Product Introduction

Types of Aluminum CNC Routers

Material Routing Capability

| Metal Material Type | 1.5 kW | 2.2 kW | 3.0 kW | 3.2 kW | 3.5 kW | 4.5 kW | 5.5 kW | 6.0 kW | 7.5 kW | 9.0 kW |

|---|---|---|---|---|---|---|---|---|---|---|

| Aluminum Sheet/Plate | Very Light Engraving | Light Cutting | Light Cutting | Standard Cutting | Standard Cutting | High-Precision Cutting | Heavy-Duty Cutting | Heavy-Duty Cutting | Industrial Cutting | Industrial Cutting |

| Aluminum Composite Panel (ACP/ACM) | Surface grooving only | Surface Routing | Standard Cutting | Standard Cutting | High-Precision | High-Precision | Industrial Cutting | Industrial Cutting | Industrial Cutting | Industrial Cutting |

| Brass | Not Recommended | Light Engraving | Light Engraving | Light Cutting | Slow Cutting | Controlled Heavy Cuts | Heavy-Duty Cutting | Heavy-Duty | Industrial | Industrial |

| Copper | Not Recommended | Light Engraving | Light Engraving | Slow Routing | Controlled Routing | Heavy-Duty Cutting | Heavy-Duty | Industrial | Industrial | Industrial |

| Magnesium/Soft Alloy Metals | Not Recommended | Very Light Routing | Light Routing | Standard Routing | Standard Routing | Heavy-Duty | Heavy-Duty | Industrial | Industrial | Industrial |

| Casting Aluminum/Tooling Aluminum | Not Recommended | Not Recommended | Very Light | Very Light | Controlled Routing | Controlled Heavy Cuts | Heavy-Duty | Industrial | Industrial | Industrial |

| Stainless Steel | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported |

| Carbon Steel/Mild Steel | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported |

| Titanium/Hardened Steel | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported | Not Supported |

Compatible Materials

- 1050 Aluminum

- 1060 Aluminum

- 1070 Aluminum

- 1100 Aluminum

- 1200 Aluminum

- 2011 Aluminum

- 2014 Aluminum

- 2017 Aluminum

- 2024 Aluminum

- 3003 Aluminum

- 3004 Aluminum

- 3105 Aluminum

- 5005 Aluminum

- 5050 Aluminum

- 5052 Aluminum

- 5056 Aluminum

- 5083 Aluminum

- 5086 Aluminum

- 5154 Aluminum

- 5182 Aluminum

- 5251 Aluminum

- 5356 Aluminum

- 5454 Aluminum

- 5754 Aluminum

- 6013 Aluminum

- 6020 Aluminum

- 6060 Aluminum

- 6061 Aluminum

- 6063 Aluminum

- 6082 Aluminum

- 6101 Aluminum

- 6201 Aluminum

- 7005 Aluminum

- 7050 Aluminum

- 7072 Aluminum

- 7075 Aluminum

- 7108 Aluminum

- 7129 Aluminum

- Aluminum Composite Panels

- Cast Aluminum

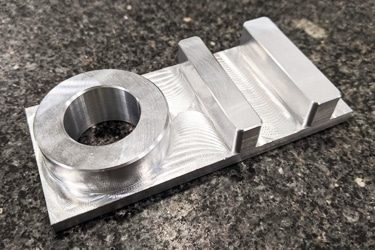

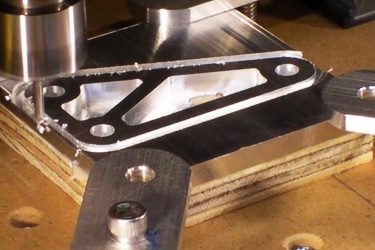

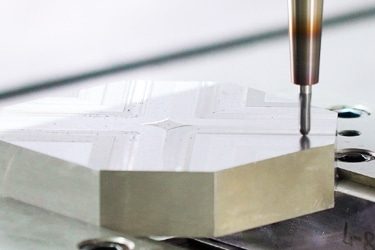

Application of Aluminum CNC Routers

Customer Testimonials

Comparison VS Other Engraving Technologies

| Comparison Item | Aluminum CNC Routing | Laser Engraving | Chemical Etching | EDM Engraving |

|---|---|---|---|---|

| Working Principle | Mechanical cutting with rotating end mills | Melting/vaporizing aluminum with laser heat | Acid/chemical removal of surface | Electrical discharge erodes material |

| Suitable Aluminum Grades | Most grades (1000–7000 series) | Limited to surface marking | Works on many grades, shallow only | Works on conductive grades (all aluminum) |

| Cutting Ability | Full-depth milling & profiling | Cannot cut aluminum effectively | No cutting | High-precision cutting, slower |

| Engraving Depth | Shallow to deep 3D engraving | Very shallow (surface only) | Very shallow | Medium to deep depending on settings |

| Precision Level | High accuracy & repeatability | Very fine detail on surface | Moderate | Extremely high precision |

| Edge Quality | Clean edges with proper tooling | Heat-affected zone, micro-burrs | Smooth but etched edges | Very smooth but slower |

| Heat Impact | Low with proper cooling | High thermal stress | None | Minimal thermal distortion |

| Material Removal Rate | Fast for routing & shaping | Very low | Low to medium | Low (slowest of all) |

| Ability for 3D Machining | Excellent (3D contours, pockets) | Not suitable | Not suitable | Excellent but slower |

| Tool Wear / Consumables | Tool wear depends on aluminum type | Laser optics wear over time | Chemicals require replacement | Electrodes wear down |

| Operating Cost | Low-medium | Medium (power + maintenance) | Medium-high (chemicals, disposal) | High (electrodes + energy) |

| Safety Requirements | Chips, noise, coolant | High heat, fumes | Chemical handling risks | Electrical discharge & dielectric fluid |

| Best Applications | Parts machining, molds, brackets, prototypes | Serial marking, logos | Serial numbers, surface textures | High-accuracy dies, molds |

| Production Volume Suitability | Ideal for small to mass production | Good for mass marking | Good for batch marking | Good for precision low-volume |

| Ideal Use Case | Versatile, fast aluminum shaping | Decorative or ID marking | Uniform shallow marking | Ultra-precision machining with tight tolerances |

Why Choose Us

High Precision & Efficiency

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Robust and Durable Design

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Intelligent Control Systems

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

Flexible Customization

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

Related Resources

How Do CNC Routers Work

This article explains the working principle of CNC routers, from the motion system and cutting tools to the software workflow, materials, precision, and actual machining principles.

How To Maintain CNC Routers

This article provides a comprehensive guide on how to maintain CNC routers, covering essential tasks, troubleshooting tips, upgrades, and best practices to ensure optimal performance and longevity.

What Is The Accuracy Of CNC Routers

This article is a comprehensive guide that explains the precision of CNC routers, the key factors affecting precision, expected performance, and how to improve machining results.

How to Choose the Right Router Bits for CNC Routers

This article explains how to select the right router bit for your CNC router, including cutter type, material, coating, and tip, to achieve precise, efficient, and durable cutting performance.

Frequently Asked Questions

What Is The Price Of Aluminum CNC Routers?

What Is The Working Range Of Aluminum CNC Routers?

- 400×400mm Small-Format Platforms: These compact work areas are ideal for high-precision aluminum machining, such as small brackets, heat sinks, electronic housings, molds, prototypes, and jewelry components. The smaller footprint provides better rigidity, reduced vibration, and improved accuracy. Because aluminum requires stable cutting conditions, this size works well for workshops that focus on fine-detail machining or batch production of small parts.

- 600×600mm Medium-Format Platforms: This size suits fabricators who need more flexibility for larger aluminum components while maintaining high precision. It is commonly used for signage, aluminum letters, mechanical parts, fixture plates, prototype housings, and structural pieces. With increased travel distance and stronger frames, machines in this range support deeper cuts, larger tooling operations, and improved chip evacuation. Many manufacturers prefer this format for a balance between throughput and accuracy.

- Customized Working Areas: Aluminum CNC routers can also be built according to customer requirements, such as 600×900mm, 1000×1000mm, 1200×1200mm, or even large-format 1300×2500mm and 1500×3000mm systems. Customized platforms allow manufacturers to match the machine to their specific workflows—such as machining large jigs, aerospace plates, automotive molds, battery trays, aluminum panels, or multi-component setups that require large clamping space. Customized solutions often come with reinforced gantries, upgraded spindles, and enhanced cooling and chip removal systems tailored to aluminum processing.

What Factors Affect The Price Of Aluminum CNC Routers?

- Machine Size and Working Area: Aluminum CNC routers are available in compact, medium, and large-format sizes, and larger working areas require stronger frames, extended guide rails, and heavier gantries. As the machine footprint increases, manufacturing complexity and material usage also rise, making size one of the biggest price determinants. Customized working ranges can further add to the overall cost.

- Spindle Type and Power: High-speed, high-torque spindles are essential for aluminum machining because the material requires sufficient cutting force, stable rotation, and efficient heat control. Machines equipped with powerful water-cooled spindles, automatic tool changers, or branded spindles from companies like HSD or HQD typically come at a higher price. Spindle performance has a direct correlation with cutting quality and productivity.

- Motion System and Mechanical Components: The CNC router’s movement accuracy depends on linear guides, ball screws, rack-and-pinion systems, and servo or stepper motors. Precision components with brands such as Hiwin, THK, or Yaskawa increase the machine’s stability and enhance long-term performance. More advanced or high-precision motion systems naturally raise costs but deliver better accuracy for aluminum processing.

- Machine Structure and Build Quality: Aluminum CNC routers require rigid frames, reinforced gantries, and vibration-resistant mechanical designs to maintain accuracy during high-speed cutting. Machines with heavy-duty steel frames, stress-relieved bases, and welded structures typically cost more but ensure long-term durability. Additional enhancements like dust-proof covers, chip guards, and water mist cooling systems also contribute to pricing.

- Control System and Software: Controllers like Syntec, NcStudio, Mach3/4, or industrial-grade systems from OSAI and Siemens vary in sophistication and cost. Higher-end controllers offer smoother motion, better toolpath handling, and improved reliability, which adds to the price, especially for aluminum-specific operations.

- Additional Features and Custom Options: Elements like vacuum tables, ATC magazines, probe systems, enclosure designs, lubrication units, and advanced cooling systems can raise the total cost. Each upgrade enhances functionality or precision, making them valuable for specific applications.

What Is The Accuracy Of Aluminum CNC Routers?

- Positioning Accuracy (0.02–0.05 mm): Most aluminum CNC routers feature high-quality linear guides, ball screws, or rack-and-pinion systems that ensure stable and precise movement. These components enable the machine to reach target positions with minimal deviation. For users machining detailed aluminum parts—such as brackets, optical mounts, housings, or precision plates—this level of accuracy provides consistent, professional-grade results. Machines built with branded components like Hiwin or THK can achieve even tighter tolerances in controlled environments.

- Repeatability Accuracy (0.01–0.03 mm): Repeatability refers to the machine’s ability to return to the same position after multiple movements. Strong machine frames, servo-driven systems, and rigid gantry designs help aluminum CNC routers maintain excellent repeatability. This is essential for batch production, where multiple identical aluminum parts must meet strict dimensional requirements. High-end servo systems further improve repeatability, making them ideal for tooling, aerospace components, and prototyping tasks.

- Machining Accuracy (0.02–0.08 mm depending on material and tooling): Actual cutting accuracy varies based on toolpath strategy, spindle rigidity, feed rates, and material hardness. Aluminum requires stable chip evacuation and proper cooling to maintain surface smoothness and dimensional accuracy. Water-mist cooling systems, sharp carbide tools, and optimized spindle speeds help minimize tool deflection and thermal expansion. When configured correctly, aluminum CNC routers can achieve tight tolerances suitable for mechanical engineering and industrial fabrication.

- Influencing Factors: Machine structure, ambient temperature, vibration control, and maintenance practices all play a role in achieving high accuracy. Reinforced frames and stress-relieved bases reduce distortion, while high-speed spindles maintain steady cutting performance. Proper calibration and routine care further support long-term precision.

How To Choose An Aluminum CNC Router?

- Define Your Workpiece Size and Application Needs: Start by identifying the largest aluminum parts you plan to machine. Compact sizes like 400×400 mm suit small brackets, electronic enclosures, and precision prototypes, while medium formats such as 600×600 mm handle signage letters, fixture plates, and mechanical components. If you need to process large panels, molds, or multi-part setups, customized working areas provide greater flexibility.

- Evaluate Machine Rigidity and Frame Structure: Aluminum cutting requires a stable, vibration-resistant frame to ensure dimensional accuracy. Choose CNC routers built with heavy-duty steel bases, reinforced gantries, and stress-relieved structures. A rigid machine reduces chatter, improves surface finish, and enhances tool life. Lightweight frames may work for wood, but are insufficient for aluminum’s hardness and cutting loads.

- Select the Right Spindle Power and Cooling System: High-speed spindles with strong torque are essential for smooth aluminum machining. Look for 2.2 kW to 5.5 kW spindles, depending on the depth of cut and tool diameter. Water-cooled spindles deliver better thermal stability, while mist-cooling or air-blast systems help maintain clean chips and prevent tool overheating. ATC spindles are useful for complex jobs requiring frequent tool changes.

- Check Motion Components and Drive Systems: Linear guides, ball screws, servo motors, and precision gear systems directly affect accuracy. Machines equipped with branded components like Hiwin, THK, Yaskawa, or Leadshine offer higher reliability. For aluminum applications requiring fine details or tight tolerances, servo-driven systems provide smoother motion and higher repeatability than steppers.

- Consider the Controller and Software Compatibility: Industrial controllers such as Syntec, OSAI, Siemens, or Mach4 offer stable performance and smoother toolpaths. Ensure the controller supports advanced milling strategies, 3D machining, and compatibility with your CAD/CAM workflows.

- Review Optional Features and Safety Enhancements: Vacuum tables, enclosures, lubrication units, probing systems, and dust or chip extraction improve efficiency and cleanliness. These upgrades are especially beneficial in long-term aluminum machining.

Is It Safe To Use Aluminum CNC Routers?

- Machine Structure and Built-In Safety Features: Most aluminum CNC routers use heavy-duty steel frames, enclosed gantries, and stable worktables that minimize vibration and prevent unexpected movement. Many machines include limit switches, emergency stop buttons, spindle overload protection, and controller-based safety interlocks. These features ensure the machine stops quickly during abnormal conditions, reducing risks associated with tool breakage or mechanical failure.

- Chip Control and Cooling Systems: Aluminum machining generates sharp chips and fine dust that require proper extraction and cooling. CNC routers equipped with air blast, mist cooling, or vacuum extraction systems help prevent chip buildup, reduce heat, and maintain a clean working environment. Removing chips promptly improves visibility and prevents them from becoming a slipping or fire hazard.

- Operator Training and Setup Procedures: Safe CNC use depends heavily on the operator’s understanding of feed rates, toolpath strategies, and tooling selection. Incorrect programming or using worn tools can lead to tool failure or poor cutting performance. Well-trained operators monitor tool conditions, verify fixtures, and ensure the machine is properly calibrated before starting a job.

- Workpiece Clamping and Stability: Aluminum sheets, plates, and blocks must be firmly secured using T-slot clamps, vises, or vacuum tables. Loose materials can shift during machining and cause tool breakage or machine damage. Proper fixturing is essential for preventing unexpected movement and ensuring both operator safety and machining accuracy.

- Environmental and Electrical Safety: CNC routers should be used in well-ventilated areas with sufficient lighting to maintain visibility. Machines must be grounded properly, and electrical connections should be inspected regularly to avoid hazards. Safety enclosures or shields provide extra protection from flying chips, especially during high-speed milling.

What PPE Is Needed To Operate Aluminum CNC Routers?

- Safety Glasses or Full-Face Shields: Eye protection is the most critical PPE when machining aluminum. High-speed cutting generates sharp chips that can eject from the workpiece, especially during deep milling or slotting. Safety glasses with side shields protect against debris, while full-face shields offer added protection from larger fragments, coolant splash, or unexpected chip lift.

- Hearing Protection: Aluminum cutting often produces significant noise due to spindle speed, chip impact, and vacuum extraction systems. Foam earplugs or earmuff-style hearing protectors help reduce exposure to harmful sound levels. Prolonged operation without hearing protection can lead to fatigue or long-term hearing damage, particularly in workshops using high-powered spindles.

- Cut-Resistant Gloves (Used Only During Setup): While gloves should never be worn when the machine is running, cut-resistant gloves are useful during part handling, tool installation, or chip cleanup when the spindle is stopped. These gloves protect against sharp aluminum edges, burrs, and hot chips. Operators must remove gloves before touching controls or working near moving components to avoid entanglement risks.

- Protective Clothing and Aprons: Workwear made of durable, close-fitting material helps prevent loose fabric from getting caught in the machine. Heavy aprons or machinist jackets offer additional impact and heat protection. Avoid long sleeves, jewelry, or anything that can snag during machine operation.

- Respiratory Protection (If Needed): Most aluminum CNC routers use chip evacuation, but fine dust may still be generated during high-speed finishing passes. Dust masks or respirators are recommended in enclosed or poorly ventilated environments. When mist cooling systems are used, proper ventilation ensures clean air quality.

- Steel-Toe Safety Shoes: Foot protection helps guard against dropped aluminum plates, heavy fixtures, or clamps. Anti-slip soles improve stability when working around coolant or chip-covered floors.

What Are The Environmental Requirements For Aluminum CNC Routers?

- Stable Temperature and Humidity Control: Temperature fluctuations can affect machine accuracy by causing thermal expansion in the frame, spindle, and workpiece. Ideally, the workshop should maintain a temperature between 15℃ and 30℃, with minimal daily variation. Humidity levels should remain moderate—typically 40–70%—to prevent corrosion on metal parts and electrical components. Extreme temperature swings can reduce precision and shorten machine lifespan.

- Adequate Ventilation and Airflow: Although aluminum CNC routers generate chips rather than heavy smoke, proper ventilation is essential to manage fine dust, mist, cooling residue, or oil vapors from lubrication systems. Workshops should have exhaust fans, filtration systems, or air circulation units to maintain clean airflow. Good ventilation also improves operator comfort and supports safer machining conditions.

- Clean, Dust-Free Workspace: Dust and debris can interfere with linear guides, ball screws, and sensor systems. Maintaining a clean environment ensures smoother machine movement and prevents premature wear. Chip extraction systems, shop vacuums, and routine cleaning help maintain performance. By keeping aluminum chips under control, the workshop reduces slipping hazards and protects mechanical components.

- Solid, Level Flooring: A strong, vibration-resistant floor is crucial for aluminum CNC routing, as uneven surfaces can cause machine misalignment or unstable cutting conditions. Concrete floors are preferred because they support the machine’s weight and minimize vibration. Routing aluminum at high speeds requires a stable base to maintain accuracy and protect structural components.

- Proper Electrical Supply and Grounding: CNC routers depend on stable power to ensure consistent spindle speed and drive system performance. Workshops should provide dedicated circuits, proper grounding, and surge protection. Unstable voltage can cause controller errors or damage sensitive electronics.

- Sufficient Space for Operation and Maintenance: Adequate clearance around the machine allows for safe loading of aluminum plates, smooth operator movement, and easy access for cleaning or repairs. Crowded spaces increase the risk of accidents and limit workflow efficiency.