Automatic tool changer cnc router is the highest technology engraving machine equipment, it has an independent tool library, can automatically change the required tools in the workpiece processing, do not need to stop work.To be able to carve complex patterns, choose different cutting tools, greatly accelerate the work efficiency, improve product quality.Automatic tool changing engraving machine is also the ultimate trend of the development of CNC engraving machine equipment.

Characteristics

1. Dulian-style/straight-line knife storehouse is a standard machining center with high cost performance.

2. The machine is suitable for the processing of diversified compound products and has a wide range of functions: drilling, cutting, trimming, etc.

3, the table is a strip vacuum adsorption table, which can not only strongly absorb materials of different areas, but also use fixtures to fix various shaped materials, which is flexible and convenient.

4. Row drilling is optional.

Basic Features

Italy HSD spindle

Italy HSD spindle is suitable for engraving machinery and equipment, CNC numerical control equipment, wood processing, metal processing, plastics, glass and other industries, and used in milling, drilling and milling, cutting and other fields, both production and assembly, high speed motors, high-speed motor, high frequency motor in any link for the choice of raw materials and components are demanding, can't allow any defects.

The spindle of Italian HSD is equipped with two high-precision angular contact bearings to support radial load, and optional collet fittings. The new generation of unique eight-tool library tool changing system is adopted. The tool changing time is 15 seconds, avoiding the tedious manual tool changing and realizing the multi-purpose of one machine.The Italian HSD spindle can also adjust the position of the blade tip, allowing the dynamic adjustment of the processing speed and the cutting speed during the processing, and controlling the automatic completion of multi-layer 3D processing.Intelligent 3D computer numerical control function, truly realize three axis linkage, can be fast, smooth THREE-DIMENSIONAL engraving or cutting.

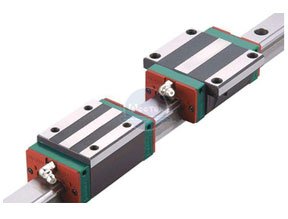

HIWIN Guide rails

1. High positioning accuracy

When linear guide is used as linear guide, the friction mode of linear guide is rolling friction, not only the friction coefficient reduces to 1/50 of sliding guide, but also the difference between dynamic friction and static friction force becomes very small.Therefore, when the bed is running, there will be no sliding phenomenon, can achieve m level positioning accuracy.

2. Low abrasion can maintain accuracy for a long time

The traditional sliding guidance will inevitably cause the poor movement precision of the platform due to the greasy countercurrent effect, and the insufficient lubrication during the movement will lead to the wear of the contact surface of the running track, which will seriously affect the accuracy.The abrasion of the rolling guide is very small, so the machine can maintain the accuracy for a long time.

3. It is suitable for high-speed movement and greatly reduces the driving horsepower required by the machine

Because the linear guide rail movement friction is very small, only a small power can allow the bed to run, especially in the bed in the working mode of regular round-trip operation, can significantly reduce the power loss of the machine.And because the heat produced by its friction is small, it is suitable for high speed operation.

4. It can bear the load of upper, lower, left and right directions at the same time

Because of the special beam structure design of linear guide, it can bear the load of the upper, lower and the left direction at the same time, unlike the lateral load that sliding guide can bear in the direction of parallel contact surface, it is easy to cause the poor operation accuracy of the machine.

5. Easy to assemble and interchangeable

During assembly, as long as the assembly surface of the guide rail on the milling or grinding bed is cut, and the guide rail and slider are respectively fixed on the machine with specific torque in accordance with the suggested steps, the high precision of processing can be reproduced.The traditional sliding guidance has to shovel the running track, which is time-consuming and time-consuming.The linear guide rail has interchangeability, and the slider or guide rail or even linear guide group can be replaced respectively, so that the machine can regain high precision guidance.

JAPANESE YASKAWA servo motor

1. Excellent performance

Its performance ranks first in the industry.The amplifier has the highest response in the industry, which greatly reduces the setting time and enhances the vibration suppression function. By adding and improving the vibration suppression function, the following performance can be improved and the setting time can be shortened.In addition, it can reduce the vibration of the front end of the machine when driving and stopping.The mechanical properties are improved by combining the inertia motor.

2. Easy to start

Simple installation setting, simple tuning.

Vacuum adsorption table

Vacuum adsorption table directly put the plate on the engraving machine surface, can be automatically fixed.Relatively time - saving, fixed more firmly.But also not suitable for all processing technology use, choose what type of woodworking engraving machine, or according to the customer processing technology to choose.

Vacuum adsorption table woodworking engraving machine equipment price is higher, its structure by the vacuum pump and high quality electric wood composition, can be divided into six and eight zones of vacuum adsorption, so as to enhance the adsorption function;The power of vacuum pump is 5.5 kW.When we process the plate, open the vacuum valve, engraving plate will be fixed directly, than manual fixing to save a lot of time, and fixed more stable, suitable for wood door processing, large plate relief sculpture.

Machine maintenance

1,The most important thing is to maintain a clean working environment, which can not only reduce the probability of failure, but also provide a relaxed mood.

2,Be careful of electric shock. The interface of the woodworking engraving machine should not be touched casually.Do not work in dark, damp places. Do not work in flammable liquids and gases.

3,Keep outsiders and children away from the workplace. Visitors not related to homework should be kept at a suitable distance.When machining, the operator's hand should be away from the machining spindle;When processing stops, cut off the power supply, prohibit outsiders, children touch at will.

4,According to the reasonable working process allowed by the system, do not use the low-power spindle to do heavy work, do not use indiscriminate processing tools, before processing must be done to fix the material, do not use hands to fix.

5,When working, do not wear loose clothes and jewelry, so as not to be involved in the woodworking carving machine, it is recommended to wear non-slip rubber shoes, long hair to wear a hat, when processing metal or debris materials, must wear goggles to protect the eyes

6,Do not pull out the connecting cable or the power plug, the cable should be away from heat sources and inflammable and explosive items, while avoiding contact with sharp objects, refer to the maintenance procedures of the manual, timely lubrication, regular inspection and maintenance, to ensure the reliable use of the entire woodworking engraving machine performance.

7,When changing the tool, cut off the power supply of the spindle motor; when changing the processing material, cut off the power supply of the numerical control equipment; before starting the machine, remove the wrench of the machining spindle; keep a sufficient distance in the processing process, keep your head clear; do not operate when tired.

8,If do not use the

engraving machine for a long period of time, regular weekly refueling idling, to ensure the flexibility of the transmission system, require engraving machine under 10 hours/day continuous operation, ensure the normal work of the cooling water clean and the water pump, water shortage phenomenon to appear water-cooled spindle motor, regular replacement of cooling water, in order to prevent the water temperature is too high, circulating water as much as possible, can change the large capacity water tank.