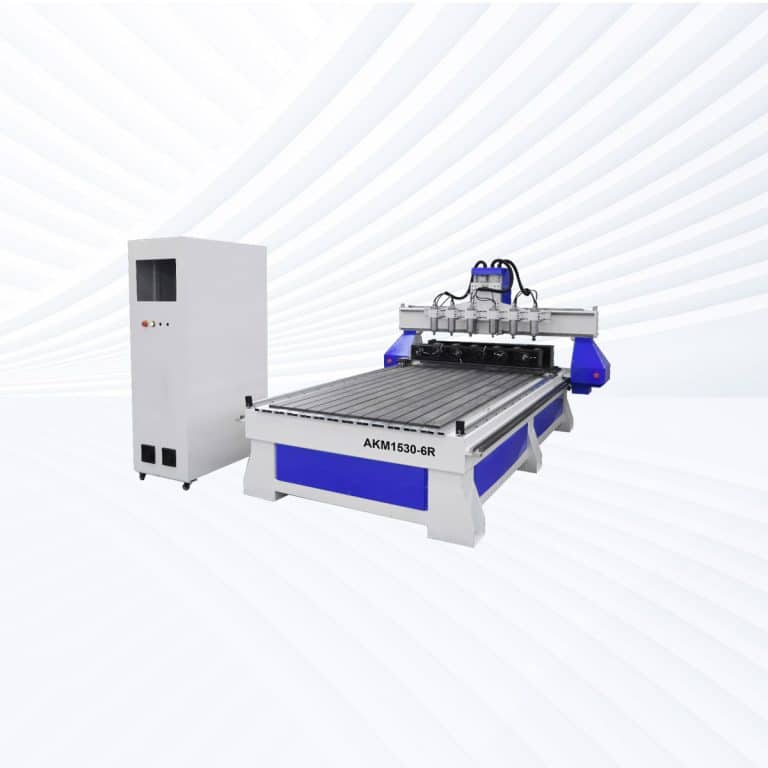

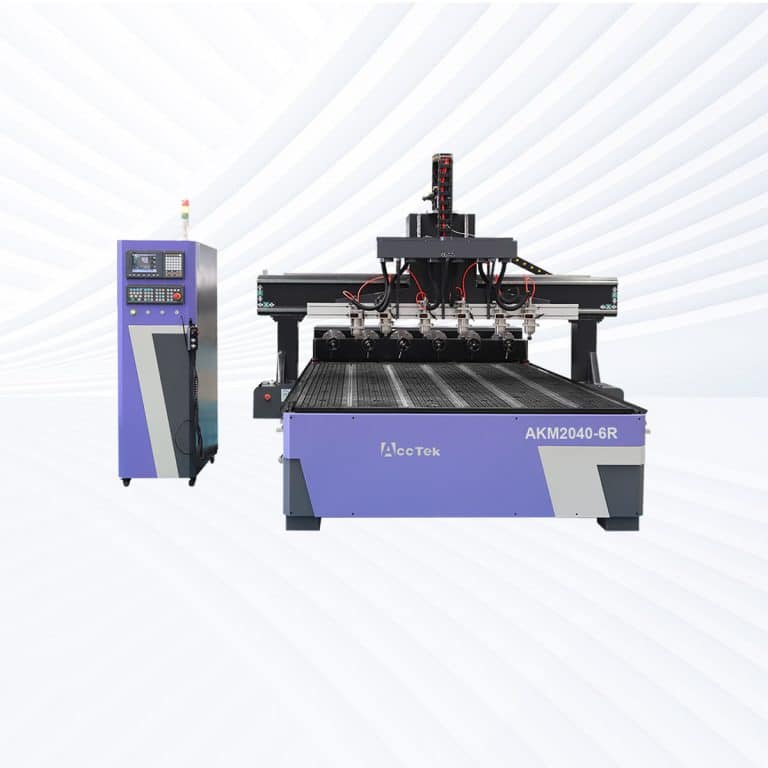

Product Introduction

Benefits of CNC Routing Rubber

High Precision and Accuracy

Rubber CNC routers ensure clean, accurate cuts without tearing or deformation, even on flexible materials. This level of precision is essential for manufacturing gaskets, seals, and custom components that require exact dimensions and reliable performance.

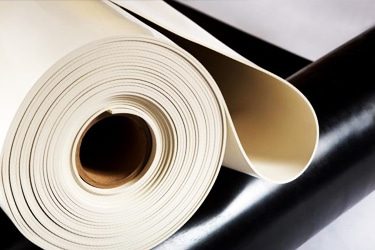

Versatility Across Rubber Types

From natural and synthetic rubber to silicone, neoprene, EPDM, nitrile, and foam rubber, CNC routers can process a wide range of rubber materials. This versatility allows manufacturers to expand product offerings across multiple industries and applications.

Improved Efficiency and Speed

CNC routers automate cutting and engraving tasks, completing complex jobs quickly compared to manual methods. This reduces labor costs, accelerates production cycles, and allows businesses to meet high-volume demands while maintaining consistent quality.

Consistency and Repeatability

Once programmed, CNC routers can reproduce designs with flawless consistency. This repeatability is critical for batch production of identical rubber parts, ensuring uniformity and reliability in products such as seals, gaskets, and vibration dampers.

Reduced Material Waste

Optimized toolpaths and precise cutting minimize errors and maximize material utilization. This reduces overall waste, lowers costs, and improves sustainability—especially important when working with specialty rubbers used in high-performance industries.

Expanded Design Flexibility

CNC routing makes it possible to create intricate shapes, detailed engravings, and complex patterns that are difficult to achieve manually. This flexibility supports innovation in product development, from industrial rubber components to custom-designed consumer products.

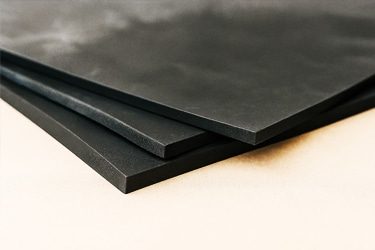

Compatible Rubber Materials

- Natural Rubber

- Styrene-Butadiene Rubber

- Nitrile Rubber

- Hydrogenated Nitrile Rubber

- Ethylene Propylene Diene Monomer

- Silicone Rubber

- Fluorosilicone Rubber

- Fluoroelastomer

- Chloroprene Rubber

- Butyl Rubber

- Halobutyl Rubber

- Polybutadiene Rubber

- Isoprene Rubber

- Polyurethane Rubber

- Thermoplastic Elastomers

- Thermoplastic Polyurethane

- Styrene-Ethylene-Butylene-Styrene

- Styrene-Isoprene-Styrene

- Chlorosulfonated Polyethylene

- Ethylene Propylene Rubber

- Acrylonitrile-Butadiene Rubber

- Epichlorohydrin Rubber

- Perfluoroelastomer

- Polychloroprene Rubber

- Thiokol

- Liquid Silicone Rubber

- Conductive Rubber

- Sponge Rubber

- Foam Rubber

- Natural Latex Rubber

- Reclaimed Rubber

- Recycled Rubber Sheets

- Hard Rubber

- Oil-Resistant Rubber

- Heat-Resistant Rubber

- Medical-Grade Silicone Rubber

- Food-Grade Silicone Rubber

- Automotive Rubber Compounds

- Marine Rubber Compounds

- Industrial Rubber Blends

Application of Rubber CNC Routers

Customer Testimonials

Comparison VS Other Engraving Technologies

| Feature | Rubber CNC Router | Laser Engraving | Hand Engraving | Chemical Etching |

|---|---|---|---|---|

| Cutting Depth | Adjustable, deep 2D & 3D | Shallow, risk of burning | Variable, limited by hand force | Very shallow, surface-only |

| Precision | High accuracy, smooth edges | Fine detail but may melt/deform | Inconsistent, artisan-dependent | Moderate, mask-dependent |

| Speed | Fast for large or complex projects | Fast for surface markings only | Slow, labor-intensive | Moderate, multi-step process |

| Material Compatibility | Works with most rubbers (NR, NBR, EPDM, Silicone, etc.) | Limited, heat-sensitive materials degrade | Any workable rubber, very slow | Poor, chemicals ineffective on many rubbers |

| Complex Designs | Handles intricate shapes & engravings | Best for 2D detail, limited depth | Limited by hand skill | Restricted to flat, masked designs |

| Repeatability | Perfect with CAD/CAM files | Repeatable for surface-only | Hard to replicate identically | Repeatable once masks are fixed |

| Setup Requirements | CAD/CAM software, tooling | Software, laser calibration | No setup, only tools | Masking, chemical handling & safety |

| Learning Curve | Moderate, training needed | Moderate, software-based | Very steep, years of practice | Moderate, process-sensitive |

| Production Volume | Excellent for prototypes & mass production | Medium-scale surface jobs | Not suitable for volume work | Limited, batch process only |

| Surface Finish | Clean, tear-free edges | Burned or hardened edges possible | Rough, hand-textured finish | Matte finish, poor clarity |

| Durability of Work | Long-lasting, structural parts | Surface-only, may wear off | Durable but inconsistent | Shallow, not durable |

| Customization | Quick digital adjustments | Easy file changes | Manual, slow adjustments | Requires new masks |

| Waste & Safety | Minimal waste, safe with dust control | Minimal waste, toxic fumes possible | No waste, but slow & tiring | Hazardous chemicals, disposal required |

| Cost Efficiency | Higher upfront, low per-part | Moderate cost, limited for rubber | Low tool cost, high labor | Low machine cost, high chemical use |

| Best Use Case | Gaskets, seals, pads, industrial rubber parts | Logos, shallow marks, barcodes | Artistic, unique one-offs | Industrial coding, not rubber-friendly |

Why Choose Us

High Precision & Efficiency

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Robust and Durable Design

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Intelligent Control Systems

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

Flexible Customization

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

Related Resources

Stepper Motor VS Servo Motor

This article compares stepper motors and servo motors, detailing their working principles, performance characteristics, applications, and key differences in modern automation.

How to Choose the Right CNC Router Spindle

This article explains how to choose the right CNC router spindle by detailing key factors such as power, torque, speed range, cooling type, precision, and machine compatibility.

What Are Vacuum Tables

This article explains vacuum tables in CNC routing, covering their components, types, benefits, applications, and maintenance, offering insights into their role in enhancing machining precision and efficiency.

Water-Cooled Spindle VS Air-Cooled Spindle

Compare water-cooled and air-cooled CNC router spindles in this guide. Covers function, performance, cost, maintenance, installation, safety, and material use cases.

Frequently Asked Questions

How Much Do Rubber CNC Routers Cost?

- 3-Axis CNC Routers: $3,000 – $10,000. These are entry-level machines ideal for flat rubber sheet cutting, gasket production, and simple engraving. They are affordable, easy to use, and well-suited for small workshops or businesses focusing on standard rubber products. However, they lack the flexibility needed for more complex 3D rubber shaping.

- 4-Axis CNC Routers: $12,000 – $22,000. Adding a rotary axis allows these machines to process cylindrical or curved rubber components, such as seals, rollers, or custom molds. The additional functionality comes at a higher cost, but it significantly expands application possibilities for medium-scale manufacturing.

- 5-Axis CNC Routers: $57,000 – $70,000. High-end 5-axis CNC routers provide the ability to cut rubber from multiple angles, creating highly complex shapes and molds. These machines are most often used in industrial production where precision and efficiency are critical. Their cost reflects advanced motion systems, stronger spindles, and expanded flexibility.

- ATC (Automatic Tool Changer) CNC Routers: $8,000 – $25,000. CNC routers with automatic tool changers are designed for higher efficiency, especially in production environments where multiple tools are needed for cutting, engraving, and finishing rubber in one setup. By reducing downtime, ATC CNC routers are highly effective for medium to large-scale rubber processing.

Is CNC Routing Rubber Safe?

- Dust and Particles: Routing rubber usually produces chips or fine shavings rather than hazardous dust like ceramics or composites. While less dangerous, small particles can still irritate skin and lungs. Using dust extraction and wearing protective masks ensures a cleaner, safer workspace.

- Fume and Odor Risks: Not all rubbers are safe to machine. Natural rubber and rubber approved for machining pose little risk, but rubbers containing chlorine (such as PVC-based rubber) release toxic gases when cut. Proper material selection is critical, and if synthetic rubbers are used, strong ventilation or fume extraction is essential.

- Heat and Fire Hazards: Rubber is prone to heating, softening, or even burning if feeds and speeds are not properly set. Dull tools increase friction, raising fire risk. Keeping tools sharp, adjusting cutting parameters, and never leaving the machine unattended reduce these dangers.

- Workholding Challenges: Rubber is flexible and can deform under tool pressure, leading to movement or inaccurate cuts. Secure fixturing with vacuum tables, clamps, or adhesive mats is necessary to prevent slipping. Incorrect workholding can also cause tools to bind or break.

- Noise and Vibration: Cutting rubber can generate vibration, especially when processing thick or dense sheets. This increases noise levels and may affect cut quality. Operators should wear hearing protection and ensure machines are properly calibrated.

- Tool Wear: Rubber is softer than many materials, but its elasticity can cause friction and clogging in router bits, leading to premature tool wear. Specialized tooling, such as compression or spiral bits designed for soft materials, minimizes clogging and improves safety.

What Are The Disadvantages Of Rubber CNC Routers?

- Material Flexibility and Deformation: Rubber’s elastic nature makes it difficult to machine cleanly. Unlike rigid materials, it can stretch, compress, or deform under cutting forces, leading to inaccurate dimensions and rough edges. Achieving precision often requires special tooling and slower machining speeds.

- Tool Clogging and Wear: Rubber tends to clog cutting tools, especially if improper bits are used. This increases friction and heat, accelerating tool wear. Even with sharp tools, the sticky nature of rubber can reduce efficiency and require frequent tool cleaning or replacement.

- Heat and Burning Risks: If cutting parameters are not optimized, rubber can heat up, melt, or burn during routing. This creates unpleasant odors and potentially hazardous fumes. Heat buildup also degrades the material’s edge quality and can damage tools over time.

- Dust, Odor, and Fume Concerns: Certain synthetic rubbers, especially those containing chlorine, release toxic gases when machined. Even safe rubbers can produce strong odors and fine particles that are unpleasant or irritating. Effective dust and fume extraction systems are required for safe operation.

- Workholding Challenges: Because rubber is flexible, securing it firmly during machining can be difficult. Standard clamps may cause distortion, while inadequate hold-downs lead to vibration and shifting. Specialized fixturing, such as vacuum tables or adhesive mats, is often necessary.

- Surface Finish Limitations: CNC routers may struggle to produce smooth, sharp edges on rubber parts without secondary finishing. Rough edges, tearing, or fraying are common issues, especially with softer grades of rubber.

- Slower Machining Speeds: To minimize deformation, clogging, and heat, rubber must often be machined at slower feed rates compared to rigid materials. This increases cycle times and reduces overall production efficiency.

- Higher Maintenance Demands: The combination of tool wear, dust, and sticky residue from rubber requires more frequent cleaning and machine maintenance. Without consistent upkeep, performance and precision quickly decline.

What Is The Life Expectancy Of Rubber CNC Routers?

- Entry-Level CNC Routers (5–8 Years): Basic 3-axis CNC routers designed for light-duty rubber cutting or engraving typically last 5–8 years. They are sufficient for small workshops producing gaskets or seals. However, frequent tool changes and cleaning are necessary to prevent premature wear from residue buildup.

- Mid-Range Professional CNC Routers (8–12 Years): CNC routers with stronger frames, better spindles, and more advanced dust collection can last 8–12 years under regular use. These machines handle daily production of rubber sheets, custom components, and larger batch orders with consistent performance when properly maintained.

- Industrial-Grade CNC Routers (15–20+ Years): Heavy-duty 4-axis and 5-axis machines equipped with servo motors, ATC (Automatic Tool Changers), and sealed dust systems can last 15–20 years or more. They are built for demanding environments where rubber processing is a core part of production. With proper care, these machines remain accurate and reliable for decades.

- Spindle and Tool Life (2–5 Years): Spindles and cutting tools experience the most stress when machining rubber. High-friction contact and residue buildup shorten spindle bearing life, requiring replacement every 2–5 years, depending on workload. Specialized tooling for rubber also wears faster and must be replaced regularly to maintain cut quality.

- Impact of Maintenance: The life expectancy of rubber CNC routers is strongly tied to maintenance practices. Regular cleaning of dust collection systems, lubrication of moving parts, and timely replacement of spindles and tooling extend overall service life. Neglecting these tasks leads to early breakdowns and costly repairs.

- Upgradability: Many professional and industrial CNC routers can outlast their original electronics. By upgrading control systems, motors, or spindles, users can keep machines productive well beyond their initial lifespan, especially in high-volume rubber machining applications.

How Do I Purchase Rubber CNC Routers?

- Define Application Needs: Start by identifying what kind of rubber products you plan to produce. For simple gasket cutting or flat sheet work, a 3-axis CNC router may be sufficient. If you need cylindrical, curved, or complex 3D parts, a 4-axis or 5-axis CNC router is more appropriate. Choosing the right axis configuration ensures efficiency and avoids overpaying for unnecessary features.

- Select the Right Machine Features: Consider spindle power, cooling method, and motor system. For small-scale operations, stepper-driven CNC routers with air-cooled spindles are cost-effective. For industrial use, servo motors and water-cooled spindles provide greater precision and durability. Automatic Tool Changer (ATC) models improve productivity for multi-step machining.

- Check Dust and Fume Control: Rubber can release strong odors or even hazardous fumes, depending on the material. A CNC router with proper dust extraction, sealed work areas, or optional fume collection is essential for safe and efficient operation. Confirm that the system meets workplace safety standards.

- Evaluate Software and Compatibility: Look for machines compatible with widely used CAD/CAM software. Simple, user-friendly software is important for small workshops, while advanced packages with multi-axis toolpath programming are better for industrial applications.

- Workholding Options: Rubber’s flexibility makes fixturing challenging. When purchasing, ensure the CNC router supports vacuum tables, adhesive mats, or clamps designed for soft and flexible materials. Secure workholding improves cut accuracy and prevents tool damage.

- Compare Price Ranges:

- Entry-level 3-axis CNC routers ($3,000–10,000) are best for small workshops or gasket cutting.

- 4-axis machines ($12,000–22,000) add versatility for more complex parts.

- High-end 5-axis CNC routers ($57,000–70,000) suit industrial users making advanced rubber components.

- ATC CNC routers ($8,000–25,000) are ideal for batch production where efficiency matters.

- Choose a Reliable Supplier: Look for suppliers with experience in CNC machines for rubber or soft materials. A reputable manufacturer should provide training, installation support, spare parts, and after-sales service. Checking customer reviews, case studies, and warranty policies helps ensure long-term reliability.

- Plan for Maintenance and Operation Costs: Budget not just for the machine but also for tooling, replacement spindles, dust filters, and operator training. Rubber machining can be demanding on tools, so having consumables readily available is critical.

What Are The Environmental Requirements For Using Rubber CNC Routers?

- Ventilation and Fume Extraction: Routing rubber can release odors and, in some cases, harmful fumes—especially with synthetic or chlorine-based rubbers. A well-ventilated workspace with localized fume extraction is essential. For industrial setups, enclosed machines with HEPA and activated carbon filters provide added safety and air quality control.

- Dust and Chip Collection: Although rubber produces more shavings than fine dust, residue can accumulate and interfere with machine performance. A dust collection system or vacuum table should be in place to remove debris at the source, keeping the workspace clean and reducing fire risk.

- Temperature and Humidity Control: Rubber materials are sensitive to extreme heat or cold, which can affect flexibility and machinability. Maintaining a stable workshop temperature (18–26°C or 65–80°F) and moderate humidity levels ensures consistent cutting performance and reduces stress on the material and machine.

- Noise Management: CNC routing rubber generates noise, especially at higher spindle speeds. Industrial environments should incorporate sound-dampening enclosures or provide operators with hearing protection to maintain safe working conditions.

- Stable Flooring and Vibration Control: Rubber CNC routers require a stable, vibration-free foundation for accurate machining. Installing machines on solid flooring, away from heavy machinery that produces vibrations, improves precision and reduces tool wear.

- Clean and Dust-Free Electronics Environment: Rubber residue can infiltrate motors, electronics, and control boxes if not properly managed. Machines should be operated in a relatively dust-free area with sealed enclosures for sensitive components, preventing overheating or malfunction.

- Fire Safety Measures: Rubber machining can generate heat and, in rare cases, smoldering particles. Fire extinguishers (preferably Class A/B for combustible solids) should be easily accessible. Operators must never leave machines unattended during operation.

- Waste Disposal: Scrap rubber and residue should be collected and disposed of according to local regulations. Recycling may be possible depending on the type of rubber used, while synthetic rubbers with hazardous additives may require special disposal procedures.

What Training Is Required To Operate Rubber CNC Routers?

- Basic CNC Operation: Operators should learn how to power on, set up, and operate the CNC router. Training covers machine startup procedures, homing axes, setting work coordinates, and loading toolpaths. For rubber machining, this includes adjusting feeds, spindle speeds, and depth of cut to prevent material deformation or burning.

- CAD/CAM Software Skills: Understanding CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software is essential. Training includes designing rubber components, generating toolpaths, and simulating machining. For rubber-specific work, operators learn to optimize toolpaths for flexible materials to minimize tearing or stretching.

- Tool Selection and Maintenance: Operators must be trained in choosing appropriate tooling for rubber, such as compression or spiral bits that reduce clogging. Training also covers tool inspection, cleaning, and replacement to maintain cut quality and machine safety.

- Workholding and Fixturing: Because rubber is flexible, proper training in fixturing is critical. Operators learn how to secure rubber sheets with vacuum tables, adhesive mats, or specialized clamps. This reduces vibration, prevents movement, and ensures accurate cutting.

- Material Safety and Handling: Not all rubbers are safe to machine. Training should include material identification, safe handling practices, and recognition of hazardous rubber types that may release toxic fumes. Operators must understand when fume extraction or protective equipment is required.

- Dust and Fume Extraction Systems: Operators should be trained to operate and maintain dust and fume collection systems. This includes filter replacement, system checks, and troubleshooting to ensure a safe working environment when machining rubber.

- Machine Maintenance and Cleaning: Daily cleaning and routine maintenance are part of operator training. This involves removing rubber residue, lubricating moving parts, checking spindle condition, and inspecting belts and couplings. Preventive maintenance extends machine life and ensures safe operation.

- Safety Procedures and PPE: Training includes emergency stop use, fire safety protocols, and personal protective equipment (PPE). Operators should wear safety glasses, gloves, hearing protection, and masks when necessary to protect against particles, noise, and fumes.

- Advanced Training (Optional): For operators handling 4-axis or 5-axis rubber CNC routers, advanced training in multi-axis programming, toolpath simulation, and rotary machining may be required. Industrial users often provide in-house or manufacturer-led training to cover complex applications.

Does CNC Routing Rubber Require Auxiliary Equipment?

- Dust and Fume Extraction Systems: Routing rubber can release fine particles, sticky residue, and strong odors. Some synthetic rubbers may even emit harmful fumes. A dust and fume extraction system is essential for maintaining air quality and protecting both operators and machines. HEPA filtration and carbon filters are recommended for workshops handling larger volumes of rubber.

- Vacuum Tables and Workholding Fixtures: Because rubber is flexible and prone to shifting during machining, auxiliary workholding systems are critical. Vacuum tables provide even suction to keep sheets flat, while adhesive mats or custom fixtures prevent deformation. Without these systems, parts may move or stretch, reducing cut accuracy.

- Specialized Tooling: While not always considered auxiliary equipment, specialized router bits designed for rubber (such as compression or spiral bits) are often necessary. These minimize clogging, reduce heat buildup, and produce cleaner cuts. Some operations may also require tool cooling or lubrication systems to extend bit life.

- Cooling Systems: Water-cooled or mist-cooling systems can be used when routing thicker or heat-sensitive rubber. These reduce tool wear, prevent overheating, and minimize the risk of burning or melting edges. For high-speed production, cooling becomes especially important.

- Noise Reduction Equipment: Routing rubber can generate high noise levels, particularly in industrial setups. Auxiliary sound-dampening enclosures or barriers help maintain a safer, quieter working environment.

- Waste Collection and Disposal Systems: Auxiliary collection bins or conveyor systems may be needed in production environments. They help manage rubber shavings and offcuts efficiently, ensuring a clean workspace and compliance with waste disposal regulations.

- Software and Automation Upgrades: Some CNC routers benefit from auxiliary software upgrades for automated toolpath optimization or integration with Automatic Tool Changers (ATC). This improves efficiency when multiple steps are needed, especially in large-batch rubber production.