Product Introduction

Types of 12W UV Laser Marking Machines

-

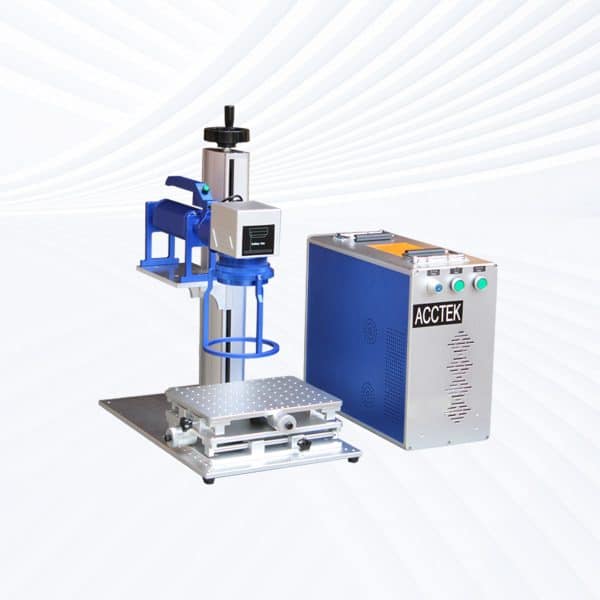

Desktop UV Laser Marking Machine

Rated 5.00 out of 5$3,900.00 – $9,300.00Price range: $3,900.00 through $9,300.00 This product has multiple variants. The options may be chosen on the product page -

Handheld UV Laser Marking Machine

Rated 4.75 out of 5$4,050.00 – $9,450.00Price range: $4,050.00 through $9,450.00 This product has multiple variants. The options may be chosen on the product page -

Split UV Laser Marking Machine

Rated 5.00 out of 5$3,900.00 – $9,300.00Price range: $3,900.00 through $9,300.00 This product has multiple variants. The options may be chosen on the product page -

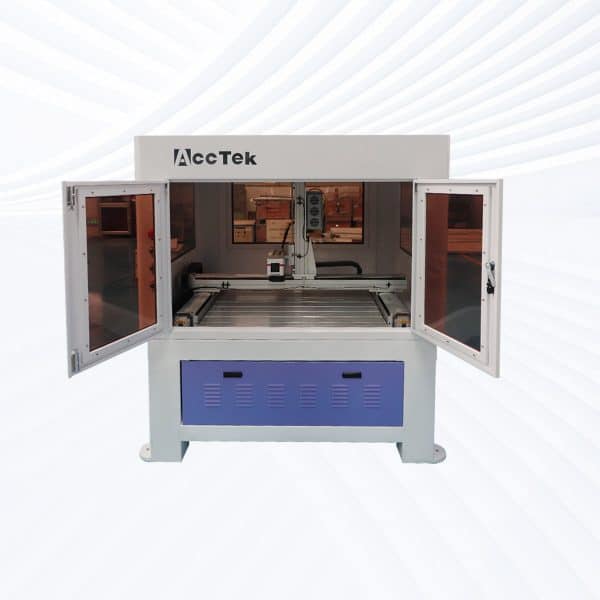

Enclosed UV Laser Marking Machine

Rated 4.75 out of 5$4,600.00 – $10,000.00Price range: $4,600.00 through $10,000.00 This product has multiple variants. The options may be chosen on the product page -

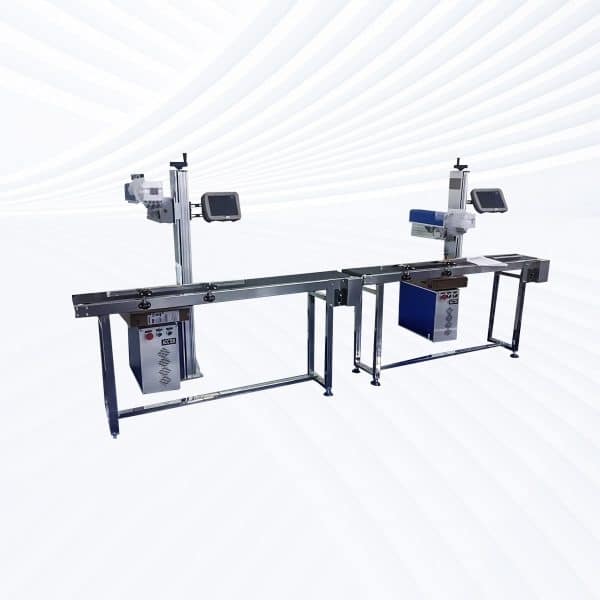

Flying UV Laser Marking Machine

Rated 4.75 out of 5$5,200.00 – $10,600.00Price range: $5,200.00 through $10,600.00 This product has multiple variants. The options may be chosen on the product page -

Screw Drive UV Laser Marking Machine

Rated 4.50 out of 5$9,600.00 – $16,100.00Price range: $9,600.00 through $16,100.00 This product has multiple variants. The options may be chosen on the product page -

Rack Drive UV Laser Marking Machine

Rated 4.50 out of 5$9,700.00 – $15,900.00Price range: $9,700.00 through $15,900.00 This product has multiple variants. The options may be chosen on the product page

Laser Marking Capabilities

| Material | 3W | 5W | 10W | 12W | 15W |

|---|---|---|---|---|---|

| ABS / Plastics (Non-Metallic) | Surface Mark; Color Change | Surface Mark; Deep Color Change | Deep Mark; Micro Engrave | Deep Mark; Micro Engrave | Deep Mark; Micro Engrave |

| PC / PA / PET / PBT / PP | Surface Mark; High Contrast | Surface Mark; Fine Engrave | Deep Mark; No Burn | Deep Mark; No Burn | Deep Mark; No Burn |

| Silicone / Rubber | Surface Mark; Shallow Engrave | Deep Engrave | Deep Engrave | Deep Engrave | Deep Engrave |

| Acrylic (PMMA) | Surface Mark; Smooth Edge | Surface Mark; Fine Engrave | Deep Engrave; Polished Mark | Deep Engrave; Polished Mark | Deep Engrave; Polished Mark |

| Glass (With or Without Paste) | Frosted Mark; Micro Text | Frosted Mark; Fine Line Engrave | Deep Frosted Engrave | Deep Frosted Engrave | Deep Frosted Engrave |

| Ceramics (Polished / Glazed) | Surface Mark; Micro Engrave | Surface Mark; Fine Engrave | Deep Engrave (High Precision) | Deep Engrave (High Precision) | Deep Engrave (High Precision) |

| Silicon Wafer / Semiconductor Substrate | Surface Mark (High Precision) | Surface Mark (High Precision) | Fine Engrave; Chip Marking | Fine Engrave; Chip Marking | Fine Engrave; Chip Marking |

| Anodized Aluminum | Coating Removal; High Contrast | Coating Removal; Fine Mark | Coating Removal | Coating Removal | Coating Removal |

| Painted / Coated Metals | Coating Ablation Only (No Metal Removal) | Coating Ablation | Coating Ablation | Coating Ablation | Coating Ablation |

| Stainless Steel (Thin Film Coated) | Film Ablation (No Metal Engrave) | Film Ablation | Surface Mark; Micro Text | Surface Mark; Micro Text | Surface Mark; Micro Text |

| PCB / FPC / Electronic Components | Surface Mark; QR Code | Surface Mark; QR Code; Fine Line | Fine Engrave; Trace Mark | Fine Engrave; Trace Mark | Fine Engrave; Trace Mark |

| Paper / Cardboard | Fine Marking; Non-Burn | Fine Marking; Non-Burn | Deep Mark; Micro Cut | Deep Mark; Micro Cut | Deep Mark; Micro Cut |

| Leather (Genuine / PU) | Surface Mark; Color Change | Surface Mark; Deep Mark | Deep Mark; Burn Mark | Deep Mark; Burn Mark | Deep Mark; Burn Mark |

| Film / PET Label / Transparent Foil | Surface Mark; High Contrast | Surface Mark; High Contrast | Surface Mark; Precise Mark | Surface Mark; Precise Mark | Surface Mark; Precise Mark |

| Epoxy / Resin / Plastic-Coated Boards | Surface Mark; High Precision | Surface Mark; Fine Engrave | Deep Engrave; Clean Edge | Deep Engrave; Clean Edge | Deep Engrave; Clean Edge |

| Glass Fiber / Epoxy Boards (FR-4) | Surface Mark; Fine Line | Deep Engrave | Deep Engrave | Deep Engrave | Deep Engrave |

| Wood / Paper / Bamboo | Surface Mark (Limited) | Surface Mark; Light Engrave | Surface Mark; Light Engrave | Surface Mark; Light Engrave | Surface Mark; Light Engrave |

| Foam / EVA | Surface Mark; Light Engrave | Surface Mark; Light Engrave | Deep Engrave; Cut (≤2 mm) | Deep Engrave; Cut (≤3 mm) | Deep Engrave; Cut (≤4 mm) |

| PVC | Not Recommended (toxic fumes) | Not Recommended | Not Recommended | Not Recommended | Not Recommended |

| Metals (Stainless, Carbon, Brass, Copper) | Not Recommended (use Fiber Laser) | Not Recommended | Not Recommended | Not Recommended | Not Recommended |

Compatible Materials

- ABS Plastic

- Polycarbonate

- Polyethylene

- Polypropylene

- Polyvinyl Chloride

- Acrylic

- Nylon

- PEEK

- PET

- Teflon

- Copper

- Titanium

- Gold

- Silver

- Acrylic Film

- Film Labels

- Transparent Plastics

- Cosmetics Packaging Materials

- Food Packaging

- Medical Plastic Components

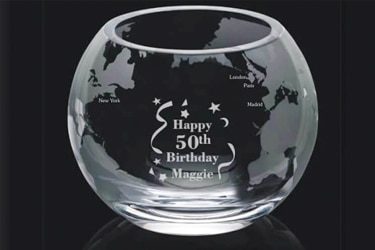

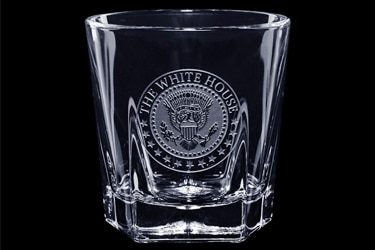

Application of 12W UV Laser Marking Machines

Customer Testimonials

Comparison VS Other Marking Technologies

| Comparison Item | UV Laser Marking | Dot Peen Marking | Inkjet Printing | Chemical Etching |

|---|---|---|---|---|

| Marking Principle | Cold laser process using ultraviolet light | Mechanical impact by stylus | Ink deposition through nozzles | Acid-based chemical reaction |

| Marking Speed | Fast; suitable for mass production | Moderate; depends on material hardness | Fast; high throughput | Slow; multi-step process |

| Marking Precision | Extremely high; suitable for micro-marking | Medium; limited by stylus size | Medium; depends on ink droplet control | High; but process can be inconsistent |

| Heat Effect on Material | Minimal (cold marking, no burning) | Generates frictional heat | None, but ink may smear | Can cause surface corrosion |

| Material Compatibility | Works on plastics, glass, ceramics, silicon, and coated metals | Mostly metals | Metals, plastics, paper | Metals and coated surfaces |

| Marking Quality | Smooth, clean, burr-free | Rough, dotted marks | Prone to fading or blurring | May leave uneven surface finish |

| Permanence | Permanent and wear-resistant | Permanent, but may deform material | Temporary; ink wears off | Permanent but prone to corrosion |

| Surface Damage | Non-contact, no surface damage | Indents surface | None | May etch or weaken material |

| Marking on Heat-Sensitive Materials | Excellent; no melting or deformation | Not suitable | Good | May damage material |

| Maintenance Requirements | Very low; no consumables | Frequent stylus replacement | High; regular ink and nozzle cleaning | Regular chemical disposal and replacement |

| Operating Cost | Low long-term cost; no consumables | Low to medium | High; continuous ink use | Medium; recurring chemical costs |

| Environmental Impact | Eco-friendly; no chemicals or waste | Minimal | Uses solvents and ink | Produces chemical waste and fumes |

| Automation Integration | Easy to integrate with automation and robotics | Moderate; mechanical limitations | Easy; digital control | Difficult; mostly manual process |

| Noise Level | Silent operation | Noisy due to impact | Quiet | Silent |

| Suitable Applications | Micro-marking, plastic, glass, electronics, medical devices | Metal parts, nameplates, industrial tools | Packaging, date codes, labels | Metal tags, industrial plates, decoration |

Why Choose Us

High Precision

Our machines deliver sharp, detailed markings with excellent contrast, suitable for complex patterns and small components across metal, plastic, and other materials.

Fast Processing

Designed for speed and efficiency, our systems complete marking tasks quickly without compromising quality, making them ideal for high-volume production environments.

Low Maintenance

With durable components and minimal consumables, our machines offer stable long-term performance, reducing downtime and keeping operating costs low.

Flexible Solutions

We provide a variety of models and customization options to suit different materials, marking needs, and production setups, ensuring the right fit for your business.

Related Resources

How Accurate Is Laser Marking

This article explores how laser marking achieves superior precision, the factors that influence this precision, and how various industries ensure consistent, high-quality, and permanent markings.

How To Maintain Laser Marking Machines

This article provides a comprehensive guide to maintaining your laser marking machine, including cleaning, inspection, cooling system care, and troubleshooting to ensure consistent operation and durability.

How To Choose Laser Marking Machines

A comprehensive guide to selecting the right laser marking machine—covering materials, mark quality, laser types, software, integration, compliance, and total cost of ownership.

What Are The Common Defects In Laser Marking

This article explores common defects in laser marking, including causes, prevention strategies, and solutions to ensure high-quality, consistent results in various manufacturing applications.

Frequently Asked Questions

What Models Are Available For 12W UV Laser Marking Machines?

- Desktop Models: Compact and rigid, desktop 12W UV laser marking systems provide exceptional stability and marking accuracy. They are perfect for plastics, glass, ceramics, and silicon wafers—commonly used in electronics, precision tools, and medical components.

- Portable Models: Offering the same precision in a movable design, portable 12W UV laser marking machines allow flexible operation across multiple stations. They are ideal for factories that require high power and flexibility for labeling parts or packaging on demand.

- Handheld Models: Built for large, irregular, or fixed objects, handheld 12W UV lasers enable direct marking without repositioning heavy workpieces. Their higher power output ensures deeper engraving and faster processing while maintaining non-thermal marking characteristics.

- Fully Enclosed Systems: Featuring sealed protective housings, observation windows, and integrated fume filtration, these systems ensure a safe, clean marking environment. They’re widely used in aerospace, electronics, and semiconductor industries where precision and safety are critical.

- Flying UV Lasers: Optimized for inline production, flying 12W UV lasers mark moving products such as cables, medical tubes, packaging films, and electronic components. Their high power supports fast throughput with consistent clarity even at high conveyor speeds.

- Large-Area Screw-Drive Systems: Equipped with precision ball-screw motion control, these machines provide excellent positional accuracy and smooth performance over wide marking areas. They are used for large-format applications like polymer films, glass panels, and industrial labels.

- Large-Area Open Rack-Drive Systems: With open-frame construction and high-speed rack-and-pinion motion, these models support rapid, multi-part processing for large or batch engraving tasks. Ideal for signage, multi-component assemblies, and industrial-scale marking.

How Much Do 12W UV Laser Marking Machines Cost?

- Desktop Models ($9300–9700): Compact and stable, desktop 12W UV laser marking systems offer outstanding beam quality for deep and high-speed marking. They’re ideal for fine engraving on plastics, glass, semiconductors, and ceramics—perfect for laboratories, precision electronics, and small-batch production.

- Portable Models ($9300–9700): Providing the same high power in a mobile format, portable UV lasers deliver flexibility for multi-station use while maintaining micron-level precision. They’re suited for factories or workshops where marking needs to shift between different production areas.

- Handheld Units ($9500–9900): Engineered for large, curved, or stationary parts, handheld 12W UV laser marking systems allow operators to perform direct marking without repositioning heavy materials. Their strong output ensures deep, sharp results on coated metals, plastics, and glass.

- Fully Enclosed Systems ($10000–10400): These models feature sealed laser housings, safety interlocks, and fume extraction for clean, safe operation. They’re widely used in aerospace, medical, and electronics manufacturing, where operator protection and surface purity are essential.

- Flying UV Lasers ($10600–11000): Built for continuous marking in automated production lines, flying 12W UV lasers mark moving products—like packaging, cables, or circuit boards—with exceptional speed and contrast. Their powerful beam supports high-throughput industrial environments.

- Large-Area Screw-Drive Systems ($14600–15000): Using precision ball-screw motion systems, these units achieve exceptional accuracy and uniformity across wide working areas. Ideal for industrial nameplates, polymer films, or precision panels where consistency across large surfaces is critical.

- Large-Area Open Rack-Drive Systems ($14700–15100): Equipped with rack-and-pinion motion and open architecture, these models combine speed and accessibility for oversized materials or multi-component engraving. They’re ideal for signage, display panels, or high-volume manufacturing.

What Is The Marking Speed Of 12W UV Laser Marking Machines?

- Material Type

- Plastics: UV lasers are commonly used for marking plastics like acrylic (PMMA), ABS, and polycarbonate. The marking speed for plastics typically ranges from 1,000 mm/s to 3,000 mm/s, depending on the type and thickness of the material. Softer plastics can be marked faster, while denser or thicker plastics may require slower speeds to ensure proper marking depth.

- Glass and Ceramics: Marking on glass or ceramics generally requires more precision, so the marking speed is slower, typically 100 mm/s to 500 mm/s. The machine moves more slowly to ensure detailed, high-quality engraving without damaging the surface.

- Design Complexity

- Simple Designs: Simple text, barcodes, or logos can be marked at higher speeds, up to 3,000 mm/s, as they require less processing time.

- Complex Designs: More intricate designs or images require slower speeds, generally 200 mm/s to 800 mm/s, to ensure high-quality, detailed marks. The laser may need to make several passes or adjust settings for detailed engraving.

- Typical Marking Speed

- The 12W UV laser marking machine typically operates at speeds ranging from 100 mm/s to 3,000 mm/s, depending on the material and design complexity. Softer, thinner materials are marked at faster speeds, while tougher, thicker materials require slower speeds to maintain the quality of the mark.

What Are The Disadvantages Of 12W UV Laser Marking Machines?

- Limited Marking Depth

- Shallow Marking: UV lasers, including the 12W version, are best suited for surface-level marking. While they are excellent for engraving fine details and performing high-contrast marks, their power is typically not sufficient for deep engraving. For deeper markings or cutting thicker materials, a higher-powered laser may be required. This can limit the machine’s applicability for industries that need to perform deeper cuts or engravings.

- Slower Marking Speed

- Lower Power and Speed: Despite the 12W power, UV lasers tend to be slower than higher-powered lasers like CO2 or fiber lasers. For example, marking on certain materials, especially thicker or more complex designs, can take more time. This slower marking speed can lead to reduced efficiency in high-volume production environments where speed is critical. For simpler designs or high-speed marking, the machine’s speed can be competitive, but it may fall short for large-scale production runs.

- Material Limitations

- Material Compatibility: While 12W UV lasers are effective on a wide range of materials, their performance on certain metals is limited. These lasers typically struggle with bare metals (such as stainless steel or aluminum) unless coated. The laser’s effectiveness is greatly diminished on reflective surfaces, making it less suitable for some types of metal marking compared to fiber lasers, which are more suited for metals.

- Effectiveness on Harder Materials: UV lasers may also be less effective on harder materials like thick ceramics or glass compared to other laser types like CO2 lasers. While they can engrave glass and ceramics, they are generally slower and less effective for cutting.

- Higher Operating Costs

- Maintenance and Consumables: UV laser systems generally have higher operating and maintenance costs compared to CO2 lasers. The cooling system in UV lasers, which is essential to prevent overheating, may require more frequent maintenance. Additionally, optical components like lenses and mirrors can degrade over time due to exposure to high-intensity UV light, leading to higher replacement costs.

- Safety Concerns

- UV Light Hazard: As with all UV lasers, there is a significant safety risk associated with UV radiation. Operators must wear specialized protective goggles to prevent eye damage, and strict safety protocols must be followed. Even with protective equipment, the risk of accidental exposure remains higher compared to lasers like CO2, which are less hazardous in terms of UV radiation.

What Is The Service Life Of 12W UV Laser Marking Machines?

- Laser Source: The laser diode in a 12W UV laser is one of the key components influencing its service life. The diode is designed to last 20,000 to 30,000 hours under normal operating conditions. However, if the machine is frequently operated at full power or in conditions that cause it to overheat, its lifespan may be reduced. Proper usage and power adjustments help maintain optimal performance and prolong the diode’s life.

- Cooling System: The cooling system is crucial in preventing overheating, especially in UV laser marking systems, where heat management is critical. Machines typically use either air cooling or water cooling, and maintaining the cooling system can extend the service life of the laser. For water-cooled systems, coolant levels should be regularly checked and replaced as needed. Proper airflow should be maintained in air-cooled systems to prevent overheating, which can damage the laser components.

- Optical Components (Lenses and Mirrors): Lenses and mirrors used to focus and direct the UV laser beam can wear out over time due to exposure to the high-intensity light. Regular cleaning of these optical components is essential to prevent dirt or debris buildup, which can affect marking quality. Damaged or worn-out optics should be replaced to ensure the laser operates efficiently. These components may need to be replaced every 1 to 2 years, depending on usage.

- Material Type and Usage: The materials marked also affect the lifespan of the machine. Marking harder materials, such as metals or thicker plastics, can place more strain on the laser components. UV lasers are particularly suited for marking plastics, ceramics, and glass, but if operated continuously on harder materials, the system may experience faster wear.

- Maintenance and Environmental Factors: Regular maintenance is key to extending the lifespan of the machine. This includes cleaning optical components, checking the cooling system, and ensuring proper calibration. The environmental conditions, such as temperature and humidity, also play a role; the machine should be operated in a clean, dry, and temperature-controlled environment to avoid damage to sensitive parts.

What Training Is Required To Operate 12W UV Laser Marking Machines?

- Laser Safety Training

- Understanding Laser Classifications: The 12W UV laser is typically classified as a Class 4 laser, meaning it can cause serious eye injury or skin burns if proper precautions aren’t taken. Operators must be trained in the hazards associated with UV lasers and learn to recognize the potential risks of direct or scattered laser radiation.

- Protective Equipment: Operators should be trained to properly use laser safety goggles specifically designed for UV wavelengths (typically 355 nm) to protect their eyes. Additionally, training should cover the proper use of face shields, long-sleeve protective clothing, and fire-resistant gloves, as these may be needed in certain conditions.

- Machine Setup and Operation

- Component Familiarization: Operators should understand the key components of the machine, such as the laser source, cooling system, optics (lenses and mirrors), and the control panel. Proper setup is essential to ensure safe and efficient operation, including calibration of the machine for accurate marking.

- Material Handling: Operators need to know how to load materials correctly onto the marking platform to avoid misalignment. Training should also cover how to properly handle materials, including plastics, metals, and ceramics, as UV lasers are most commonly used for these.

- Software Operation: The machine is typically controlled through laser marking software, which allows the operator to adjust parameters such as power, speed, and frequency. Operators should be trained to create, edit, and upload designs and to adjust machine settings for different materials and marking types.

- Maintenance and Troubleshooting

- Routine Maintenance: Operators should learn how to perform basic maintenance tasks, such as cleaning the optical components (lenses, mirrors), checking the cooling system, and ensuring that the machine is free of debris. Proper maintenance ensures the machine remains in optimal condition and reduces the risk of breakdowns.

- Troubleshooting: In case of operational issues, operators should be trained to identify common problems, such as misalignment, laser power loss, or optical component degradation, and know how to address them efficiently.

- Material Compatibility

- Material-Specific Guidelines: Different materials require different settings for optimal results. Operators should be trained to understand how to adjust the power and speed settings based on the material being marked. For example, plastics may require lower power compared to metals to avoid damage.

- Safety Procedures

- Emergency Protocols: Operators must know what to do in case of a fire, electrical malfunction, or laser misfire. This includes having access to fire extinguishers and understanding evacuation protocols.

- Environmental Safety: Since UV lasers can produce harmful fumes when marking certain materials, operators should also be trained on using fume extraction systems to prevent inhalation of hazardous fumes.

What PPE Is Required When Operating 12W UV Laser Marking Machines?

- Laser Safety Glasses

- Purpose: The most crucial piece of PPE when using a UV laser is laser safety glasses. These glasses are specifically designed to protect the eyes from harmful UV radiation, particularly at 355 nm, which is the typical wavelength of UV lasers.

- UV Protection: The glasses should be rated for UV protection, as ordinary sunglasses or safety glasses won’t provide adequate shielding against UV rays. They must block both direct and reflected UV light, which could cause permanent eye damage if exposed.

- Face Shield or Goggles

- Face Shield: In addition to safety glasses, a face shield is recommended for extra protection, especially if the operator is working with reflective materials or intricate marking jobs that may scatter laser light. The face shield provides additional coverage to the face and eyes.

- Safety Goggles: If face shields are not used, goggles that offer full protection against UV light are necessary to shield against reflected or scattered beams.

- Protective Clothing

- Flame-Resistant Clothing: The operator should wear flame-resistant or fire-retardant clothing, as some materials can catch fire when exposed to the high heat generated by the laser. Cotton or similar natural fabrics are recommended because they provide a physical barrier and are less likely to catch fire.

- Long-Sleeve Shirt and Pants: Long sleeves and pants should be worn to minimize skin exposure to potential laser radiation or heat. Synthetic fabrics that could melt should be avoided.

- Hearing Protection

- Ear Protection: Although UV lasers themselves are relatively quiet, the laser system may be operating alongside other equipment, such as air compressors or extraction systems. In a noisy environment, hearing protection such as earplugs or earmuffs may be necessary to reduce the risk of hearing damage.

- Respiratory Protection

- Fume Extraction: Marking materials, especially plastics and metals, can release harmful fumes when exposed to the laser. The machine should be equipped with a fume extraction system to capture these fumes and prevent inhalation.

- Respirators: In some cases, especially if the fume extraction system is not adequate, operators may need to wear respirators to protect against inhaling toxic fumes, vapors, or particles.

- Work Area Setup

- Ventilation: The area where the machine operates should be well-ventilated to ensure any fumes generated are effectively removed. Proper airflow also prevents overheating of the machine.

How Should 12W UV Laser Marking Machines Be Maintained?

- Laser Source Care

- The laser source (often a diode or fiber laser) is the heart of the UV laser marking machine. It typically lasts between 20,000 to 30,000 hours under proper conditions, but its lifespan can be shortened by frequent overuse or operating at maximum power.

- Power Calibration: Regularly check and calibrate the laser’s power to ensure it is operating at optimal levels. A decrease in power could indicate that the diode is wearing out or that the settings need adjustment.

- Cooling System Maintenance

- Cooling System Functionality: Whether the system is air-cooled or water-cooled, maintaining a proper cooling system is essential to prevent overheating, which can damage the laser components.

- For water-cooled systems, check coolant levels regularly, clean the cooling pipes, and replace the coolant as needed to ensure efficient heat dissipation. For air-cooled systems, ensure proper airflow by regularly cleaning the fans and filters.

- Overheating Prevention: Always monitor the machine’s temperature to avoid thermal stress on the laser and other components.

- Optical Components (Lenses and Mirrors)

- Cleaning: Over time, lenses and mirrors can accumulate dust, debris, or material residue, which may affect the laser’s performance. Clean these optical components regularly with a soft, lint-free cloth and optical lens cleaner.

- Inspection: Inspect lenses and mirrors for signs of wear, scratches, or discoloration. Damaged components can distort the laser beam, leading to poor marking quality. Replace any damaged optical components as necessary.

- Air Assist and Fume Extraction

- The air assist system ensures the removal of debris and cooling of the material being marked. Check and clean the nozzles regularly to prevent blockages and ensure proper airflow.

- Fume Extraction: The marking process can generate harmful fumes, especially when working with plastics or metals. Ensure the fume extraction system is working efficiently by regularly cleaning filters and checking the fan operation. This helps avoid exposure to harmful vapors and maintains air quality in the workspace.

- Software and Firmware Updates

- Software Maintenance: Keep the control software up to date to ensure the machine operates efficiently and benefits from any new features or improvements. Manufacturers often release updates that optimize performance or fix bugs, so be sure to periodically check for new software versions.

- Calibration and Settings: Ensure that the machine’s settings are calibrated according to the material being processed. Misalignment or incorrect settings can lead to inconsistent results.

- General Machine Maintenance

- Workspace Cleanliness: Regularly clean the machine’s surface to prevent dust or material buildup, which could interfere with its operation. Keeping the workspace clean also prevents external contamination of the laser system.

- Wiring and Electrical Checks: Inspect the wiring and electrical connections for any signs of wear or fraying. Ensure all cables are securely connected to prevent electrical faults.