The cutting head of the

laser cutting machine is a very important core accessory in the whole machine. The quality of the cutting head will directly affect the quality of the processed products and the working efficiency of the use. Therefore, when we choose the laser cutting head, we must pay attention to the choice of good quality and reputation. Brand cutting head, the price of the cutting head is relatively expensive compared to other accessories, so the maintenance of the laser head is more important in the use of ordinary work.

Because good maintenance not only greatly increases the service life of the laser cutting head, but also ensures the smooth processing of the production process, and can effectively ensure the accuracy of the workpiece and save the use of cutting gas and electricity. So how should we do the maintenance of the laser cutting head? This should be divided into two parts: daily maintenance and regular maintenance.

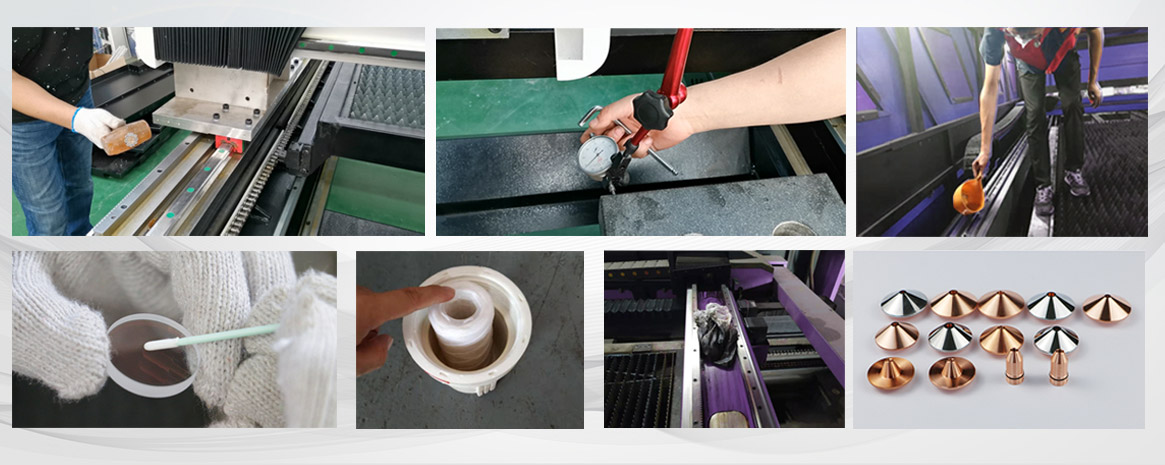

Daily maintenance

1. Check whether the position of the cutting head is accurate every time before starting the machine to ensure the accuracy of the starting point, height and other data of the

laser cutting head, and avoid collisions and other accidents during the work process.

2. Check whether the amount of cutting gas is sufficient. If air is used, check whether the pressure of the air pump is sufficient.

3. Check whether the water volume and water temperature of the cooler meet the set requirements of the equipment, and the water volume should be sufficient during work to avoid damage to the laser cutting head due to insufficient cooling water.

4. Check the oil circuit, gas circuit, water circuit, pipelines and joints of pneumatic components for leaks, and whether the parts are in good condition.

Regular maintenance

We should make a weekly inspection plan when we use it, or customize the inspection plan according to the actual frequency of the machine.

1. Regularly check the loss of the cutting nozzle of the cutting head. If the loss is serious, replace it in time

2. Check the sharpness of the lens at each part of the cutting head and clean it reasonably

3. Check the cleanliness and unobstructed conditions of all pipes and joints-to ensure that there are no impurities and no blockages

4. Check whether the fixed parts of the cutting head are loose

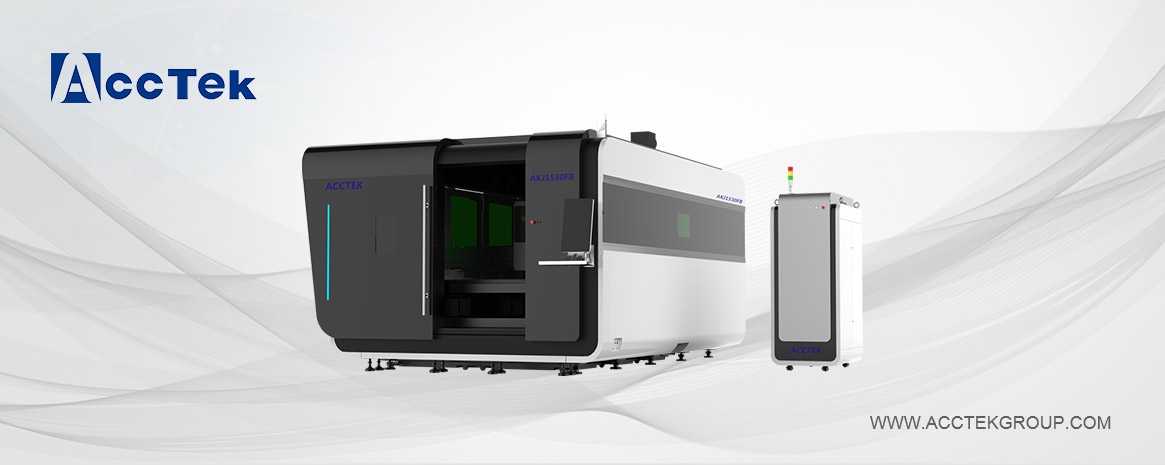

The

heavy-duty fiber laser cutting machine produced by our company uses Raytool cutting head.It is a Swiss brand, it is an autofocus cutting head, suitable for medium and high power fiber lasers in industrial applications. Using imported closed-loop motor, it can perforate and cut various material thicknesses at high speed.

If you encounter some problems when purchasing a fiber laser cutting machine, you can communicate with us online at any time, and our staff will provide you with a suitable solution according to your actual cutting needs.