Overview of CNC Machine Tools

CNC machine tools are mechanical and electrical equipment that can be processed automatically by using a programmed processing program.Very many different kinds of CNC machine tools, including the CNC lathe, CNC grinding machine, CNC boring machine, CNC planer, CNC milling machine, CNC vertical lathe, etc to complete a single processing of nc machine tools, include vertical milling machining center, horizontal milling boring machining center, gantry boring and milling machining center, CNC milling boring machining center, CNC slitting machine tools to complete the composite processing of CNC machine tool equipment.Emerging edM machine, laser cutting machine, water cutting machine, wire cutting machine, parallel CNC machine, automatic compound machine production line.

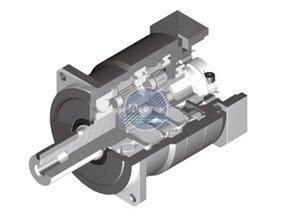

Motor parts

knife rest

Low end of the tool holder mainly through the motor torque to provide energy, mainly used in low precision requirements of machine tools

There are many kinds of middle tool holder, including hydraulic tool holder, servo tool holder and double electric tool holder.The pressure tool holder mainly USES hydraulic motor or hydraulic cylinder to provide energy, while the servo motor is used to provide energy, which has higher requirements on control and accuracy, faster rotation and higher repetitive positioning accuracy.This kind of tool holder has high cost performance and is widely used in common machine tools.

High-end tool rest has higher performance than the above two kinds of tool rest, which is suitable for high-precision machining and widely used in high-end equipment with high precision requirements.

Servo drive

Current loop

As the innermost loop of the system, the current loop is the bottom data sampling link of the entire servo system. The shorter the sampling period of the discrete current loop is, the higher the servo rigidity will be and the better the servo control performance will be.

Speed ring

Speed ring ensures that the motor speed is consistent with the command value and eliminates the influence of load torque disturbance on the motor speed.Compared with the actual speed of the feedback motor, the difference between the speed instruction and the feedback motor can directly generate the Q-axis command current to control the acceleration, deceleration or uniform speed of the motor, so that the actual speed of the motor is consistent with the command value.

Position ring

Position ring is the precise tracking of the position instruction by the actuator.

It can generate the speed instruction of the motor and make the motor accurately locate and track.By comparing the set target position with the actual position accurately positioned by the motor, the deviation is used to generate the speed instruction of the motor through the position regulator.

advantage

(1) Transmission accuracy and positioning accuracy:

Transmission accuracy and positioning accuracy of the feed transmission of CNC machine tools play a key role in the machining accuracy of the parts.Whether to point, linear control system, or contour control system, transmission accuracy and positioning accuracy are the main indicators to characterize the performance of CNC machine tools.

(2) Response speed:

Work table should be able to track instructions sensitively and accurately within the specified speed range, and carry out single step or continuous movement without losing or multi-step phenomenon during operation.

(3) No clearance transmission:

Feed system transmission clearance generally refers to the reverse clearance, that is, the reverse dead zone error, which exists in the whole transmission chain in each transmission pair, directly affects the machining accuracy of CNC machine tools;Therefore, the transmission clearance should be eliminated as far as possible to reduce the reverse dead zone error.

(4) Stable operation:

Stability is the most basic condition for the servo feed system to work normally, especially in the case of low speed feed without creep, and can adapt to the change of external load without resonance.The so-called feed system life, mainly refers to the maintenance of CNC machine tool transmission accuracy and positioning accuracy of the length of time, and the ability of each transmission component to maintain its original manufacturing accuracy.

(5) maintenance

Structure design of the feed system should be easy to maintain and reduce the maintenance work to the maximum extent to improve the utilization rate of the machine tool.

Spindle drive mode

(1) Subsection infinitely variable speed

Spindle motor drives spindle rotation through finite gear transmission, which is suitable for large CNC machines Beds, especially for strong cutting

(2) Belt transmission speed change

Spindle motor drives spindle rotation through synchronous belt transmission mode, which is suitable for small and medium-sized CNC machines,

the bed is especially in the case of high vibration resistance;

(3) Direct drive of motor

Spindle motor drives spindle rotation directly through the coupling or directly USES the motorized spindle, this transmission mode is suitable

In small CNC machine tools, especially in high precision machining.

● High quality AKJ1530 CO2 laser cutting machine

● ATC CNC Router with a horizontal spindle

● High quality AK30F fiber laser marking machine

● High quality AK20F laser fiber marking machine

● Big news: we're building a new factory

● Polish customer purchased AKM1530 high quality CNC engraving machine

● Heavy duty ATC CNC router with horizontal spindle AKM2030C

● Acctek exhibition footprint

● Cost-effective fiber laser cutting machine AKJ1530F1

● ACCTEK cnc router wishes everyone a Merry Christmas

Get a Free Quote Now!

Useful Link

Recommend Machine

Big discount

Headquarters: 3-1007, Minghu Plaza, No. 777 Minghu West Street,Jinan City / Branch: A2-1-1802, Hanyu Jingu, High-tech Zone, Jinan City

Factory: No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province

Copyright © Jinan AccTek Machinery Co.,Ltd