Laser rust removal machine is widely used in the industrial field, but for users who want to buy for the first time, they should first understand its performance and effect.

In daily life or industrial production, people often encounter the situation that metal products rust. In particular, metal workpieces used in outdoor environments will rust after being wetted by rain for many times. There are many traditional metal rust removal methods, such as cleaning with chemicals, or grinding to remove rust. However, these two methods have the disadvantages of polluting the environment or damaging the metal substrate. So which rust removal method can avoid these problems?

With the development of science and technology, a new rust removal method has become popular in the industrial field, which is to use a laser rust removal machine to remove rust on the metal surface. Is it good or bad to remove rust with laser? In fact, using laser to remove rust can not only remove rust, but also remove some other dirty substances. For example, this laser cleaning machine can remove the paint on the metal surface or remove the oil stain on the metal surface and so on. Let me introduce to you the characteristics and effects of using laser rust removal, so that you can better understand its function.

Laser rust removal has low operating costs and is more environmentally friendly

Laser rust remover is really good for removing rust left on metal surfaces. In the process of removing rust, the laser cleaning machine does not require any other consumables and media except the need to power on to generate a laser. Therefore, there is no need to spend money on consumables such as chemicals or dry ice for a long time, and there is no need to consider the storage and transportation of media. Therefore, the use of laser to remove rust is really very low operating cost, as long as the power is turned on, and then normal work can be started. Using laser cleaning machine is a very environmentally friendly rust removal method, and there is no need to worry about the discharge of waste during the rust removal process, and it is not harmful to the health of the staff.

Laser rust removal will not cause damage to metal substrates

Laser rust remover is a kind of high-tech equipment that irradiates the metal surface by emitting a high-energy laser beam to peel off the contaminants on the surface of the material. Since this kind of equipment removes rust in a non-contact way in actual use, and there is no thermal effect in the process of laser to removal rust, the absence of thermal effect means that there will be no damage to the metal workpiece. Of course, because the laser rust removal method is non-contact, it will not cause mechanical damage, so it can well protect the metal surface during the process of removing rust.

The laser cleaning machine is easy to operate and easy to move

Using a laser cleaning machine to remove rust is very simple and easy to operate. The handheld laser rust removal gun is ergonomically designed, and the handle is easy to grasp. The operator only needs to hold the handle of the laser cleaning machine to align the surface to be cleaned of rust, and then start laser to removal rust. And the laser cleaning machine is also very suitable for large-scale rust removal operations. For example, if there is rust on the steel plate of building materials, a laser cleaning machine can be used to remove the rust.

Now the machines produced by laser cleaning machine manufacturers are relatively small in size, and a universal wheel is installed at the bottom of the machine main body. Users can easily bring the laser rust remover to the workplace where metal rust needs to be removed for work. The operator only needs to hold the laser rust removal gun to aim at the steel surface, and then move back and forth to remove the rust very efficiently.

What is the effect of laser rust removal?

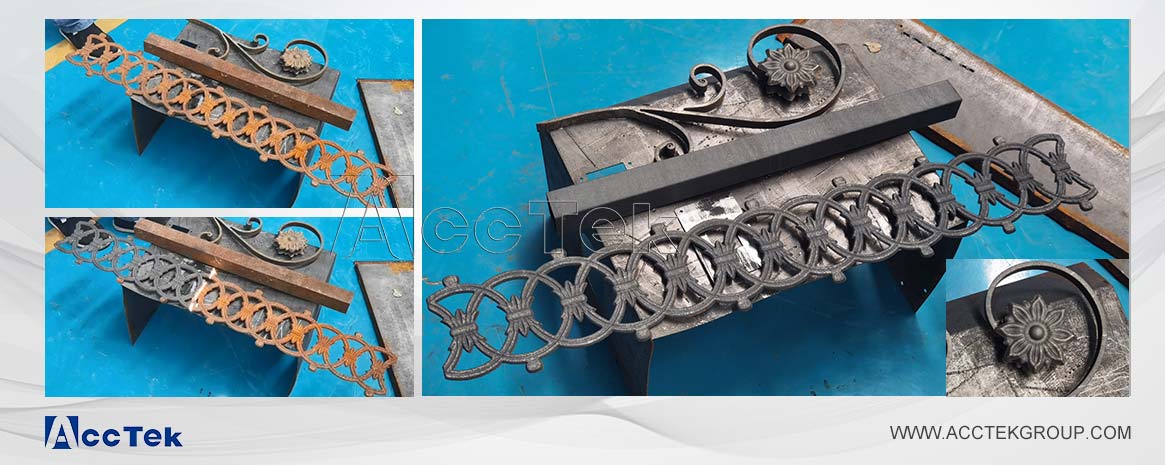

Laser rust remover has so many advantages, how about its actual rust removal effect? Here is a set of comparison charts before and after using laser to removal rust. This is a rust removal sample sent to us by a user who is planning to buy a laser cleaning machine. He uses machines mainly to remove rust from metal products such as iron gates and iron fences. So our engineer sent him a video of cleaning the rusted iron fence. You can get it online if you need to see the full video.

In addition to removing rust, the laser cleaning machine can also laser to remove paint, laser to remove oil, and laser to remove graffiti. The images below show you the effect of laser cleaning these contaminants. It can be seen that laser cleaning can achieve unparalleled results.

Another very convenient feature of the laser cleaning machine is that it saves a variety of rust removal modes in its operating system. Users can choose different laser cleaning modes according to their needs to remove rust on the surface of rust objects. Each of these modes will correspond to corresponding parameters, and these parameters can be adjusted by the user. Therefore, the laser rust removal machine is a kind of metal descaling equipment that is very flexible to use and can be adapted to various application scenarios.

Through the above introduction to the laser rust removal machine and its effect display, I believe you have a comprehensive understanding of laser rust removal. If you want to learn more about laser cleaning machines or watch the laser rust removal video. You can click on

Laser Cleaning Machine for details.