Engraving machines are used to cut and engrave some materials, making them products used in people's daily life, including some wood boards, MDF, leather, PVC, acrylic, etc., which are applied to all walks of life, so we usually see The billboards, industrial products, furniture, etc. that have been visited all have engraved fuselage shadows. Of course, during the use of the

engraving machine, the programming of the engraving machine will definitely be involved. Then let us talk about the programming methods and characteristics of the engraving machine?

What are the programming methods of the engraving machine?

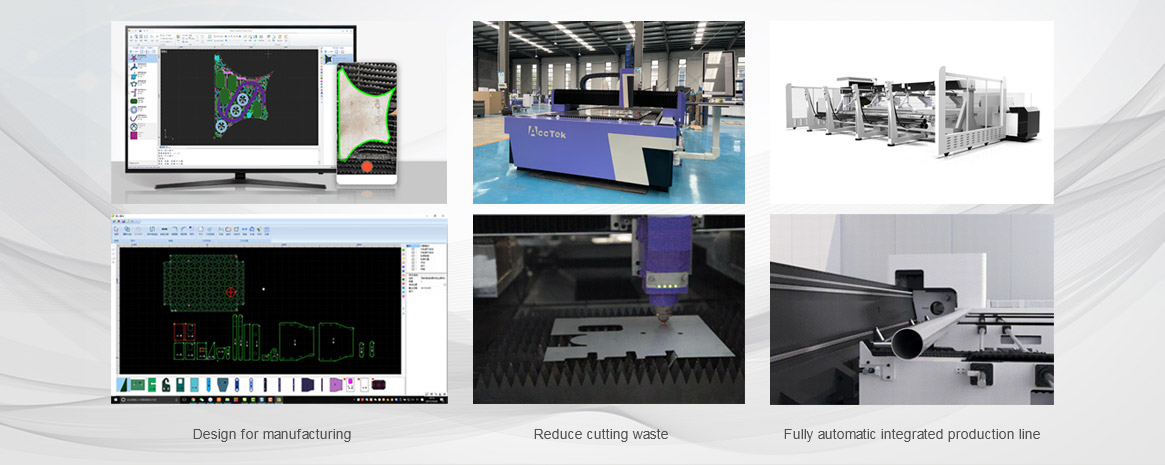

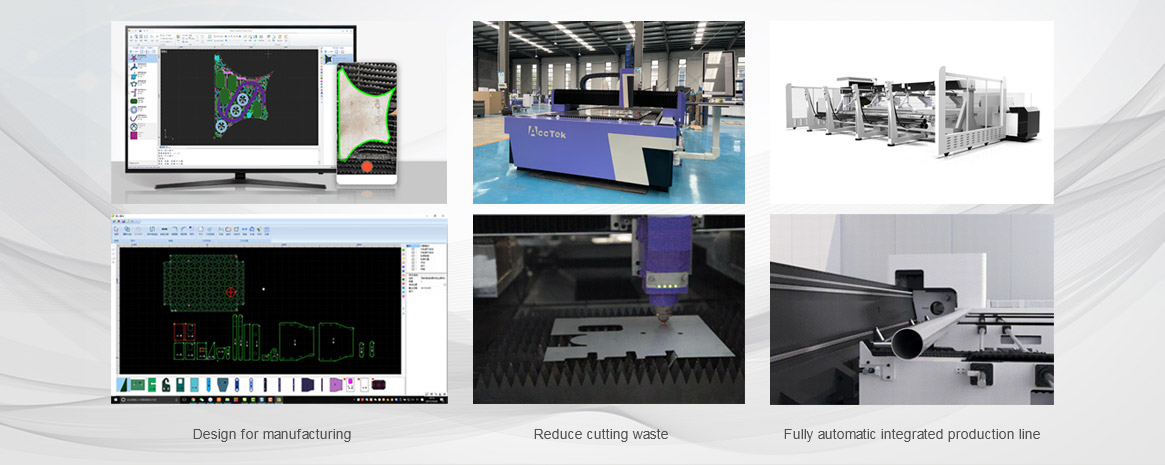

Programming is divided into manual programming and automatic programming. Manual programming is the process of manually programming parts. Automatic programming refers to the method of using the automatic programming system composed of the computer and its peripheral equipment to complete the programming work. It is also called the computer-assisted programming.

1. Manual programming: Regarding the parts with less complex geometric shapes, the programming workload is small, the processing procedures are not many, the chance of slipping is small, it is fast, light, and does not require special prerequisites, especially in the programming of CNC lathes. , Manual programming is still commonly used in the contour processing composed of points, straight lines, and arcs, and manual programming is the main content of CNC lathe processing programming. Even in the future of rapid growth of automatic programming, the main position of manual programming is not a substitute, and it is still the foundation of automatic programming.

2. Automatic programming: Regarding complex parts, such as the processing appearance of some non-circular curves and curved surfaces, perhaps the geometric shape of the parts is actually not complicated, but the workload of the programming is very large, and it may be parts that require complicated processes and procedures. Because the numerical calculation in the processing and programming process is extremely cumbersome and the programming workload is large. If manual programming is used, it is often time-consuming and inefficient, and the miss rate is high, or even impossible to complete. Therefore, automatic programming must be used in such situations. Methods. Compared with manual programming, this method has the advantages of reducing programming labor intensity, shortening programming time and improving programming quality.

However, the cost of hardware and software setup equipment for automatic programming is relatively high, and it is used more in machining centers and CNC milling machines, and less used in CNC lathes.

In the actual operation steps, the software of the

engraving machine is bundled with the machine tool. When the software presets the parameters of the machine tool, after importing the data model, we only need simple operations to move the product data model to the predetermined position.

Taking into account that the workpiece may be deformed during the cutting process, we must cut in a certain order, first hole, then contour, first inside and then outside, and select the processing steps in sequence. As long as we choose to finish, the software will automatically calculate the program. .

In principle, the software will automatically complete without cutting, collision, and overtravel, but sometimes manual modification is required. However, the software is still relatively intelligent and easy to operate. It only takes a few simple steps to complete the program modification. .