Type of laser cladding process

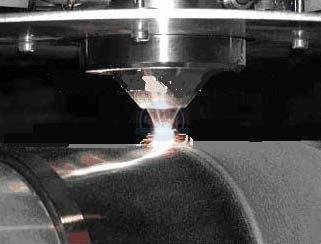

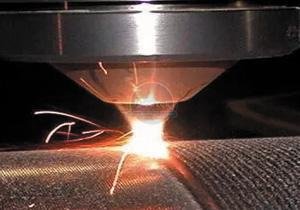

The laser cladding process can be divided into two types: one is feeding additive material before laser treatment, namely powder presetting method;The other is the synchronous feeding of materials during laser processing, namely the synchronous feeding method.Powder prefabricated laser cladding is a process in which the material is placed on the surface of the matrix material in advance and then melted by laser beam radiation scanning. The cladding material can be added in the form of powder, wire or plate, among which the form of powder is most commonly used.Powder presets were used in most of the studies.The main technological process of laser cladding with preset coating is: substrate cladding surface pretreatment, preset coating material, preheating, laser melting and post-heat treatment.Synchronous powder feeding laser cladding is used to direct the cladding material into the laser beam so that both the material supply and laser cladding can be completed at the same time.The cladding material is mainly sent in the form of powder, sometimes in the form of wire and plate for synchronous feeding.For parts with large cladding area, synchronous powder feeding method can be adopted.This method can adjust the amount of powder, and the synchronous powder feeder can work continuously, so the cladding efficiency is high, and it is suitable for the surface laser cladding of a large number of parts in actual production.The main technological process of synchronous powder feeding laser cladding is: substrate surface pretreatment, feeding laser melting, post-heat treatment.

Laser cladding process parameters

Laser cladding process parameters mainly include laser power P, spot size (diameter D or area S), laser scanning speed V, lap rate of multichannel lap or stop time of multilayer stacking, addition mode of coating material and protection mode, etc.The above technological parameters are the key factors to determine the macroscopic mechanical properties and microstructure of laser cladding coating.When D and V remain unchanged, with the increase of P, the coating density decreases gradually and the porosity increases gradually.The experimental results show that the technological parameters of laser cladding vary greatly with different powder types, quantities and particle sizes.

(1) Wear resistance

The wear resistance of laser cladding coating mainly depends on the properties, content and distribution of each phase of cladding layer.The wear resistance of the coating composed of single crystal WC is significantly lower than that of the coating composed of cast WC and sintered WC particles with the same particle size and content.The cladding layer has the best wear resistance when the WC content of single crystal is 35%, while the excessive WC content reduces the wear resistance of the cladding coating.For the cast WC particles, the wear resistance of the coating increases as the content increases.Nickel-based self-fusible alloy plays a bonding role in the composite coating, which makes the coating have high hardness and toughness at the same time, which is of great benefit to the improvement of wear resistance of the coating.The hardness and wear resistance of laser cladding metal-ceramic composite coating are not only related to ceramic phase type, particle size and distribution, but also closely related to laser cladding process parameters.The dissolution of WC significantly increases the content of W in the bonded metal, which is beneficial to improving the hardness of the bonded metal.At the same time, the slower the scanning speed is, the higher the dilution rate of the coating is, and the higher the dilution rate is, the lower the microhardness of the bonding metal will be.

(2) Corrosion resistance

The quality of laser cladding layer is mainly considered from two aspects.

1. Investigate the shape, surface roughness, cracks, pores and dilution rate of cladding channel;

2. Whether it is well organized and can provide the required performance.

In addition, the types and distribution of chemical elements in the surface cladding layer should be determined, attention should be paid to the analysis of whether the transition layer is metallurgical bonding, and if necessary, quality life testing should be carried out.

Crack is the most difficult problem in large area laser cladding technique.The main cause of the crack is the residual stress in the cladding layer, including thermal stress, structural stress and constraint stress.As a result of rapid heating of the laser beam, the cladding layer melt completely and micro cladding, the cladding layer and the substrate material between large temperature gradient, in the subsequent rapid solidification process, the formation temperature gradient and thermal expansion coefficient difference caused the cladding layer and substrate volume contraction, and in general, the shrinkage rate of cladding layer is greater than the substrate material, the cladding layer by the environment (in cold matrix) constraints, so the formation of tensile stress in cladding layer.Cracks occur when the local tensile stress exceeds the strength limit of the material.In fact, the solid metal is also affected by the structural stress caused by the martensitic phase transition in the matrix material during the cooling process.However, due to the great difference of volume shrinkage in the process of rapid solidification, the influence of thermal stress dominates.

In addition, the formation of cracks is also affected by many factors in the process of cladding, such as technological parameters, cladding layer and matrix material, cladding layer thickness and treatment technology.The laser heating and cooling speed is very fast, the molten pool exists for a very short time, so that the oxide, sulfide and other impurities in the cladding layer have no time to be released, and it is easy to form the crack source.When the cladding layer solidifies and crystallizes at an instant, dislocation and vacancy at grain boundary increase, atomic arrangement is irregular, defects of solidified structure increase, thermal brittleness increases, plastic toughness decreases, cracking sensitivity increases, and the cladding layer becomes thicker.

● High quality AKJ1530 CO2 laser cutting machine

● ATC CNC Router with a horizontal spindle

● High quality AK30F fiber laser marking machine

● High quality AK20F laser fiber marking machine

● Big news: we're building a new factory

● Polish customer purchased AKM1530 high quality CNC engraving machine

● Heavy duty ATC CNC router with horizontal spindle AKM2030C

● Acctek exhibition footprint

● Cost-effective fiber laser cutting machine AKJ1530F1

● ACCTEK cnc router wishes everyone a Merry Christmas

Get a Free Quote Now!

Useful Link

Recommend Machine

Big discount

Headquarters: 3-1007, Minghu Plaza, No. 777 Minghu West Street,Jinan City / Branch: A2-1-1802, Hanyu Jingu, High-tech Zone, Jinan City

Factory: No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province

Copyright © Jinan AccTek Machinery Co.,Ltd