Fan cleaning:

The use of the fan in the machine for a long time will accumulate a lot of solid dust inside the fan, so that the fan produces a lot of noise, is not conducive to exhaust and deodorization.When the fan suction is not enough to exhaust smoke, it is necessary to clean the fan.

Replacement of circulating water and cleaning of water tank:

Before the machine works, the laser tube must be filled with circulating water. The water quality and water temperature of circulating water directly affect the service life of the laser tube.Therefore, it is necessary to regularly replace the circulating water and clean the water tank.This is usually done once a week.

Lens cleaning:

There will be some mirrors and some focusing mirrors on the machine.The laser is reflected through these lenses, focused and then emitted from the laser head.The lens is easily stained with dust or other pollutants, resulting in laser loss or lens damage.So clean your lenses every day.

While cleaning, pay attention to:

1. The lens should be gently wiped and the surface coating should not be damaged;

2, wipe the process should be handled gently to prevent falling;

3. Please keep the concave face downward when installing the focusing mirror.

Fastening of screws and couplings:

Movement system in the work of a period of time, the movement of the screw, coupling will become loose, will affect the stability of mechanical movement, so in the machine operation to observe the transmission parts have abnormal sound or abnormal phenomenon, find the problem should be timely firm and maintenance.At the same time the machine should be hardened one by one with tools over time.The first hardening should take place about one month after the equipment has been used.

Guide rail cleaning:

Guide, straight spools as one of the core parts of the equipment, its function is to guide and support.In order to ensure the high machining precision of the machine, the guide rail and the straight line are required to have high guiding precision and good motion stability.During the operation of the equipment, a large amount of corrosive dust and smoke will be generated during the processing of the processed workpiece, which will deposit on the surface of the guide and the straight spools for a long time, greatly affecting the processing accuracy of the equipment, and forming corrosion points on the surface of the straight spools of the guide and shortening the service life of the equipment.So clean the machine guide rail every half a month.Turn off the machine before cleaning.

Optical circuit inspection:

Machine light path system is made up of mirror reflection, together with the focus lens focusing focus lens in the optical path was not found deviation problem, but the three mirrors is composed of mechanical part is fixed, the possibility of deviation is bigger, although usually does not happen, but suggest user before each work be sure to check the light path is normal.

● High quality AKJ1530 CO2 laser cutting machine

● ATC CNC Router with a horizontal spindle

● High quality AK30F fiber laser marking machine

● High quality AK20F laser fiber marking machine

● Big news: we're building a new factory

● Polish customer purchased AKM1530 high quality CNC engraving machine

● Heavy duty ATC CNC router with horizontal spindle AKM2030C

● Acctek exhibition footprint

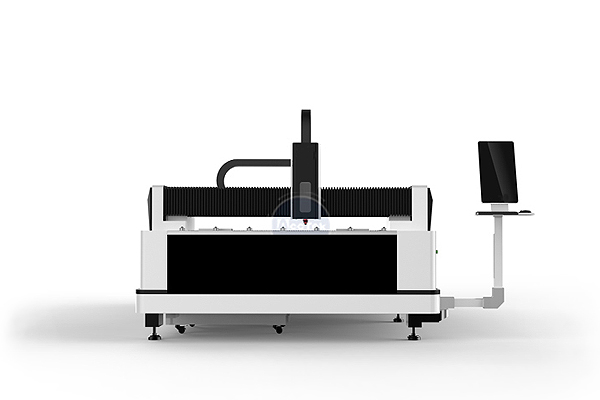

● Cost-effective fiber laser cutting machine AKJ1530F1

● ACCTEK cnc router wishes everyone a Merry Christmas

Get a Free Quote Now!

Useful Link

Recommend Machine

Big discount

Headquarters: 3-1007, Minghu Plaza, No. 777 Minghu West Street,Jinan City / Branch: A2-1-1802, Hanyu Jingu, High-tech Zone, Jinan City

Factory: No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province

Copyright © Jinan AccTek Machinery Co.,Ltd