should only be worn if safe and not near rotating spindles; otherwise, bare hands are safer to avoid entanglement. However, gloves must always be used when removing material, loading, or cleaning up fragments.

- Hearing Protection: CNC glass routing generates significant noise from high-speed spindles and coolant systems. Operators should wear earmuffs or earplugs rated for industrial noise reduction to prevent long-term hearing damage, particularly in high-production environments.

- Protective Clothing: Long-sleeved, snug-fitting clothing or lab-style coats help protect skin from sharp fragments and coolant mist. Loose clothing should be avoided to prevent entanglement. Aprons made of cut-resistant or waterproof material may also be used when handling large panels or cleaning slurry.

- Foot Protection: Safety shoes with steel or composite toe caps are required, as handling large glass sheets presents a risk of dropping heavy or sharp-edged pieces. Slip-resistant soles are also important to prevent accidents in wet environments where coolant or slurry may be present.

- Head Protection (When Required): In facilities handling large glass panels or using overhead cranes, operators may also require bump caps or hard hats for protection against falling material.