Product Introduction

Benefits of CNC Routing Foam

Precision and Accuracy

Foam CNC routers deliver clean, smooth edges and exact dimensions that manual cutting cannot achieve. Even with lightweight or porous foams, CNC routing ensures accuracy in every cut, reducing errors and guaranteeing professional results for both prototypes and finished products.

Efficient Production Speed

By automating cutting, carving, and shaping, CNC routers drastically reduce production time. Complex 2D or 3D designs can be processed quickly, enabling businesses to increase throughput, meet tight deadlines, and achieve consistent results without compromising quality.

Versatility Across Foam Types

From EPS and XPS to polyurethane, polyethylene, and PVC foam board, CNC routers can process a wide range of foam materials. This versatility makes them ideal for industries like packaging, advertising, furniture, automotive, aerospace, and architectural modeling.

Reduced Material Waste

CNC routers optimize cutting paths and minimize errors, ensuring maximum material utilization. This efficiency is especially important in large-scale foam applications, where reducing waste directly lowers costs and improves sustainability in production workflows.

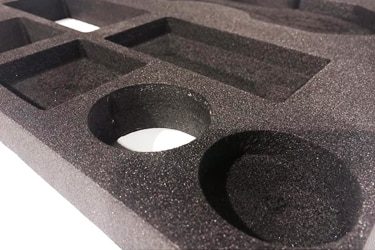

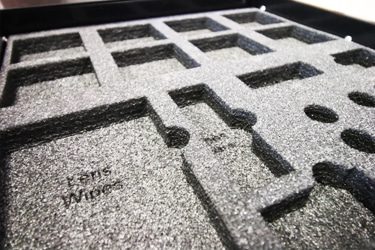

Complex Design Capabilities

CNC routing allows the creation of intricate shapes, deep cavities, 3D contours, and detailed engravings that would be difficult or impossible to achieve manually. This capability expands design possibilities for molds, prototypes, signage, packaging, and architectural models.

Scalability and Repeatability

Once programmed, CNC routers can reproduce the same design with perfect consistency. This makes them ideal for both one-off custom projects and mass production, supporting scalability while maintaining uniform quality across every foam component manufactured.

Compatible Foam Materials

- Expanded Polystyrene

- Extruded Polystyrene

- Polyurethane Foam

- Rigid Polyurethane Foam Sheets

- Flexible Polyurethane Foam

- High-Density PU Foam

- Low-Density PU Foam

- Polyethylene Foam

- Cross-Linked Polyethylene Foam

- Expanded Polyethylene

- Polypropylene Foam

- Expanded Polypropylene

- Polystyrene Foam Sheets

- High-Impact Polystyrene Foam

- Phenolic Foam

- PVC Foam Board

- Expanded PVC Foam

- Rigid PVC Foam Sheets

- PET Foam

- EVA Foam

- Memory Foam

- Neoprene Foam

- Nitrile Rubber Foam

- EPDM Foam

- Silicone Foam

- Polyimide Foam

- Melamine Foam

- Urethane Tooling Foam

- Structural Foam Boards

- Core Foam Panels for Composites

- Foam Glass Panels

- Acoustic Foam Panels

- Insulation Foam Sheets

- Marine-Grade Foam Panels

- Fire-Retardant Foam

- High-Resilience Foam

- Open-Cell Foam

- Closed-Cell Foam

- Balsa-Core Foam Sandwich Panels

- Composite Foam Laminates

Application of Foam CNC Routers

Customer Testimonials

Comparison VS Other Engraving Technologies

| Feature | Foam CNC Router | Laser Engraving | Hand Engraving | Chemical Etching |

|---|---|---|---|---|

| Cutting Depth | Deep, variable (2D & 3D) | Shallow, burns foam | Variable, limited by skill | Very shallow, not ideal for foam |

| Precision | High, consistent accuracy | Can melt edges, less clean | Inconsistent, hand-dependent | Limited detail, uneven results |

| Speed | Fast for large or complex projects | Fast for surface marking only | Slow, labor-intensive | Moderate, multi-step process |

| Material Compatibility | Works with most foam types (EPS, XPS, PU, PVC, etc.) | Limited, risk of melting/discoloration | Any workable foam, slow | Rarely suitable for foam |

| Complex Designs | Handles intricate 2D/3D shapes | Limited to 2D surface detail | Dependent on artisan skill | Restricted to flat, masked designs |

| Repeatability | Perfectly repeatable with CAD/CAM | Repeatable for shallow engraving | Hard to replicate consistently | Repeatable if masks are identical |

| Setup Requirements | CAD/CAM software, tooling, vacuum hold-down | Software, laser calibration | No software, just tools & skill | Masking, chemical handling, safety gear |

| Learning Curve | Moderate, requires training | Moderate, software-driven | Very steep, years of practice | Moderate, process knowledge needed |

| Production Volume | Excellent for prototyping & mass production | Medium-scale surface jobs only | Not suited for large volumes | Suitable for batch runs, not foam |

| Surface Finish | Smooth, clean edges, no burns | Burned edges, discoloration likely | Textured, handmade finish | Matte finish, poor quality on foam |

| Durability of Work | Structural carvings & models | Surface only, can wear easily | Durable but inconsistent | Not durable, shallow markings |

| Customization | Easy digital adjustments | Quick design changes | Manual, slow, less flexible | New masks required for changes |

| Waste & Safety | Minimal waste; dust extraction needed | Minimal waste but toxic fumes | No waste, but slow | Hazardous chemicals & disposal issues |

| Cost Efficiency | Higher upfront, low per-part cost | Moderate setup, limited use for foam | Low tool cost, high labor cost | Low equipment, high chemical cost |

| Best Use Case | Packaging, signage, prototypes, molds, models | Fine surface detail, logos | Artistic one-of-a-kind foam art | Industrial marking, not foam-friendly |

Why Choose Us

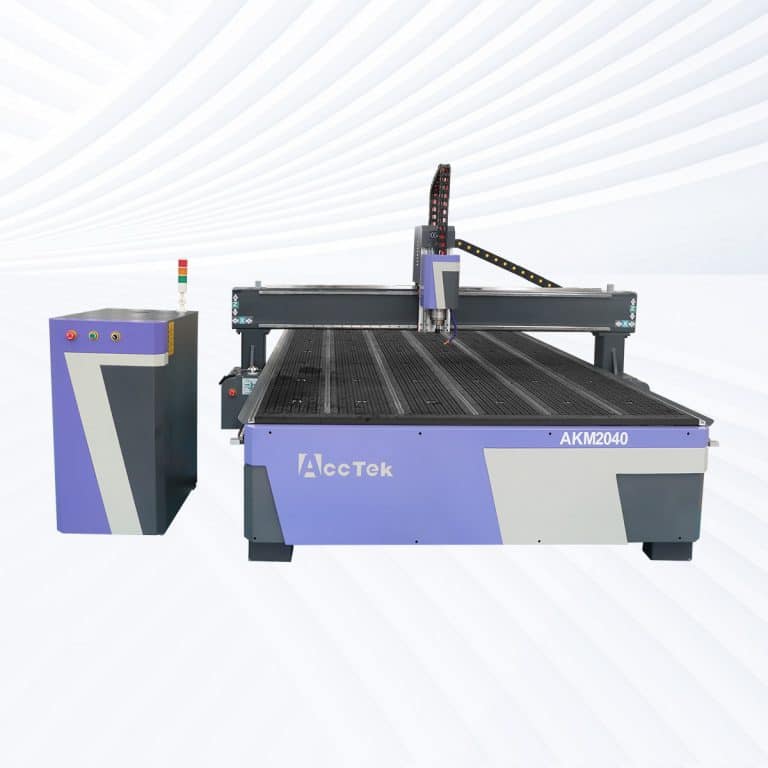

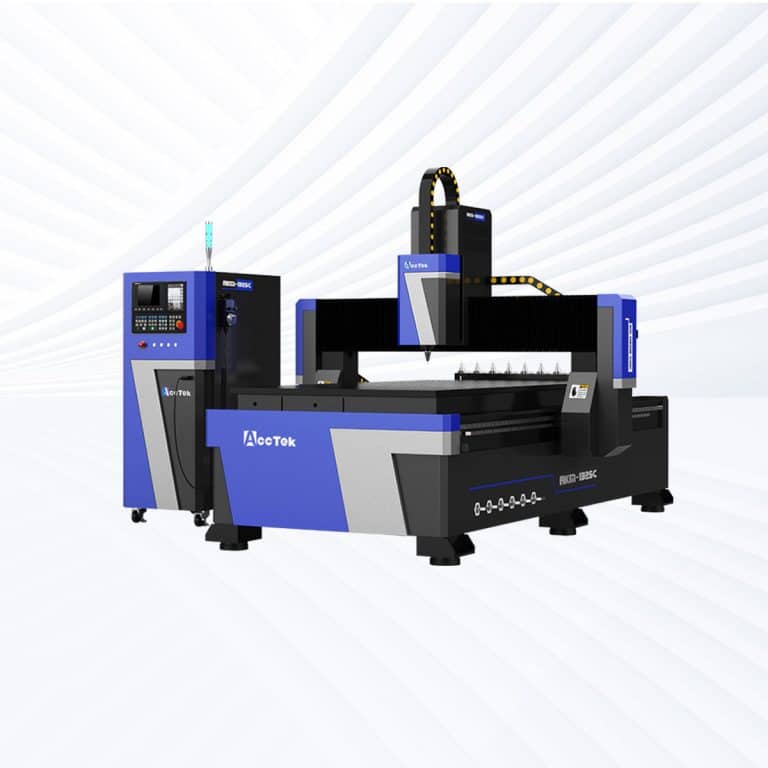

High Precision & Efficiency

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Robust and Durable Design

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Intelligent Control Systems

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

Flexible Customization

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

Related Resources

What Is The Accuracy Of CNC Routers

This article is a comprehensive guide that explains the precision of CNC routers, the key factors affecting precision, expected performance, and how to improve machining results.

How to Choose the Right Router Bits for CNC Routers

This article explains how to select the right router bit for your CNC router, including cutter type, material, coating, and tip, to achieve precise, efficient, and durable cutting performance.

Stepper Motor VS Servo Motor

This article compares stepper motors and servo motors, detailing their working principles, performance characteristics, applications, and key differences in modern automation.

How to Choose the Right CNC Router Spindle

This article explains how to choose the right CNC router spindle by detailing key factors such as power, torque, speed range, cooling type, precision, and machine compatibility.

Frequently Asked Questions

How Much Do Foam CNC Routers Cost?

- 3-Axis CNC Router: $3,000 – $10,000. These are entry-level foam CNC routers, ideal for straightforward 2D and simple 3D cutting. They are commonly used in packaging, signage, and architectural modeling. Affordable and reliable, they are perfect for small workshops or startups.

- 4-Axis CNC Router: $12,000 – $22,000. A step up in flexibility, 4-axis CNC routers allow rotary cutting and more complex shapes. They are suited for detailed molds, 3D models, and curved foam components. The added axis increases versatility, making them popular with medium-sized manufacturers.

- 5-Axis CNC Router: $57,000 – $70,000. These high-end machines provide the ultimate in precision and complexity. They can cut intricate 3D geometries from all angles, making them essential for aerospace, automotive, and marine industries. Their advanced capabilities justify the higher investment.

- ATC (Automatic Tool Changer) CNC Router: $8,000 – $25,000. Designed for efficiency, ATC CNC routers automatically switch tools during cutting, saving time on large or complex projects. They’re excellent for scaling production while minimizing downtime, offering a balance between speed and versatility.

What Rotational Speed Is Required For Using CNC Routing Foam?

- Low-Density Foams (EPS, XPS, EPE): These foams are lightweight and cut easily at 18,000–24,000 RPM. Higher speeds prevent tearing and produce smooth edges, making them ideal for packaging, architectural models, and signage.

- Medium-Density Foams (Polyurethane, Polyethylene, PVC Foam Board): Require spindle speeds of 15,000–22,000 RPM. These foams are tougher and need slightly slower speeds to prevent tool chatter while maintaining accuracy in detailed cuts and 3D shapes.

- High-Density Foams (Tooling Foam, Structural Core Foam, High-Density PU): Best processed at 12,000–18,000 RPM with sharp tools. Too high a speed can cause melting or excessive heat buildup, while slower, steadier cutting ensures precision and durability of the part.

- Specialty Foams (EVA Foam, Memory Foam, Acoustic Foam): Work best at 16,000–20,000 RPM, with toolpath optimization and sharp cutters to prevent fraying edges.

How Do I Purchase Foam CNC Routers?

- Direct from Manufacturers: Many CNC router manufacturers sell foam CNC routers directly through their websites or sales teams. This option ensures you get the latest models, official warranties, and customization options such as table size, spindle type, or automatic tool changers. While often the most reliable source, prices may be higher compared to third-party sellers.

- Authorized Dealers and Distributors: Dealers represent multiple brands and provide localized support, including installation, training, and after-sales service. Buying through a distributor often gives access to financing options, bundled accessories, and expert advice tailored to specific applications like packaging foam, mold-making, or sign production.

- Online Marketplaces: Platforms such as Alibaba, Amazon, and eBay list a wide variety of foam CNC routers, from small desktop machines to industrial models. This option allows easy price comparison and access to global sellers. However, buyers must carefully check the seller’s reputation, return policies, and whether technical support or spare parts are available.

- Specialized CNC Retailers: Some retailers focus exclusively on CNC machines and accessories. They often provide detailed technical support, machine demonstrations, and recommendations for tooling and software suited for foam. While slightly more expensive, this route is ideal for buyers who value professional guidance.

- Second-Hand Market: Used foam CNC routers can be purchased through auctions, resellers, or private sellers. Buying second-hand significantly reduces upfront costs, but it comes with risks such as worn components, outdated control systems, or missing warranties. Experienced operators who can inspect and refurbish machines may find good value in this option.

- Trade Shows and Expos: Industry exhibitions showcase CNC router brands and models in one place. Buyers can see live demonstrations, compare features directly, and negotiate pricing with sales representatives. Trade shows are particularly useful for professionals seeking large-scale machines or tailored solutions for industrial foam applications.

Is CNC Routing Foam Safe?

- Dust and Particle Generation: Foam machining produces small chips and fine particles that can become airborne. While less harmful than wood or composite dust, they can still irritate the lungs and skin. Using a strong dust collection system and wearing a respirator or dust mask minimizes exposure.

- Flammability and Heat Risks: Many foams, including polyurethane and polystyrene, are flammable. If router bits dull or generate excessive heat, foam edges may melt, scorch, or, in rare cases, ignite. Maintaining sharp tooling, proper feed rates, and good ventilation reduces fire risk.

- Static Electricity: Foam chips are lightweight and can build static charges, causing them to cling to surfaces, machines, or operators. This makes cleanup more difficult and may interfere with accuracy. Anti-static dust extraction systems or grounding methods help control static buildup.

- Material Handling Hazards: Large foam sheets are lightweight but bulky, making them awkward to handle. Improper lifting can cause strain or imbalance. For industrial setups, material handling aids such as rollers, carts, or vacuum lifters improve safety and efficiency.

- Noise and Operator Comfort: Foam machining is typically quieter than routing harder materials, but spindle and dust collector noise still requires hearing protection. In enclosed workshops, sound levels can rise quickly without noise reduction measures.

- Tool Wear and Breakage: Though softer than wood or composites, foam can still damage tools if feed rates are poorly set. Melting foam can stick to bits, causing tool clogging and potential breakage. Regular inspection and cleaning of bits ensure safer operation.

- Chemical Exposure: Some foams, especially when overheated, can release unpleasant odors or fumes. While not always hazardous, certain industrial foams (e.g., PVC-based foams) may release toxic gases when cut and should be avoided. Always confirm material safety before machining.

What Problems Can Be Encountered When Using Foam CNC Routers?

- Melting and Poor Edge Quality: Certain foams, like polystyrene or polyurethane, can melt when router bits generate too much heat. This causes rough or uneven edges and may leave melted residue on the tool. Using sharp bits, proper feeds and speeds, and cooling air assist helps prevent melting.

- Static Electricity and Chip Clinging: Foam chips are lightweight and prone to static buildup, making them cling to machine surfaces, tools, and even operators. This complicates cleanup and can interfere with accuracy. Anti-static dust extraction systems or grounding solutions help manage this issue.

- Dust and Airborne Particles: Routing foam produces fine dust that can spread quickly in the workshop. While less abrasive than wood or composites, this dust still poses health risks if inhaled and can settle on electronics or moving parts. Effective dust collection and PPE are essential.

- Workholding Challenges: Foam sheets are lightweight but bulky, making them prone to shifting or vibrating under the router bit. Poor fixturing can result in inaccurate cuts, rough finishes, or wasted material. Vacuum tables, custom clamps, or adhesive mats improve stability.

- Tool Clogging and Wear: Foam can clog router bits if feed rates are too slow or if the bit design is not suited to lightweight materials. This leads to friction, poor finishes, or even bit breakage. Choosing bits specifically designed for foam, with open flute designs, minimizes clogging.

- Inconsistent Material Density: Foam materials vary in density and quality. Inconsistent density may cause uneven cuts, poor surface finishes, or structural weakness in the final product. Adjusting toolpaths and making test cuts help ensure reliable results.

- Fire and Heat Risks: Foam is flammable, and accumulated dust or excessive tool heat can pose a fire hazard. While rare, the risk is higher with closed-cell foams like polyurethane. Maintaining sharp tools, proper feeds, and a clean workspace minimizes this danger.

- Surface Finish Limitations: Some foams, particularly low-density types, tear or crumble when routed. This creates rough edges or fuzzy surfaces that may require secondary finishing. High-density foams produce cleaner results but wear tools faster.

What Training Is Required To Operate Foam CNC Routers?

- Basic Machine Operation: Operators must learn how to start up, shut down, and control the CNC router safely. This includes homing the axes, setting workpiece zero points, loading files, and running toolpaths. Training also covers emergency stop functions and safe procedures in case of errors.

- CAD and CAM Software Skills: Foam CNC routers rely on CAD (Computer-Aided Design) for creating models and CAM (Computer-Aided Manufacturing) for generating toolpaths. Training includes designing parts, selecting appropriate cutting strategies for foam, and exporting G-code files correctly for the machine.

- Tool Selection and Setup: Different foams require specific tools for clean results. Operators must know how to choose bits with open flute designs that prevent clogging, install them correctly, and inspect for wear. Training also covers safe tool changes and spindle setup.

- Feeds, Speeds, and Machining Parameters: Foam cuts differently than wood or plastics. Training emphasizes how to set spindle speeds and feed rates to avoid problems like melting, tearing, or rough surfaces. Operators learn how to balance speed and precision for both high-density and low-density foams.

- Workholding and Fixturing: Foam sheets are lightweight and prone to vibration, so proper hold-down methods are critical. Training covers the use of vacuum tables, clamps, or adhesive mats to keep foam stable during cutting without damaging the material.

- Dust and Chip Management: Even though foam is softer, routing creates dust and small particles that can spread easily. Operators need to understand how to use dust extraction systems effectively, manage static buildup, and wear appropriate protective gear like masks or respirators.

- Maintenance and Troubleshooting: Foam can clog tools and build up on machine parts. Training covers daily cleaning, spindle checks, lubrication, and inspection of bits for wear. Operators also learn troubleshooting steps for issues like melting edges, static cling, or uneven cuts.

- Safety and Material Knowledge: Not all foams are safe to route. Training includes identifying which foams (like EVA, polyethylene, or polystyrene) are commonly used and safe, while avoiding materials that release hazardous fumes when cut. Safety procedures, including fire prevention and PPE use, are also emphasized.

What Are The Environmental Requirements For Using Foam CNC Routers?

- Ventilation and Air Quality: Foam machining generates fine dust and, in some cases, light fumes when edges melt. A well-ventilated workshop with air extraction systems prevents the buildup of airborne particles. For enclosed spaces, an additional air purifier or filtration system is recommended.

- Dust and Static Control: Foam chips are lightweight and often cling to surfaces due to static electricity. A high-efficiency dust collection system helps keep the workspace clean and prevents particles from interfering with accuracy. Anti-static features on dust extractors or grounding methods reduce static buildup.

- Temperature Control: Foam is sensitive to heat. High workshop temperatures can cause softening or distortion, while low temperatures may make some foams brittle and prone to tearing. Maintaining a stable, moderate room temperature ensures predictable cutting performance.

- Humidity Management: Foams generally absorb little moisture, but extreme humidity can increase static buildup and may affect adhesives or fixtures used for hold-down. Keeping humidity within a balanced range improves machine reliability and operator comfort.

- Electrical Stability: CNC routers require a steady power supply for spindles, motors, and control systems. Voltage fluctuations or power outages can interrupt jobs and damage electronics. Surge protectors or an uninterruptible power supply (UPS) protect equipment and prevent data loss.

- Workspace Layout and Safety: Foam sheets are often large and bulky, requiring adequate space for handling and movement around the CNC router. Clear walkways, proper material storage, and safe zones around the machine reduce the risk of accidents. Fire extinguishers should also be accessible due to the flammable nature of some foams.

- Noise Considerations: Routing foam is quieter than cutting harder materials, but spindle motors and dust collectors still generate significant noise. Adequate acoustic management or hearing protection ensures a safer and more comfortable working environment.

- Cooling and Air Assist: While foam is typically cut dry, air-assist systems help clear chips from the toolpath and reduce melting on heat-sensitive foams. Ensuring the shop has a proper compressed air supply or auxiliary cooling improves cut quality and tool life.

How Should Foam CNC Routers Be Maintained?

- Dust and Chip Removal: Foam machining produces lightweight chips and fine dust that can quickly accumulate inside the machine. Daily cleaning with a vacuum or compressed air prevents buildup on rails, motors, and electronics. Keeping the dust collection system clear and replacing filters regularly ensures consistent performance.

- Tool and Spindle Care: Foam is less abrasive than wood or composites, but router bits can still dull or clog with melted residue. Regular inspection, cleaning, and replacement of tools is necessary for clean cuts. Spindles should also be monitored for vibration, overheating, or unusual noise, which may indicate bearing wear.

- Lubrication of Moving Parts: Linear rails, ball screws, and bearings require lubrication according to manufacturer guidelines. Even though foam dust is softer, it can still infiltrate moving parts and cause wear over time. Proper lubrication minimizes friction and maintains smooth motion.

- Calibration and Alignment: Foam is forgiving compared to dense materials, but consistent calibration ensures precision in cuts, especially for 3D models and prototypes. Checking axis alignment, squareness, and zero points regularly prevents cumulative errors.

- Cooling and Air Assist Systems: If the machine uses air assist to clear chips, the air lines and filters should be inspected to prevent blockages. For water-cooled spindles, coolant reservoirs must be checked for fluid levels, leaks, and cleanliness to ensure efficient cooling.

- Inspection of Belts and Drive Components: Belts, couplings, and motors should be checked for wear or looseness. Foam CNC routers often run at high speeds, which can stress drive components if they are not properly maintained. Timely replacement of worn parts prevents breakdowns.

- Electrical and Control Systems: Dust can settle inside control boxes, reducing cooling efficiency or causing short circuits. Periodic cleaning and inspection of electrical systems, along with keeping firmware and software up to date, ensure reliable operation.

- Workholding Maintenance: Vacuum tables, clamps, or adhesive mats used for foam hold-down must be cleaned and inspected. Foam dust can clog vacuum ports, reducing suction power, while adhesive mats need replacement when worn out.