Product Introduction

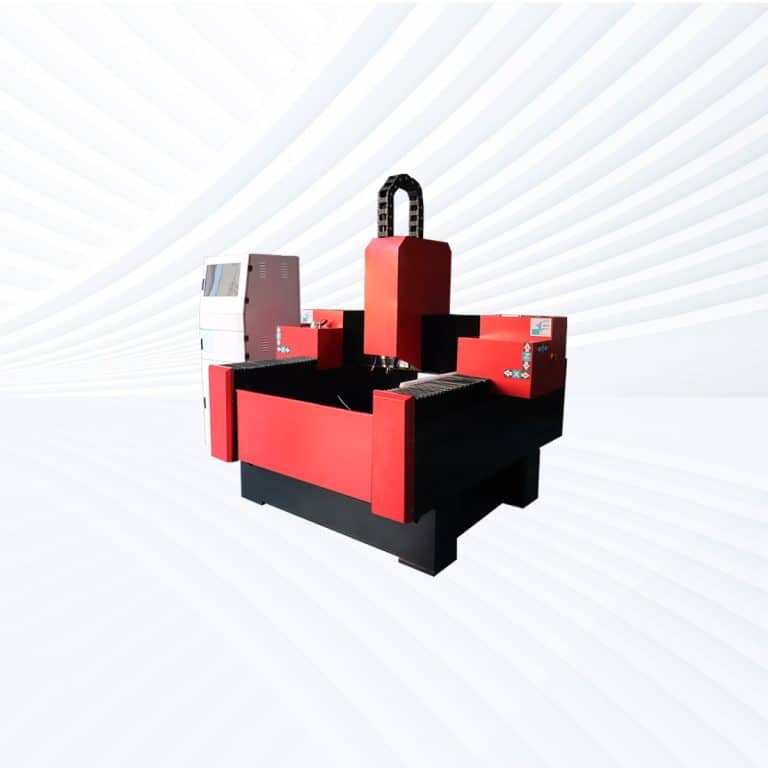

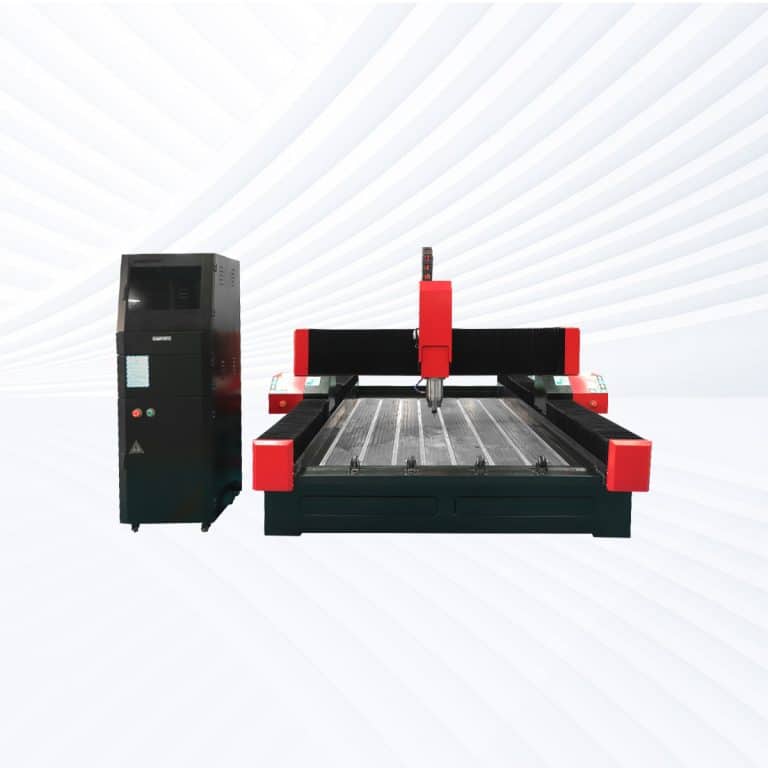

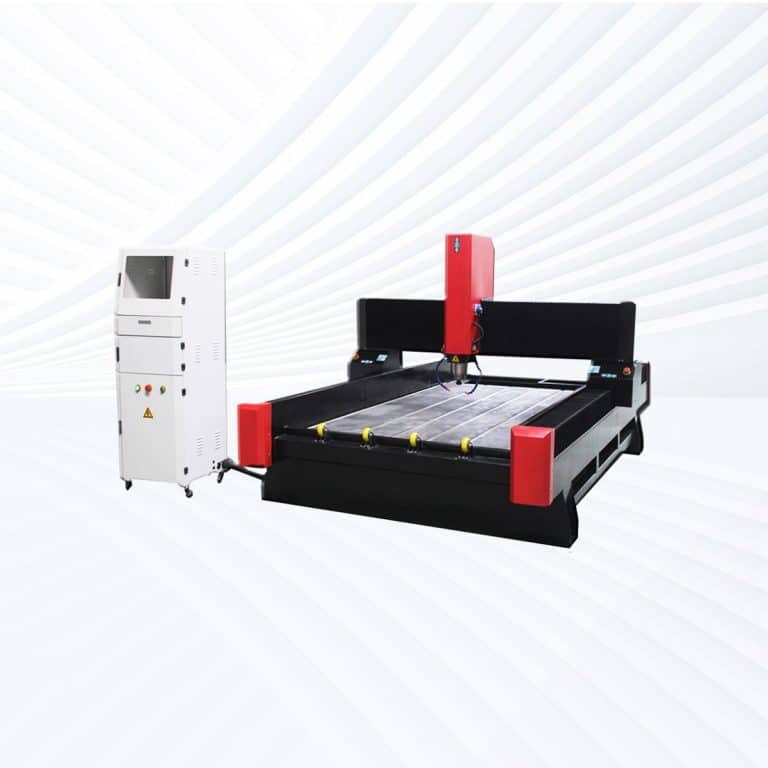

Types of Composite CNC Routers

Benefits of CNC Routing Composite

Precision Cutting of Tough Materials

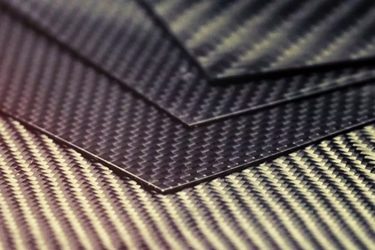

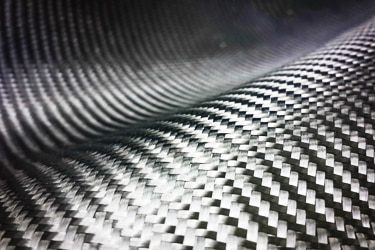

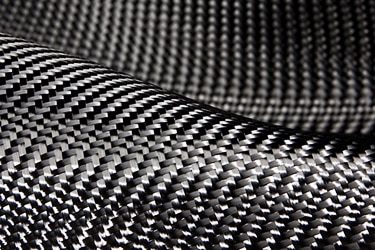

Composites like carbon fiber and fiberglass are notoriously difficult to process with traditional tools. CNC routers deliver clean, accurate cuts with minimal delamination or fraying, ensuring components meet strict dimensional tolerances and performance requirements across industries.

Increased Production Efficiency

Automated routing speeds up production cycles by handling complex shapes and repetitive tasks with ease. This allows businesses to process composite panels, laminates, or structural parts faster, reducing labor costs and accelerating time-to-market without compromising quality.

Consistent Repeatability

CNC technology guarantees identical results from the first cut to the last. Once programmed, the machine can reproduce designs precisely, making it ideal for batch production of composite components that require uniform strength, fit, and performance.

Design Flexibility and Complexity

From intricate contours to advanced 3D geometries, CNC routers provide the flexibility to produce composite parts that meet demanding design specifications. This opens opportunities for innovation in aerospace, automotive, marine, and architectural applications.

Reduced Material Waste

Composites are costly materials. CNC routers optimize toolpaths to maximize sheet utilization and minimize offcuts. By reducing errors and waste, they lower material costs and contribute to more sustainable manufacturing practices.

Enhanced Safety and Clean Operation

Routing composite generates dust and particles that can be hazardous. Modern CNC routers integrate dust collection and extraction systems, ensuring a safer working environment while maintaining the integrity of both operators and finished parts.

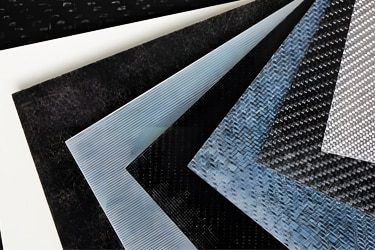

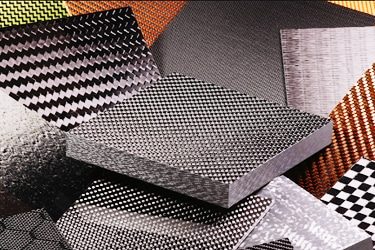

Compatible Composite Materials

- Carbon Fiber Reinforced Polymer

- Glass Fiber Reinforced Polymer

- Kevlar® Composites

- Aramid Fiber Composites

- Fiberglass Laminates

- Phenolic Laminates

- Epoxy Resin Composites

- Polyester Resin Composites

- Vinyl Ester Composites

- Polypropylene Composites

- Polyethylene Composites

- Thermoplastic Composites

- Thermoset Composites

- CFRP Honeycomb Panels

- Aluminum Honeycomb Composites

- Nomex® Honeycomb Composites

- Foam-Core Sandwich Panels

- Balsa Core Composites

- PET Foam Core Composites

- PVC Foam Core Composites

- Marine-Grade Laminates

- Aerospace-Grade Laminates

- Automotive Composites

- Fiber Reinforced Plastics

- Sheet Molding Compound

- Bulk Molding Compound

- Phenolic Composites

- Pultruded FRP Profiles

- Ceramic Matrix Composites

- Metal Matrix Composites

- Basalt Fiber Composites

- Quartz Fiber Composites

- Graphene-Reinforced Composites

- Nano-Composite Panels

- CFRP Prepreg Sheets

- GFRP Prepreg Sheets

- Pultruded Composite Profiles

- Composite Tubes and Rods

- Laminated Safety Panels

- Composite Decorative Panels

Application of Composite CNC Routers

Customer Testimonials

Comparison VS Other Engraving Technologies

| Feature | Composite CNC Router | Laser Engraving | Hand Engraving | Chemical Etching |

|---|---|---|---|---|

| Cutting Depth | Deep, adjustable, suitable for 2D & 3D work | Shallow, mostly surface-level | Variable, limited by skill | Very shallow, surface only |

| Precision | High accuracy on tough composites | Very fine on surface details | Inconsistent, depends on artisan | Moderate, influenced by masking process |

| Speed | Fast for complex geometries & large sheets | Very fast for surface markings | Slow, labor-intensive | Moderate, multiple processing steps |

| Material Compatibility | Wide range: carbon fiber, fiberglass, Kevlar, honeycomb, laminates | Limited, risk of burning/delamination | Works on some, but laborious | Limited; not all composites are etchable |

| Complex Designs | Handles intricate 2D/3D shapes | Excellent for 2D patterns | Limited to craftsman’s ability | Suitable for detailed 2D designs |

| Repeatability | Perfectly repeatable from digital files | Repeatable on surface markings | Difficult to replicate consistently | High once stencils/masks are prepared |

| Setup Requirements | CAD/CAM software, tooling, and fixturing | Design software, laser calibration | None beyond tools & skill | Masking, chemical handling, safety equipment |

| Learning Curve | Moderate, training required | Moderate, software-focused | Very steep, years of practice | Moderate, process knowledge needed |

| Production Volume | Ideal for prototypes and large-scale runs | Good for medium-scale production | Not practical for high volume | Suited for batch production |

| Surface Finish | Clean edges, minimal delamination with proper tooling | Burn marks, discoloration possible | Textured, handmade look | Matte finish, less sharp |

| Durability of Work | Produces strong, structural components | Surface-only, limited durability | Durable but inconsistent | Shallow and prone to wear |

| Customization | Quick design changes via CAD/CAM | Easy file adjustments | Manual, slow, less flexible | Requires new masks, slower adjustments |

| Waste & Safety | Minimal waste; dust extraction recommended | Minimal waste; fumes can be hazardous | No waste but labor-intensive | Hazardous chemicals, disposal required |

| Cost Efficiency | Higher initial investment, low per-part cost | Moderate setup cost, low per-part | Low tool cost, high labor cost | Low machine cost, high consumables |

| Best Use Case | Aerospace, automotive, marine, industrial parts | Fine 2D markings, logos, barcodes | Artistic, one-of-a-kind designs | Industrial coding and shallow markings |

Why Choose Us

High Precision & Efficiency

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Robust and Durable Design

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Intelligent Control Systems

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

Flexible Customization

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

Related Resources

How To Maintain CNC Routers

This article provides a comprehensive guide on how to maintain CNC routers, covering essential tasks, troubleshooting tips, upgrades, and best practices to ensure optimal performance and longevity.

What Is The Accuracy Of CNC Routers

This article is a comprehensive guide that explains the precision of CNC routers, the key factors affecting precision, expected performance, and how to improve machining results.

How to Choose the Right Router Bits for CNC Routers

This article explains how to select the right router bit for your CNC router, including cutter type, material, coating, and tip, to achieve precise, efficient, and durable cutting performance.

Stepper Motor VS Servo Motor

This article compares stepper motors and servo motors, detailing their working principles, performance characteristics, applications, and key differences in modern automation.

Frequently Asked Questions

How Much Do Composite CNC Routers Cost?

- 3-Axis CNC Routers: $3,000 – $10,000. Entry-level composite CNC routers handle basic cutting, engraving, and shaping on flat sheets. They are suitable for small-scale work in fiberglass, carbon fiber panels, or composite boards. While affordable, they lack the advanced flexibility needed for complex or curved geometries and may require frequent tool replacement due to composite abrasiveness.

- 4-Axis CNC Routers: $12,000 – $22,000. With a rotary axis, 4-axis CNC routers can machine cylindrical or angled surfaces, expanding their capability for composite tubes, aerospace components, or marine parts. Their higher cost reflects stronger construction, better spindles, and enhanced precision compared to 3-axis machines, making them more reliable for demanding materials.

- 5-Axis CNC Routers: $57,000 – $70,000. High-end 5-axis CNC routers offer full flexibility, cutting composites from nearly any angle with excellent precision. These are the machines used in industries like aerospace, automotive, and advanced manufacturing, where complex molds, aerodynamic parts, and multi-surface machining are required. Their cost reflects advanced engineering, servo-driven accuracy, and the ability to produce intricate parts in fewer setups.

- ATC (Automatic Tool Changer) CNC Routers: $8,000 – $25,000. CNC routers with automatic tool-changing systems are priced based on size, spindle type, and build quality rather than just axis count. They’re essential for working with composites where multiple operations—such as rough cutting, fine finishing, and drilling—must be performed in sequence. ATC reduces downtime and boosts production efficiency, making them valuable in professional and industrial shops.

How Do I Choose Composite CNC Routers?

- CNC Router Type and Number of Axes: A 3-axis CNC router is suitable for basic cutting, drilling, and profiling of flat composite sheets. For cylindrical parts or angled machining, a 4-axis CNC router adds rotational capability. A 5-axis machine is ideal for aerospace, marine, or automotive parts requiring complex curves, molds, and multi-surface machining. Your choice should match the level of geometric detail in your projects.

- Spindle Power and Cooling: Composite machining requires high spindle speeds and durable tooling to handle abrasive materials. Higher spindle power ensures smoother cutting through dense laminates. Cooling is also important—water-cooled spindles offer quieter, more stable operation for extended production runs, while air-cooled spindles provide simpler, low-maintenance setups.

- Workholding and Table System: Composites can be brittle and prone to vibration during machining. A vacuum table provides even, secure hold-down for sheets and panels, while specialized clamping fixtures are essential for irregular shapes. Proper workholding reduces tool wear and prevents edge chipping.

- Dust Extraction and Safety: Composite routing produces fine, abrasive dust that can damage machine components and pose health risks. A high-capacity dust collection system with HEPA filtration is critical. Some composites also release harmful particles, so proper ventilation and operator PPE are required.

- Tooling and ATC (Automatic Tool Changer): Composites quickly wear down router bits, making high-quality tooling a must. An ATC system saves time by automatically switching between roughing, finishing, and drilling tools, which is especially important in production environments where efficiency matters.

- Control System and Precision: Industries working with composites often require extremely tight tolerances. Look for CNC routers with rigid frames, servo-driven motors, and advanced control systems that ensure repeatability and smooth surface finishes. Software compatibility with CAD/CAM systems is also crucial for complex part programming.

- Budget and Support: Composite CNC routers range from $3,000 for basic models to $70,000 or more for advanced 5-axis machines. Beyond the purchase price, consider the cost of consumables (router bits, vacuum pumps, filters) and the availability of after-sales service, training, and warranties. Reliable support ensures long-term productivity.

What Are The Disadvantages Of CNC Routing Composite?

- Tool Wear and High Consumable Costs: Composites are extremely abrasive, especially carbon fiber and fiberglass. Router bits dull quickly, requiring frequent replacements. This drives up operational costs compared to machining wood or plastics, and using improper tooling can lead to premature breakage.

- Dust and Health Hazards: Machining composites generates fine, abrasive dust that can damage lungs if inhaled. Carbon fiber dust, in particular, poses health risks and requires HEPA-level extraction systems. Without proper dust collection and PPE, composite routing can be hazardous for operators.

- High Equipment Demands: Because of the toughness of composites, CNC routers need rigid frames, powerful spindles, and precise workholding. Entry-level machines may lack the durability to handle composites effectively, limiting them to more advanced or industrial-grade CNC routers.

- Surface Finish Challenges: Composites are prone to fraying, chipping, and delamination when cut. Achieving clean edges requires specialized bits, optimal feeds and speeds, and sometimes multiple finishing passes. Even with care, surface quality can be inconsistent.

- Noise and Vibration: Routing composites produces higher noise levels and vibration compared to softer materials. This not only affects operator comfort but can also reduce accuracy if the machine or workholding is not rigid enough.

- Heat Build-Up and Material Damage: If feeds and speeds are not set correctly, composites can overheat during routing. Excessive heat may cause resin burning, discoloration, or even weaken the material’s structural integrity. Cooling systems or air assist are often necessary.

- Cost of Setup and Operation: Working with composites requires not just the CNC router but also high-quality dust extraction, protective equipment, and durable tooling. These additional requirements raise both the upfront and ongoing costs of composite machining.

- Limited Flexibility with Certain Composites: Not all composites machine well with CNC routers. Some fiber-reinforced materials or resins may splinter or crack under cutting forces. In such cases, alternative methods like waterjet cutting may be more effective.

What Speed Is Required For CNC Routing Composite?

- Carbon Fiber Composites: Routing carbon fiber requires high spindle speeds, often in the range of 18,000–24,000 RPM. Feed rates should be matched to prevent excessive heat buildup, which can damage the resin matrix. Using diamond-coated or carbide tools is critical to withstand the abrasive fibers.

- Fiberglass and Glass-Reinforced Plastics (GRP): Like carbon fiber, fiberglass is abrasive and benefits from spindle speeds around 16,000–22,000 RPM. Too slow a speed risks fraying and rough edges, while too fast can overheat and dull the tool quickly. Proper dust extraction is essential to capture the fine, hazardous glass dust.

- Phenolic and Resin-Based Composites: These materials cut well at moderate to high spindle speeds, typically 15,000–20,000 RPM. Excessive heat can burn the resin, so maintaining a balance between speed and feed is important. Sharp tools and cooling air assist improve finish quality.

- Honeycomb Composites: Aluminum or Nomex honeycomb composites require slower cutting speeds compared to solid laminates, usually 10,000–15,000 RPM. This prevents tearing of the thin walls and ensures clean edges. Specialized tooling helps prevent the collapse of the honeycomb structure.

- Tool Size and Speed Relationship: Smaller router bits require higher spindle speeds (closer to 20,000–24,000 RPM) to maintain cutting efficiency, while larger bits operate better at slower speeds. Matching feed rates to spindle speed ensures proper chip evacuation and reduces tool loading.

- Cooling and Feed Rate Considerations: While most composite routing is done dry, using air blast or mist cooling at high speeds helps clear chips and reduces heat. Feed rates must be aggressive enough to move chips out of the cut zone but not so high that they cause delamination or tool chatter.

What Is The Life Expectancy Of Composite CNC Routers?

- Entry-Level CNC Routers (5–8 Years): Low-cost 3-axis CNC routers used for light composite work may last 5–8 years with proper maintenance. However, frequent machining of abrasive materials will wear down spindles, bearings, and guide rails faster. These machines are best suited for small shops or prototyping rather than heavy-duty production.

- Mid-Range Professional CNC Routers (8–12 Years): CNC routers designed for small to medium production facilities typically last 8–12 years. They feature stronger frames, higher-quality spindles, and improved dust management, allowing them to handle daily composite machining with fewer breakdowns. With consistent servicing, their useful life can extend well beyond a decade.

- Industrial CNC Routers (15–20+ Years): High-end 4-axis and 5-axis CNC routers built for aerospace, marine, and automotive industries can last 15–20 years or more. These machines are engineered for heavy, continuous use, with rigid frames, servo motors, and durable spindles. Many remain accurate and productive for decades if regularly maintained and updated.

- Spindles and Wear Components (2–5 Years): While the machine frame can last decades, high-wear parts like spindles, belts, and bearings require replacement every 2–5 years, depending on workload. Diamond-coated tooling helps extend cutting efficiency but still wears faster when machining composites.

- Impact of Maintenance and Environment: Dust is the biggest factor affecting composite CNC router life. Without strong dust collection and regular cleaning, abrasive particles damage moving parts and shorten the lifespan. Routine lubrication, calibration, and software updates ensure the CNC router stays accurate and reliable.

- Upgrade Potential: Even when the mechanical structure remains solid, outdated electronics or control systems can limit performance. Many industrial CNC routers stay in use for 20+ years thanks to retrofit upgrades in software, drives, and spindles.

What Training Is Required To Operate Composite CNC Routers?

- Basic CNC Operation and Machine Controls: Operators must learn how to start, stop, and control the CNC router safely. Training includes homing axes, setting workpiece zero points, loading toolpaths, and executing programs. Emergency stop procedures and safety protocols are emphasized to prevent accidents.

- CAD and CAM Software Skills: Since CNC routers rely on digital instructions, operators need proficiency in CAD (designing parts) and CAM (generating toolpaths). Training covers how to design complex shapes, select cutting strategies, and convert them into machine-ready G-code tailored for composites.

- Tooling and Bit Selection: Composites quickly wear down cutting tools, so operators must be trained to identify, select, and install the correct bits. Training includes understanding tool coatings (such as diamond-coated or carbide tools), choosing the right geometry, and monitoring tool condition for wear and damage.

- Feeds, Speeds, and Cutting Parameters: Routing composites requires precise settings to avoid delamination, chipping, or excessive heat. Operators must learn how to calculate appropriate spindle speeds and feed rates based on material type, thickness, and tool size, ensuring both efficiency and surface quality.

- Workholding and Fixturing: Composites are brittle and prone to vibration, so proper material hold-down is critical. Training covers using vacuum tables, clamps, and custom fixtures to prevent part movement, ensuring accuracy while minimizing stress on fragile materials.

- Dust Collection and Safety Protocols: Composite dust is hazardous to both operators and machines. Training emphasizes the use of high-efficiency dust extraction systems, personal protective equipment (PPE), and safe workshop practices to reduce exposure to carbon fiber and fiberglass particles.

- Maintenance and Troubleshooting: Operators need to know how to perform daily cleaning, lubrication, calibration, and inspection of spindles, belts, and bearings. Training also covers diagnosing issues like tool wear, edge fraying, or alignment errors, and taking corrective action to maintain productivity.

- Material Knowledge and Hazard Awareness: Different composites behave differently under cutting forces. Training includes understanding the properties of carbon fiber, fiberglass, phenolic, and honeycomb composites, along with their specific machining risks. Operators must also know which materials require extra caution due to hazardous dust or heat sensitivity.

What Problems Can Be Encountered When CNC Routing Composite?

- Rapid Tool Wear: Carbon fiber and fiberglass are highly abrasive, quickly dulling standard cutting bits. Even carbide tools can wear down fast, leading to poor surface quality and increased costs. Diamond-coated tooling is often required for extended performance.

- Fraying and Delamination: Composites are layered materials, and improper cutting parameters can cause the layers to separate (delamination) or the edges to fray. This results in rough surfaces, weak edges, and sometimes unusable parts. Correct feeds, speeds, and sharp tooling help minimize this issue.

- Excessive Dust Generation: Composite machining produces very fine dust that is not only abrasive but also hazardous to health. Carbon fiber dust, for example, can irritate lungs and skin. Without effective dust collection and personal protective equipment (PPE), both operators and machines are at risk.

- Overheating and Resin Burning: If the feed rate is too slow or the spindle speed too high, heat builds up, causing resin to burn or discolor. This weakens the composite and compromises aesthetics. Air blast or mist cooling is often needed to prevent overheating.

- Chipping and Edge Quality Issues: Sharp corners, drilled holes, and thin features are prone to chipping or cracking in composites. This is especially common with brittle laminates like phenolic resin boards. Specialized tooling and gradual passes are required for clean results.

- Vibration and Workholding Challenges: Composites can vibrate during cutting if not clamped properly. This leads to poor surface finish, tool chatter, and dimensional inaccuracies. Vacuum tables or custom jigs are often necessary to stabilize the material.

- Noise and Operator Discomfort: Routing composites is louder than machining wood or plastics, creating additional strain on operators. Prolonged cutting can require noise control systems or heavy-duty hearing protection.

- Machine Wear and Tear: The abrasive dust and fibers from composites can work their way into rails, bearings, and spindles, accelerating wear. Without frequent cleaning and maintenance, the lifespan of the machine is shortened.

- Material Waste and Cost: Composite materials like carbon fiber and aerospace laminates are expensive. Errors caused by poor tooling, programming, or fixturing can result in costly waste, making precision and careful setup especially important.

What Are The Maintenance Requirements for Composite CNC Routers?

- Dust and Chip Removal: Composites generate fine, abrasive dust that can damage moving parts and electronics. Daily cleaning with high-efficiency dust extraction, vacuums, or compressed air is essential. Operators should also check dust collection systems frequently, replacing filters to maintain suction power.

- Lubrication of Moving Components: Linear rails, ball screws, and bearings require regular lubrication to minimize friction and protect against wear from abrasive particles. Manufacturers typically provide lubrication schedules, and sticking to them prevents accuracy loss and premature failure.

- Spindle and Tool Care: Composite machining wears down spindles and router bits quickly. Operators should inspect spindles regularly for heat, vibration, or unusual noise, as these indicate wear. Tools should be cleaned, sharpened, or replaced often to maintain cut quality and avoid excessive stress on the machine.

- Calibration and Alignment: The constant vibration and stress of cutting composites can cause gradual misalignment. Regular calibration of gantries, spindles, and work tables ensures precision. Checking squareness, tool offsets, and zeroing accuracy should be part of a routine maintenance plan.

- Cooling and Air Systems: For CNC routers with water-cooled spindles, the coolant system must be inspected for leaks, blockages, and fluid quality. Air-assisted cooling systems also need filter changes and line inspections to prevent clogging and reduced performance.

- Inspection of Wear Parts: Belts, couplings, seals, and bearings wear faster when exposed to composite dust. Regular inspection and timely replacement of these consumables prevent unplanned breakdowns. Many operators keep spare parts on hand for quick swaps.

- Electrical and Control Systems: Dust can infiltrate electronics, leading to overheating or short circuits. Keeping enclosures sealed and filters clean protects sensitive components. Firmware and software should also be kept updated for stability and compatibility.

- Workholding Systems: Vacuum tables and clamps should be inspected for leaks or wear. Composite dust can clog vacuum ports, reducing hold-down power. Cleaning these systems ensures that materials stay secure during machining.