Product Introduction

Types of 50W Fiber Laser Marking Machines

-

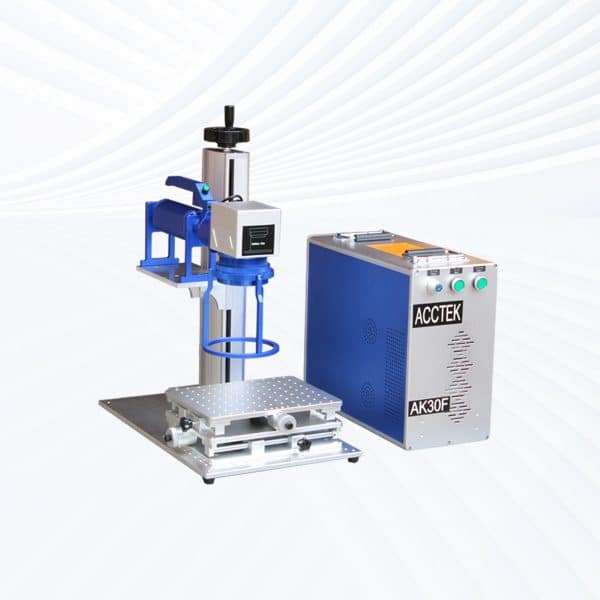

Desktop Fiber Laser Marking Machine

Rated 4.50 out of 5$2,000.00 – $20,200.00Price range: $2,000.00 through $20,200.00 This product has multiple variants. The options may be chosen on the product page -

Handheld Fiber Laser Marking Machine

Rated 5.00 out of 5$2,150.00 – $20,350.00Price range: $2,150.00 through $20,350.00 This product has multiple variants. The options may be chosen on the product page -

Split Fiber Laser Marking Machine

Rated 4.75 out of 5$2,000.00 – $20,200.00Price range: $2,000.00 through $20,200.00 This product has multiple variants. The options may be chosen on the product page -

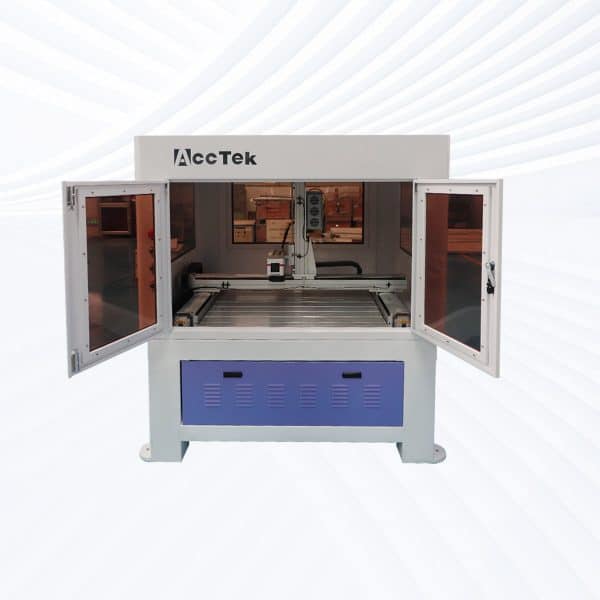

Enclosed Fiber Laser Marking Machine

Rated 5.00 out of 5$12,200.00 – $20,900.00Price range: $12,200.00 through $20,900.00 This product has multiple variants. The options may be chosen on the product page -

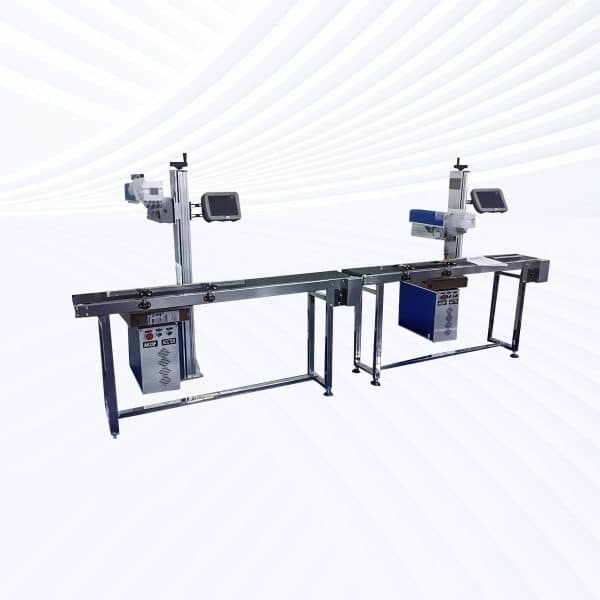

Flying Fiber Laser Marking Machine

Rated 4.75 out of 5$3,300.00 – $21,500.00Price range: $3,300.00 through $21,500.00 This product has multiple variants. The options may be chosen on the product page -

Screw Drive Fiber Laser Marking Machine

Rated 4.75 out of 5$7,700.00 – $27,000.00Price range: $7,700.00 through $27,000.00 This product has multiple variants. The options may be chosen on the product page -

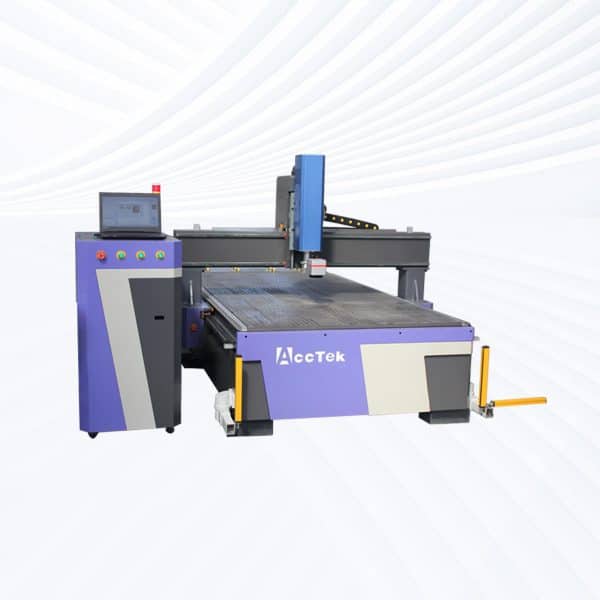

Rack Drive Fiber Laser Marking Machine

Rated 4.50 out of 5$7,800.00 – $26,800.00Price range: $7,800.00 through $26,800.00 This product has multiple variants. The options may be chosen on the product page

Laser Marking Capabilities

| Material | 20W | 30W | 50W | 60W | 70W | 100W |

|---|---|---|---|---|---|---|

| Stainless Steel (304/316) | Surface Mark; Black/Anneal | Surface Mark; Black/Anneal | Surface Mark; Black/Anneal; Shallow Engrave | Surface Mark; Black/Anneal; Shallow Engrave | Surface Mark; Black/Anneal; Shallow Engrave | Surface Mark; Black/Anneal; Shallow Engrave; deep relief |

| Carbon Steel (Mild) | Surface Mark | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave; deep relief |

| Tool Steel (HRC ≤55) | Surface Mark | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave; deep relief |

| Tool Steel (HRC 55–60) | Surface Mark | Surface Mark | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave (slow) |

| Titanium & Ti Alloys | Surface Mark; Black/Anneal (color) | Surface Mark; Black/Anneal | Surface Mark; Black/Anneal | Surface Mark; Black/Anneal | Surface Mark; Black/Anneal | Surface Mark; Black/Anneal |

| Nickel Alloys / Inconel | Surface Mark | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave; deep relief |

| Aluminum (Anodized) | fast Coating Removal (Surface Mark) | Coating Removal | Coating Removal | Coating Removal | Coating Removal | Coating Removal |

| Aluminum (Bare) | Surface Mark (MOPA Recommended) | Surface Mark; Shallow Engrave (MOPA Recommended) | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave; deep relief |

| Brass | Surface Mark | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave; deep relief |

| Copper | Surface Mark (MOPA Recommended) | Surface Mark; Shallow Engrave (MOPA Recommended) | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave | Surface Mark; Shallow Engrave; deep relief |

| Galvanized Steel | Surface Mark (Manage Zinc Fumes) | Surface Mark | Surface Mark | Surface Mark | Surface Mark | Surface Mark |

| Zinc-/Chrome-Plated Steel | Coating Ablation (Surface Mark) | Coating Ablation | Coating Ablation | Coating Ablation | Coating Ablation | Coating Ablation |

| Black Oxide/Phosphate Coat | Surface Mark; Black/Anneal | Surface Mark; Black/Anneal | Surface Mark; Black/Anneal | Surface Mark; Black/Anneal | Surface Mark; Black/Anneal | Surface Mark; Black/Anneal |

| Painted/Powder-Coated Metals | Coating Ablation (Surface Mark) | Coating Ablation | Coating Ablation | Coating Ablation | Coating Ablation | Coating Ablation |

| Hard Plastics (ABS/PC/PA)* | Surface Mark (MOPA; Laser-Markable Grades) | Surface Mark (MOPA; Laser-Markable Grades) | Surface Mark (MOPA; Laser-Markable Grades) | Surface Mark (MOPA; Laser-Markable Grades) | Surface Mark (MOPA; Laser-Markable Grades) | Surface Mark (MOPA; Laser-Markable Grades) |

| POM/PE/PP (Additive-Filled)* | Surface Mark (Additive-Filled; MOPA Recommended) | Surface Mark (Additive-Filled; MOPA Recommended) | Surface Mark (Additive-Filled) | Surface Mark (Additive-Filled) | Surface Mark (Additive-Filled) | Surface Mark (Additive-Filled) |

| CFRP/GFRP Composites | resin Surface Mark | resin Surface Mark | resin Surface Mark | resin Surface Mark | resin Surface Mark | resin Surface Mark |

| Ceramics (With Marking Paste) | Shallow Engrave (With Paste) | Shallow Engrave (With Paste) | Shallow Engrave; Surface Mark (With Paste) | Shallow Engrave; Surface Mark (With Paste) | Shallow Engrave; Surface Mark (With Paste) | Shallow Engrave; Surface Mark (With Paste) |

| Glass (With Marking Paste) | Shallow Engrave (With Paste) | Shallow Engrave (With Paste) | Shallow Engrave; Surface Mark (With Paste) | Shallow Engrave; Surface Mark (With Paste) | Shallow Engrave; Surface Mark (With Paste) | Shallow Engrave; Surface Mark (With Paste) |

| Wood/Leather (Organics) | Mot Recommended (use CO₂ laser) | Mot Recommended | Mot Recommended | Mot Recommended | Mot Recommended | Mot Recommended |

| PVC | Mot Recommended (toxic fumes) | Mot Recommended | Mot Recommended | Mot Recommended | Mot Recommended | Mot Recommended |

Compatible Materials

- Stainless Steel

- Carbon Steel

- Mild Steel

- Alloy Steel

- Aluminum

- Anodized Aluminum

- Brass

- Copper

- Bronze

- Titanium

- Tungsten

- Nickel

- Nickel Alloys

- Zinc

- Chrome

- Gold

- Silver

- Platinum

- Palladium

- Iron

- Magnesium

- Carbide

- Cobalt

- Inconel

- Lead

- Tin

- Galvanized Metals

- Powder-Coated Metals

- Painted Metals

- Stainless Steel with Mirror Finish

- Hard Plastics

- PEEK

- Nylon

- Polycarbonate

- Acrylic

- Epoxy Resin

- Ceramic

- Silicone

- Leather

- Some Stone Surfaces

Application of 50W Fiber Laser Marking Machines

Customer Testimonials

Comparison VS Other Marking Technologies

| Comparison Item | Fiber Laser Marking | Dot Peen Marking | Inkjet Printing | Chemical Etching |

|---|---|---|---|---|

| Marking Speed | Very fast; high throughput suitable for automation | Moderate; mechanical movement limits speed | Fast, but limited by drying time | Slow; multi-step chemical process |

| Marking Quality | Extremely precise, clean, and high contrast | Medium; mechanical impact causes rough marks | Good, but can smear or fade | Good, but depends on chemical consistency |

| Material Compatibility | Works on most metals, plastics, ceramics | Mainly metals | Works on metals, plastics, paper | Mostly metals and coated surfaces |

| Permanence | Permanent and wear-resistant | Permanent but can be affected by corrosion | Temporary; can fade over time | Permanent if surface is properly treated |

| Surface Damage | Non-contact; no physical damage | Causes indentation and vibration | None | Can affect surface coating or finish |

| Precision on Small Parts | Excellent for micro-marking | Limited precision | Moderate; depends on nozzle resolution | Good, but less controllable |

| Maintenance Requirements | Very low; no consumables | Regular pin and stylus replacement | Frequent ink and nozzle maintenance | Chemical disposal and tank cleaning needed |

| Operating Cost | Low after purchase; no consumables | Low to moderate; mechanical wear parts | High; ink and solvent costs | Moderate; chemicals and waste handling |

| Environmental Impact | Clean and eco-friendly | Minimal | Uses solvents and produces emissions | Generates chemical waste |

| Noise Level | Silent operation | Noisy (mechanical impact) | Quiet | Silent |

| Integration in Production Lines | Easily automated with software and robotics | Possible, but slower cycle time | Easy to integrate | Difficult; manual process |

| Marking Depth Control | Fully adjustable via software | Fixed by stylus pressure | Not applicable | Limited by etching duration |

| Suitable for 2D/QR Codes | Excellent; sharp, high-resolution marks | Poor readability | Limited durability | Not suitable for fine codes |

| Lifespan of Equipment | 100,000+ hours of laser life | Moderate; mechanical wear parts | Moderate; ink system replacements | Limited by corrosion of tanks and tools |

| Overall Marking Consistency | Excellent; repeatable, distortion-free | Inconsistent on uneven surfaces | Affected by ink flow and surface texture | Variable; depends on chemical balance |

Why Choose Us

High Precision

Our machines deliver sharp, detailed markings with excellent contrast, suitable for complex patterns and small components across metal, plastic, and other materials.

Fast Processing

Designed for speed and efficiency, our systems complete marking tasks quickly without compromising quality, making them ideal for high-volume production environments.

Low Maintenance

With durable components and minimal consumables, our machines offer stable long-term performance, reducing downtime and keeping operating costs low.

Flexible Solutions

We provide a variety of models and customization options to suit different materials, marking needs, and production setups, ensuring the right fit for your business.

Related Resources

How Accurate Is Laser Marking

This article explores how laser marking achieves superior precision, the factors that influence this precision, and how various industries ensure consistent, high-quality, and permanent markings.

How To Maintain Laser Marking Machines

This article provides a comprehensive guide to maintaining your laser marking machine, including cleaning, inspection, cooling system care, and troubleshooting to ensure consistent operation and durability.

How To Choose Laser Marking Machines

A comprehensive guide to selecting the right laser marking machine—covering materials, mark quality, laser types, software, integration, compliance, and total cost of ownership.

What Are The Common Defects In Laser Marking

This article explores common defects in laser marking, including causes, prevention strategies, and solutions to ensure high-quality, consistent results in various manufacturing applications.

Frequently Asked Questions

What Models Are Available For 50W Fiber Laser Marking Machines?

- Desktop Models: Designed for precision and efficiency, desktop systems offer stable, repeatable marking on metals, plastics, and coated materials. The higher 50W power enables faster processing and deeper engraving, ideal for industrial tags and hardware tools.

- Portable Models: Compact yet powerful, portable 50W fiber laser marking machines combine mobility with strong marking capability. They are excellent for small workshops or service operations that require frequent relocation without compromising performance.

- Handheld Models: Featuring ergonomic designs, handheld 50W lasers are ideal for marking large, fixed, or irregular surfaces such as machinery frames, pipes, or heavy molds. The increased power ensures deeper, clearer marks even on harder alloys.

- Fully Enclosed Systems: These enclosed machines integrate laser shielding, filtration, and safety sensors to meet industrial safety standards. Their 50W source offers rapid, high-contrast marking for electronics, medical devices, and precision tools.

- Flying Fiber Lasers: Engineered for automated production lines, flying 50W lasers can continuously mark products in motion—perfect for cables, packaging, circuit boards, and serialized production. The extra power ensures clarity at high conveyor speeds.

- Large-Area Screw-Drive Systems: Equipped with precision screw-driven motion control, these models deliver fine, vibration-free marking across large surfaces. The 50W laser ensures deep, durable engraving for molds, machine panels, and metal plates.

- Large-Area Open Rack-Drive Systems: Built for speed and accessibility, rack-drive designs handle oversized or batch-marking jobs efficiently. The open-frame layout supports quick loading and customization for industrial-scale production tasks.

How Much Do 50W Fiber Laser Marking Machines Cost?

- Desktop Models ($2500–2900): These compact, bench-top units are ideal for precision marking on metals, plastics, and coated parts. They deliver fast, stable performance with minimal maintenance, perfect for workshops and laboratories.

- Portable Models ($2500–2900): Designed for mobility and versatility, portable versions provide identical laser power to desktop models but with easier relocation. They’re suitable for multi-station marking tasks or small-batch customization work.

- Handheld Units ($2700–3100): Built for marking large, assembled, or irregularly shaped items, handheld 30W fiber lasers offer flexibility and power. They’re often used in machinery fabrication, automotive repair, and metal structure engraving.

- Fully Enclosed Systems ($3200–3600): Featuring sealed housings, observation windows, and fume extraction, enclosed machines enhance safety and cleanliness. They’re widely used in environments requiring laser protection and dust-free marking.

- Flying Fiber Lasers ($3800–4200): These continuous-marking systems integrate directly into conveyor or automated production lines. The 30W power supports high-speed, on-the-fly marking of serial numbers, barcodes, and logos.

- Large-Area Screw-Drive Systems ($7800–9400): Equipped with high-precision screw-driven motion control, these machines deliver excellent stability and fine detail across extended marking fields—ideal for mold, plate, or industrial component engraving.

- Large-Area Open Rack-Drive Systems ($7900–8400): Optimized for speed and accessibility, open rack-driven models handle oversized workpieces efficiently. The open layout simplifies part loading and supports customized fixtures for batch marking.

What Is The Marking Area Available For 50W Fiber Laser Marking Machines?

- 110×110 mm Field: This configuration provides the highest marking precision and energy density, ideal for applications requiring fine detail such as jewelry, electronic components, QR codes, barcodes, and small part identification. Because the laser’s focal spot remains highly concentrated, it delivers deeper engraving and better contrast on metal surfaces like stainless steel, aluminum, and brass.

- 200×200 mm Field: For larger workpieces, the 200×200 mm lens expands the marking coverage area while maintaining excellent accuracy. It is suitable for engraving logos, serial numbers, or data matrices on industrial parts, panels, tools, or mechanical housings. Though the energy per unit area is slightly lower due to the increased focal field, the 50W power output compensates effectively, ensuring consistent marking depth.

- Optional Customization: Depending on the optical setup, optional lenses can extend the marking field to 300×300 mm or 300×400 mm, though this may slightly reduce intensity and resolution. Such configurations are common in batch or palletized marking environments where multiple parts are processed simultaneously.

Is It Safe To Use 50W Fiber Laser Marking Machines?

- Laser Containment and Shielding: Fully enclosed or semi-enclosed fiber laser marking systems are the safest to operate. These models include protective housings and interlock systems that automatically shut down the laser when the cover is opened. Open-frame systems, such as desktop or handheld units, require additional precautions such as restricted-access work areas and physical barriers to contain stray reflections.

- Eye and Skin Protection: Because the 1064 nm fiber laser beam is invisible to the human eye, operators must wear laser safety glasses rated specifically for this wavelength and optical density. Direct or reflected exposure can cause permanent retinal injury. Additionally, skin should never be exposed to the laser beam or its reflections, as high-power pulses can cause burns.

- Fume and Particulate Control: When marking or engraving coated metals, plastics, or painted surfaces, the process can generate fumes or fine particulates. An exhaust or fume extraction system should always be used to maintain air quality and prevent respiratory irritation.

- Electrical and Thermal Safety: 50W fiber laser machines operate with high-voltage power supplies and generate localized heat in the marking zone. Proper grounding, ventilation, and cooling are necessary to avoid overheating or electrical hazards. Users should never service the laser source or optical path without professional guidance.

What Problems Might Arise When Using 50W Fiber Laser Marking Machines?

- Power Instability or Weak Marking: Inconsistent marking depth or faint engraving often indicates laser power fluctuations or fiber degradation. This can result from unstable electrical supply, improper software parameters (like frequency or speed), or aging optical fibers. Ensuring stable voltage, regular calibration, and clean optical components usually resolves this issue.

- Focus Misalignment and Distorted Marking: Over time, vibrations, movement, or frequent lens changes may cause focal length misalignment. This leads to blurry or uneven markings, especially near the edges of the marking field. Operators should check and recalibrate the focus distance periodically using a standard focusing gauge.

- Overheating or Fan Failure: Fiber laser components, including the laser source and control board, generate heat during extended operation. Inadequate cooling or blocked ventilation may trigger overheating alarms or cause shutdowns. Regularly clean dust filters, ensure air circulation, and avoid operating the machine in confined or hot environments.

- Optical Contamination: Dust, fumes, or metallic particles can settle on the lens or scanning mirrors, reducing beam transmission efficiency and causing marking inconsistency or surface burning. Routine lens cleaning with optical wipes and maintaining a dust-free environment prevents this problem.

- Software and Communication Errors: Sometimes, marking software malfunctions or communication errors between the control board and the computer lead to incomplete or misaligned markings. Updating drivers, using stable USB connections, and saving configuration backups help mitigate these issues.

- Material-Related Problems: Different materials react uniquely to fiber lasers. For instance, reflective metals like copper or aluminum may cause beam reflection, reducing efficiency or damaging optics. Adjusting marking parameters (pulse width, frequency, scanning speed) and using black oxide coatings can improve performance.

What Are The Environmental Requirements For 50W Fiber Laser Marking Machines?

- Temperature Requirements: The ideal ambient temperature for operating 50W fiber laser marking machines is 15℃ to 30℃ (59℉ to 86℉). Temperatures that are too high may cause electronic components or the laser module to overheat, triggering automatic shutdowns or reducing output power. Conversely, low temperatures can lead to fiber condensation or delayed startup. Consistent temperature control is especially important in production environments.

- Humidity Control: The relative humidity level should be kept between 40% and 70%, with no condensation. Excessive moisture can lead to short circuits, oxidation of connectors, and damage to optical components. In humid regions, it’s advisable to install dehumidifiers or air conditioners near the equipment to stabilize the environment.

- Air Quality and Cleanliness: Dust, smoke, and metal particles can contaminate lenses and mirrors, reducing marking quality. The work area should be clean, dry, and well-ventilated. An air filtration or exhaust system should be used when marking materials that release fumes or particulates, such as coated metals or plastics. This not only protects the optics but also ensures operator safety.

- Vibration and Stability: Fiber laser machines should be placed on a stable, vibration-free surface. Vibrations from nearby heavy machinery can cause beam distortion or positional errors during marking. Anti-vibration pads or isolated foundations can help reduce such mechanical interference.

- Power Supply and Grounding: Stable electrical input is essential. The recommended voltage is AC 220V ±10%, 50/60Hz, with proper grounding protection to prevent electrical noise or surges that might affect the control system or laser source. Avoid connecting the machine to the same circuit as high-power industrial equipment.

What Is The Service Life Of 50W Fiber Laser Marking Machines?

- Laser Source Lifespan: The core component of 50W fiber laser marking machines—the laser generator—typically offers a service life of 80,000 to 100,000 hours under normal working conditions. This translates to over 10 years of continuous operation in standard industrial use. Since fiber lasers use solid-state diodes and optical fibers with minimal moving parts, they require very little maintenance and exhibit superior stability compared to CO2 or diode-pumped lasers.

- Optical and Electronic Components: The lifespan of other components varies. The galvanometer scanner (responsible for beam positioning) generally lasts 30,000–50,000 hours, depending on usage intensity. Lenses and mirrors can last for several years if kept clean and free of dust or debris. Control boards and software interfaces are designed for long-term use, though periodic firmware updates and occasional replacements may be required.

- Environmental and Operational Factors: Service life can shorten if the laser operates in high-humidity, dusty, or poorly ventilated environments. Constant overheating or unstable voltage can also reduce the lifespan of the power supply or cooling fans. Maintaining stable temperature (15℃–30℃), proper grounding, and air filtration helps prevent premature wear.

- Maintenance and Usage Habits: Routine maintenance—such as lens cleaning, fan filter replacement, and parameter calibration—significantly extends operational life. Machines used continuously at maximum output may experience faster component degradation, while alternating moderate workloads can prolong performance stability.

How Should 50W Fiber Laser Marking Machines Be Maintained?

- Lens and Optical Path Maintenance: The scanning lens and protective window should be kept clean and dust-free at all times. Dust, oil, or smoke residue on optical components can reduce laser transmission efficiency, leading to weaker marks or surface burns. Use optical-grade wipes and isopropyl alcohol to gently clean lenses weekly, or more frequently if operating in dusty environments. Avoid touching optics with bare hands to prevent contamination.

- Cooling and Ventilation: Fiber laser marking systems typically use air cooling, but the internal fans and filters must remain unobstructed. Clean fan vents and replace air filters every 2–3 months to maintain proper airflow. Overheating from blocked ventilation can damage electronics or reduce laser stability. If the system includes an external chiller, ensure coolant levels and purity are checked regularly.

- Electrical and Power Stability: Ensure the laser is connected to a stable, grounded power source (AC 220V ±10%). Voltage fluctuations or electrical surges may cause system faults or shorten component life. Using an uninterruptible power supply (UPS) or voltage stabilizer helps protect the control board and laser driver.

- Software and Calibration: Regularly update marking software and firmware to maintain compatibility and prevent data loss or communication errors. Calibrate the focal distance and marking field alignment monthly, especially if the machine is relocated or used for different materials. Incorrect calibration can lead to distortions or uneven marking depth.

- Mechanical Components: Inspect the galvanometer scanner and working platform for looseness or vibration. Tighten bolts and lubricate moving parts as needed to prevent mechanical drift or positional errors during marking.

- Environmental Cleanliness: Operate the machine in a clean, temperature-controlled environment (15℃–30℃, humidity 40%–70%). Avoid exposure to excessive dust, oil mist, or vibration. Install a fume extractor when marking materials that release gases or particulates.