Advantages and Disadvantages of Oscillating Knife Cutting Machines

Oscillating knife cutting machines have become a staple in industries that demand precision cutting—packaging, textiles, signage, automotive, and more. These machines use a rapidly vibrating blade to slice through a wide range of soft to semi-rigid materials with high accuracy and minimal waste. Unlike rotary or drag knife cutting machines, oscillating knives rely on up-and-down motion, allowing for cleaner cuts on complex shapes and tough materials like foam, leather, composites, and corrugated board.

As automation and digital fabrication continue to evolve, oscillating knife cutting systems are gaining traction for their speed, adaptability, and integration with digital workflows. Their growing popularity is driven by their ability to deliver consistent results across customized production runs, often with little need for post-processing.

However, no machine is without its limitations. While oscillating knife cutting machines offer clear advantages in terms of precision and versatility, they also come with drawbacks, such as higher maintenance needs and limitations on material thickness and hardness.

This article breaks down the key advantages and disadvantages of oscillating knife cutting machines, helping businesses, manufacturers, and designers assess whether this cutting technology fits their needs. Understanding both the benefits and the trade-offs is crucial for making informed decisions in a competitive production environment.

Table of Contents

What Are Oscillating Knife Cutting Machines?

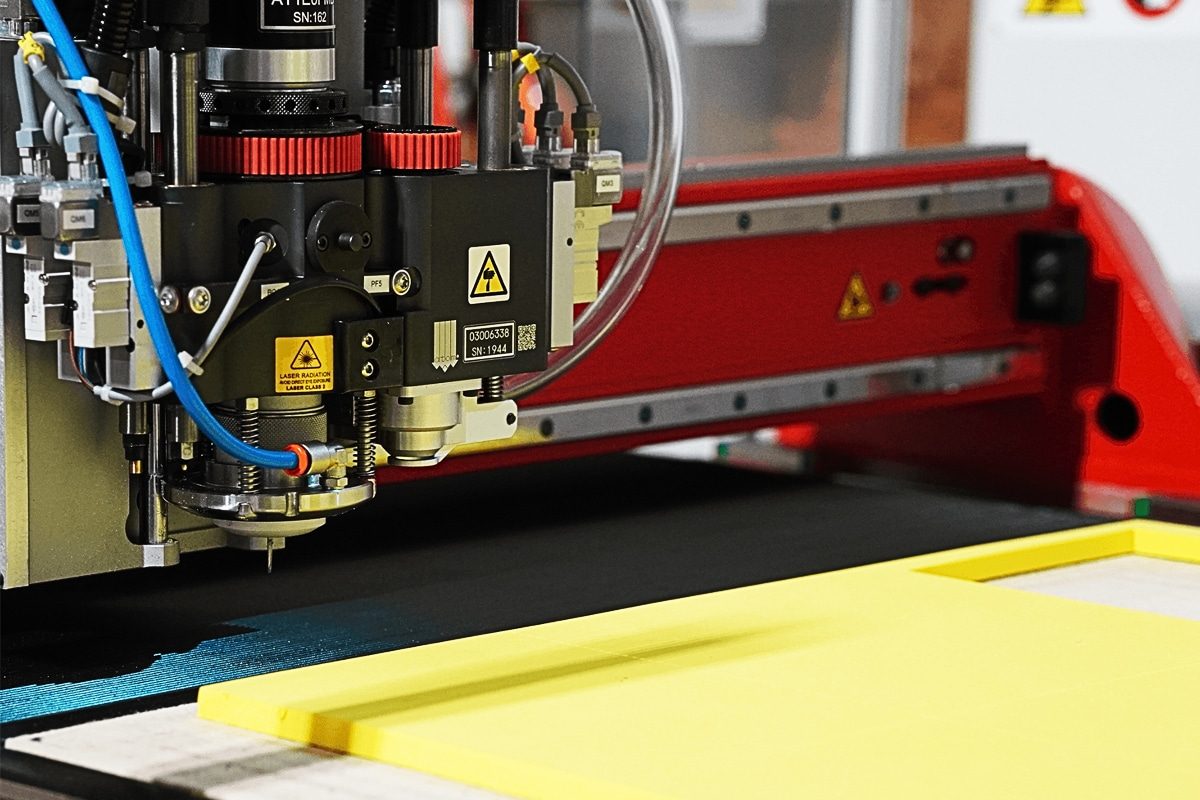

An oscillating knife cutting machine is a computer-controlled cutting system that uses a blade that moves rapidly up and down (oscillates) to slice through materials with high precision. Unlike rotary or drag knife cutting machines, which rely on continuous or dragged motion, the oscillating knife’s vibration—typically at thousands of strokes per minute—delivers clean, controlled cuts with minimal distortion, especially on flexible, soft, or layered materials.

These machines are commonly part of CNC (Computer Numerical Control) systems or digital cutting tables. They’re often integrated with CAD software, allowing users to import digital patterns and execute complex designs automatically. The blade can follow intricate paths, angles, and curves with exceptional accuracy, making it suitable for materials that are difficult to cut cleanly with traditional methods.

Oscillating knife cutting machines are widely used in industries like packaging, textiles, automotive interiors, aerospace composites, signage, leather goods, and foam fabrication. They are capable of handling a wide range of substrates, including cardboard, foam board, vinyl, gasket material, rubber, cork, felt, corrugated plastic, and more.

Machines can come in various configurations—from standalone units for small-scale jobs to large-format flatbed systems for industrial production. Many models allow for interchangeable tools, such as creasing wheels, pens, and laser pointers, further expanding their versatility.

In short, an oscillating knife cutting machine is a flexible, high-precision tool designed to handle complex cutting jobs with speed and efficiency. Its strength lies in its adaptability to different materials and its ability to deliver consistent, high-quality results, especially in environments that demand customized, short-run, or prototyping work.

Advantages of Oscillating Knife Cutting Machines

Oscillating knife cutting machines have rapidly become a go-to solution for precision cutting in industries ranging from packaging and signage to automotive, apparel, and aerospace. Their unique design—centered around a rapidly vibrating blade—offers a combination of speed, control, and material flexibility that few other cutting methods can match.

High Precision Cutting

One of the core advantages of oscillating knife technology is its ability to deliver exceptionally accurate and repeatable cuts. The oscillating blade moves vertically at high frequencies (often thousands of strokes per minute), allowing it to follow intricate paths and sharp corners with minimal deviation. This level of precision is critical in industries where even small errors can result in product failure or high rejection rates. Whether cutting printed packaging, technical textiles, or composite parts, these machines consistently produce clean, burr-free edges.

Versatility Across Materials

Oscillating knife cutting machines can process an impressive range of materials, from soft foams, rubber, and felt to tougher substrates like leather, fiberboard, corrugated plastic, and composites. This multi-material capability means that a single machine can handle jobs that would otherwise require multiple specialized cutting machines. Manufacturers save on equipment costs and floor space while gaining the flexibility to switch between different production types with minimal downtime.

Cold Cutting Technology

Unlike laser cutting machines or hot knife tools that use heat to slice through materials, oscillating knife machines operate using a cold mechanical process. This eliminates the risk of thermal damage—such as charring, discoloration, melting, or warping—making them ideal for heat-sensitive materials like foam board, vinyl, or fabric. Cold cutting also improves workplace safety by removing fire risks and reducing the need for heat shielding or ventilation.

Minimal Material Waste

With precise blade control and optimized cutting paths, oscillating knife cutting machines significantly reduce material waste. Integrated nesting software maximizes material usage by arranging patterns tightly together, while the clean cutting motion prevents frayed edges or misaligned cuts that often lead to scrapping. Over time, these savings on material waste can result in considerable cost reductions for high-volume operations.

Reduced Tool Wear

Unlike rotary or drag-based systems that experience continuous friction, the up-and-down oscillating motion places less wear on the blade and machine components. The result is a longer lifespan for cutting tools and fewer interruptions for blade replacement or recalibration. Some machines also offer automatic blade calibration and wear compensation features, further extending tool longevity.

Fast Turnaround Time

Oscillating knife machines are built for speed. Their rapid cutting action, coupled with CNC automation and fast material changeovers, allows them to process large orders or short-run custom jobs in minimal time. This makes them especially valuable in industries with tight deadlines, such as prototyping, custom packaging, or on-demand apparel production.

Clean Working Environment

Because these machines don’t generate heat, fumes, or excessive dust, they contribute to a much cleaner workspace. Operators aren’t exposed to smoke, burnt residues, or fine particulate matter that often results from laser or abrasive cutting methods. This reduces the need for intensive cleanup, improves air quality, and simplifies compliance with workplace safety standards.

Digital Integration and Automation

Modern oscillating knife cutting machines are fully compatible with digital design and manufacturing systems. They can import vector files from CAD or graphics software and execute cuts with zero manual intervention. Many machines also feature barcode scanning, automatic material recognition, job queueing, and cloud-based monitoring, making them a smart fit for Industry 4.0 environments and digitally connected production lines.

No Material Distortion

Because the cutting process is vertical and not dragged or rolled, the machine applies very little lateral force to the material. This minimizes distortion, stretching, or shifting—common problems with drag knife systems, especially when working with delicate or elastic materials like foam rubber or fabric. This is crucial for precision jobs where maintaining the original material dimensions and integrity is essential.

Multi-Tool Functionality

Many oscillating knife systems support tool-changing heads, allowing users to switch between different functions—such as creasing, perforating, plotting, or kiss-cutting—without changing machines. This built-in versatility reduces the need for secondary processing, increases production efficiency, and enables more complex jobs to be completed in a single workflow.

In today’s fast-paced, high-mix production environments, oscillating knife cutting machines offer a compelling mix of speed, accuracy, material flexibility, and digital control. Their ability to handle a wide range of materials without heat, maintain sharp tolerances, and integrate easily with automated systems makes them a powerful asset for any manufacturer looking to improve quality while reducing lead times and costs. Whether used for prototyping, custom production, or full-scale manufacturing, these machines provide a scalable, efficient cutting solution with numerous operational benefits.

Disadvantages of Oscillating Knife Cutting Machines

While oscillating knife cutting machines offer numerous benefits in precision, versatility, and automation, they are not without their limitations. Understanding the downsides is critical for companies evaluating whether this technology is the right fit for their specific production needs. Some drawbacks stem from the mechanical nature of the oscillating blade, while others relate to operational requirements and cost considerations.

Limited Cutting Thickness

Oscillating knife cutting machines are primarily designed for soft to semi-rigid materials. While they can handle multilayer stacks or thick foam up to a certain point, they struggle with very thick or dense materials. If the blade is too short or not rigid enough, it can result in incomplete cuts or blade deflection. This makes them less suitable for heavy-duty applications where thick, hard materials are the norm.

Slower Than High-Power Alternatives

Compared to laser or waterjet cutting systems, oscillating knife machines can be slower, especially on dense or fibrous materials. The mechanical up-and-down motion, while precise, is not as fast as the continuous beam of a laser or the high-pressure stream of a waterjet. For high-volume operations that prioritize speed over versatility, this can be a bottleneck.

Maintenance of Blades

Although oscillating knife blades wear out more slowly than rotary or drag knives, they still require regular inspection, sharpening, or replacement. Over time, dull blades can cause fraying, uneven edges, or imprecise cuts. Additionally, blade maintenance adds to operational downtime if not managed efficiently with proper scheduling or automatic alerts.

Noise Levels

The high-frequency vibration of the blade creates noticeable noise during operation, especially at higher speeds or when cutting tougher materials. In a production setting with multiple machines, this can lead to elevated noise levels, requiring hearing protection and additional sound insulation measures in the workspace.

Tool Limitations for Certain Geometries

While excellent at contour cutting and intricate patterns, oscillating knife blades have limitations when it comes to extremely small internal radii, sharp corners, or micro-details. The physical size and motion of the blade mean it cannot achieve the same level of geometric freedom as a laser beam or CNC router in some applications.

Higher Initial Investment Than Manual Cutting

Although less expensive than some high-end automated cutting machines, oscillating knife machines still require a significant upfront investment compared to manual tools like scissors, utility knives, or hand-operated cutting machines. For small operations or hobby-level users, the cost may not be justifiable without sufficient volume or specialized needs.

Operator Training Required

Despite their digital integration, these machines are not plug-and-play. Operators must be trained to use the software interface, handle material setups, adjust tool parameters, and perform maintenance tasks. Lack of training can result in tool damage, poor-quality cuts, or inefficient workflows.

Vibration Management

The high-speed oscillation of the cutting head introduces vibration, which—if not properly dampened—can affect cutting accuracy or cause wear on machine components over time. Manufacturers typically address this with precision-built frames and dampening systems, but maintaining this performance may require additional adjustments or part replacements.

Limited Suitability for Hard-Surface Cutting

Oscillating knife cutting machines are not designed to cut metals, glass, stone, or other rigid surfaces. Attempting to do so can damage the blade or the machine. For these materials, alternative technologies such as waterjet or laser cutting are more appropriate.

Regular Calibration and Software Updates

To maintain optimal performance and cutting precision, these machines require routine calibration, particularly after long production runs or blade changes. Additionally, as they rely on digital control systems, software updates may be necessary to ensure compatibility with design files, improve performance, or fix bugs. These tasks, while manageable, add to the machine’s overall maintenance workload.

Oscillating knife cutting machines are powerful tools for precision cutting across a wide range of materials, but they come with trade-offs. From physical limitations—like thickness constraints and speed—to operational considerations such as training, noise, and maintenance, these factors can impact their suitability for certain production environments. Businesses considering this technology must weigh the performance benefits against these drawbacks to determine whether it aligns with their specific production goals, budget, and material requirements. In some cases, the precision and versatility may outweigh the limitations; in others, a different cutting method may offer a better return on investment.

Applications of Oscillating Knife Cutting Machines

Oscillating knife cutting machines are valued for their precision, flexibility, and compatibility with a wide range of materials. These characteristics have made them essential tools in many industries, especially those that demand clean cuts, intricate shapes, and efficient short-run or custom production. Their ability to handle soft and semi-rigid materials with minimal waste and high accuracy allows manufacturers to streamline operations, reduce manual labor, and improve product quality. Below are some of the key industries where oscillating knife cutting machines play a critical role:

Signage and Display Industry

In the signage world, clean edges and accurate cuts are non-negotiable. Oscillating knife cutting machines are ideal for cutting vinyl, foam board, corrugated plastic, PVC, and cardboard—materials commonly used for indoor and outdoor signs, displays, POP (point-of-purchase) materials, and exhibition graphics. The machines can handle complex designs, lettering, and layered pieces without fraying or tearing, allowing for rapid prototyping and on-demand customization.

Automotive Sector

In automotive manufacturing, oscillating knife machines are used to cut interior components such as carpets, insulation foams, headliners, gaskets, and soundproofing materials. Precision is key for these parts to fit seamlessly into vehicle interiors. The machines also support multi-layer cutting, which increases throughput and ensures consistent results across batches.

Footwear and Leather Goods

The footwear and leather industries benefit from the machines’ ability to cleanly slice through leather, synthetic leather, EVA foam, and textile layers. Oscillating knife cutting machines ensure precise cuts for shoe uppers, insoles, and design patterns while reducing material waste, especially important when working with high-value materials. They also support nesting software to maximize hide usage, a major cost factor in leather production.

Packaging Industry

Oscillating knife cutting machines are widely used to produce corrugated boxes, folding cartons, foam inserts, protective packaging, and custom die-less packaging prototypes. Their digital control allows quick changes in design without requiring physical dies or tools, reducing turnaround time for short runs and customized packaging solutions.

Apparel and Fashion

In the apparel and fashion industry, these machines are ideal for cutting woven fabrics, nonwovens, technical textiles, and multilayer garments. Designers can move from digital patterns to final-cut fabric quickly, making them excellent for prototyping, sample production, and small batch manufacturing. Since the process doesn’t involve heat, there’s no risk of fabric scorching or distortion.

Gasket Manufacturing

Gaskets require extremely precise cuts to ensure proper sealing performance. Oscillating knife cutting machines handle rubber, cork, graphite composites, felt, and other gasket materials with ease. Their ability to produce clean, accurate contours without deforming the material makes them indispensable in the production of gaskets for engines, pumps, and industrial machinery.

Furniture Production

In the furniture industry, these machines are used to cut upholstery materials such as foam, fabric, felt, and vinyl. Whether for cushions, backrests, or insulation layers, oscillating knife cutting machines help manufacturers reduce labor, speed up production, and ensure consistency in part sizes, critical for mass assembly.

Composite Processing

Advanced composites like carbon fiber, fiberglass, and aramid are used in aerospace, sporting goods, and high-performance applications. Oscillating knife cutting machines can process prepreg sheets, honeycomb panels, and layered composites without fraying or delamination. Their cold-cutting nature ensures the material properties aren’t compromised during the process, which is vital in structural or load-bearing applications.

Oscillating knife cutting machines have become essential in industries where material precision, flexibility, and automation are key. From signage and packaging to automotive interiors and high-performance composites, their broad application range speaks to their reliability and adaptability. As industries move toward shorter production cycles, customization, and smart manufacturing, these machines are poised to play an even bigger role in shaping efficient, high-quality workflows.

Key Considerations When Choosing an Oscillating Knife Cutting Machine

Selecting the right oscillating knife cutting machine isn’t just about picking a tool—it’s about choosing a system that fits your materials, production volume, workflow, and long-term goals. With many models and configurations available on the market, understanding the key factors that impact performance, efficiency, and return on investment is crucial. Below are the most important considerations to evaluate before purchasing or upgrading an oscillating knife cutting system.

Material Compatibility

Not all oscillating knife machines are designed to handle every material. Some models excel with soft materials like foam, felt, and textiles, while others are optimized for stiffer substrates like rubber, leather, or corrugated board. It’s important to confirm whether the machine supports your primary materials, both in terms of blade strength and motion control. If your business involves cutting a wide variety of materials, a machine with versatile cutting capabilities and adjustable blade settings is essential.

Cutting Thickness Range

The machine’s cutting depth must match the thickness of the materials you regularly work with. Each machine has a maximum cutting height, which is typically influenced by the blade length, drive power, and tool head design. For applications involving layered materials, dense foams, or thicker substrates, ensure the machine can handle the full stack height cleanly and without deflection. Underestimating this can lead to poor-quality cuts and increased rework.

Tooling Options

Many oscillating knife cutting machines come with modular tool heads or multi-tool configurations, allowing users to perform multiple tasks—cutting, creasing, perforating, kiss-cutting, or plotting—in one setup. Consider whether you need interchangeable tools, automatic tool changers, or specialty blades for your specific applications. The more flexible the tooling system, the more future-proof and versatile the machine becomes.

Drive System

The type and quality of the drive system directly affect cutting speed, accuracy, and vibration control. Machines can be belt-driven, rack-and-pinion, or linear motor-driven. Higher-end systems offer better repeatability and smoother motion, especially on complex paths or tight corners. For high-precision or high-speed applications, investing in a robust and responsive drive system is worth the added cost.

Software Integration

A powerful software interface is just as important as the hardware. Look for machines that integrate seamlessly with your design tools—such as CAD/CAM, Illustrator, or CorelDRAW—and support features like nesting, job queuing, variable data input, and barcode recognition. Cloud connectivity, remote diagnostics, and real-time monitoring are additional features that can boost efficiency in digital production environments.

Work Area Size

The dimensions of the cutting bed dictate the maximum sheet or roll size the machine can process. Choosing the right work area size depends on your material format and job types. Oversizing can be unnecessarily expensive, while undersizing can limit productivity and require frequent material repositioning. Consider your largest expected job and choose a work area that accommodates it without compromise.

Support and Training

Even the best machine won’t deliver results without proper setup and operator skill. Reliable customer support, onboarding assistance, and ongoing training resources are crucial, especially for businesses adopting digital cutting for the first time. Check whether the vendor provides technical support, installation services, manuals, video tutorials, and live training sessions. Local availability of parts and service technicians is also a major plus.

Maintenance Requirements

All cutting machines require upkeep, but maintenance needs can vary significantly between models. Look into how often blades need replacing, how accessible the tool heads are for cleaning and servicing, and whether the machine offers self-diagnostics or maintenance alerts. Machines that are easy to maintain will have less downtime and lower total cost of ownership over time.

Choosing an oscillating knife cutting machine is a strategic investment that impacts your production quality, workflow efficiency, and long-term adaptability. Material compatibility, cutting depth, tool flexibility, and software integration are core factors, but they must be weighed alongside practical concerns like work area size, maintenance, and support. By carefully assessing these considerations based on your specific operational needs, you can select a machine that delivers consistent performance, minimizes waste, and supports your business as it grows and diversifies.

Maintenance and Operational Tips

To ensure optimal performance and extend the life of an oscillating knife cutting machine, consistent maintenance and smart operational practices are essential. These machines are built for precision, but their performance can quickly degrade without proper care. From mechanical upkeep to operator training, routine checks and procedures help prevent downtime, reduce waste, and maintain cutting accuracy over time. Below are the most important maintenance and operational tips to keep your machine running at its best.

Clean the Blade Area Regularly

Dust, debris, and material residue can accumulate around the blade and tool head, especially when cutting fibrous or layered materials like foam, felt, or cardboard. Regular cleaning prevents buildup that can interfere with blade movement, reduce cutting quality, or cause premature wear. A daily wipe-down and deeper weekly cleaning with compressed air or a soft brush can go a long way toward ensuring consistent performance.

Replace Blades on Schedule

Even the most durable oscillating blades dull over time. Dull blades lead to frayed edges, incomplete cuts, and increased load on the oscillation motor. Establish a replacement schedule based on your material type and cutting frequency. Many operators replace blades too late, chasing poor cut quality with software adjustments when a simple blade change would solve the problem.

Check Oscillation Motor Health

The motor that drives the up-and-down blade motion is a critical component. Signs of wear—such as increased noise, slower oscillation speed, or inconsistent cuts—should be addressed immediately. Monitoring motor performance can help identify early-stage failures. Some machines include built-in diagnostics or allow you to set alerts for motor maintenance intervals.

Calibrate Sensors Periodically

Most oscillating knife cutting machines rely on sensors for depth control, tool positioning, and material recognition. Periodic calibration ensures that the sensors maintain their accuracy, especially after tool changes, mechanical shocks, or extended use. Incorrect calibration can lead to inconsistent cutting depths, tool collisions, or wasted materials.

Keep Software Updated

Machine performance isn’t just about hardware—software plays a huge role. Manufacturers frequently release firmware and software updates that fix bugs, improve speed, expand compatibility with file formats, or enhance nesting and optimization algorithms. Regular updates ensure your machine runs efficiently and remains compatible with modern design workflows.

Inspect Clamping and Feeding Systems

A stable material feed is essential for clean, accurate cuts. Loose clamps or misaligned feeding rollers can cause shifting, wrinkling, or distortion during the cut. Make it a habit to inspect clamping systems, tension bars, and conveyor belts. Lubricate moving parts as needed and ensure materials are loaded evenly and securely.

Train Operators Continuously

A well-maintained machine still depends on skilled operators. Continuous training ensures that your team knows how to adjust settings, detect problems early, and use advanced features efficiently. Provide refresher training on safety, software use, material handling, and troubleshooting. The better the operator, the more value you get from your equipment.

Maintaining an oscillating knife cutting machine isn’t overly complex, but it does require discipline and consistency. Routine cleaning, scheduled blade changes, sensor calibration, and software updates all contribute to better performance and longer machine life. Just as important is keeping operators trained and systems inspected. By treating maintenance as a proactive investment rather than a reactive chore, businesses can ensure their machines deliver clean, precise cuts day after day, while minimizing unexpected downtime and costly repairs.

Summary

Oscillating knife cutting machines have earned their place in modern manufacturing thanks to their precision, versatility, and adaptability across industries. From signage and packaging to automotive interiors and leather goods, these machines offer clean, accurate cuts on a wide range of soft and semi-rigid materials. Their cold cutting process reduces material distortion, waste, and safety risks, while features like digital integration, multi-tool capability, and minimal maintenance downtime make them ideal for short runs, custom orders, and smart production workflows.

However, no technology is without trade-offs. Oscillating knife cutting machines are generally slower than high-power systems like lasers or waterjets and face limitations with very thick or hard materials. They require routine maintenance, software updates, and proper operator training to perform at their best. Initial investment costs and the need for vibration and noise management are also important considerations.

Choosing the right machine depends on matching capabilities to specific production needs, factoring in material types, cutting volume, tooling flexibility, and operational support. When properly maintained and used in the right applications, oscillating knife cutting machines deliver significant value through consistent performance, clean cuts, and workflow efficiency. For businesses prioritizing precision, material range, and customization, they remain a smart and strategic solution.

Get Oscillating Knife Cutting Solutions

When precision, versatility, and digital control matter, investing in the right oscillating knife cutting system can transform your production process. Whether you’re in packaging, signage, textiles, automotive, or custom fabrication, choosing a reliable machine from a proven manufacturer ensures long-term performance, minimal downtime, and consistent quality.

AccTek Group is a leading manufacturer of intelligent cutting equipment, offering advanced oscillating knife cutting solutions designed for both small-scale workshops and large-scale industrial production. With a focus on innovation, automation, and user-friendly operation, AccTek Group machines deliver high cutting accuracy, fast processing speeds, and seamless integration with modern design software.

Our systems are engineered for multi-material compatibility, featuring robust construction, modular tool options, and smart control systems. From foam and leather to corrugated board and composites, AccTek Group machines handle complex cuts with ease, without compromising on edge quality or throughput.

Backed by expert technical support, training, and global service, AccTek Group helps you get up and running quickly while maximizing ROI. If you’re looking for a dependable partner in digital cutting technology, explore AccTek Group’s full range of oscillating knife cutting machines and discover the smart choice for precision manufacturing.