The problems that the

laser cutter should pay attention to when cutting round holes

In recent years, with the continuous development of laser cutters in China, more and more companies have begun to use laser cutters to cut round holes. It not only cuts a smooth section, but also changes the diameter of the hole at any time. It has high processing flexibility and is the only choice for cutting round holes.

Due to the flexibility and efficiency of laser cutting, traditional circular hole cutting has also begun to be realized on fiber laser cutting machines. The cut product is not only smooth in section, but also can be flexibly replaced to meet the diverse needs of the factory. However, laser cutting round holes is not as simple as we think, and the irregularities and deficiencies of round holes are also happening from time to time.

What if the hole is too small? The best method for laser cutter to cut round holes is that the ratio of round holes is 1:1, that is, the ratio of aperture to plate thickness is 1:1, that is, the larger the aperture, the better the cutting quality. Therefore, the quality of cutting round holes has certain requirements on the servo motor. The circular hole sometimes appears ellipse or irregular, which is related to the mismatch of the x-axis and y-axis movement. The direct cause of the mismatch between X-axis and Y-axis movement is improper adjustment of servo motor parameters. Otherwise, when the energy of the fiber laser cutter is insufficient, the cutting hole is likely to leave broken point residues and the round hole is not round.

In the blowing process, when the air pressure is too small, slag scratches and carbonization will appear on the furnace side, and the pressure is too high and it is easy to burst. Therefore, it is required that the process proofreader and the machine cooperate well, and the appropriate air pressure should be selected based on experience to make the cut round hole more full.

If the parameter error of the servo motor affects the cutting quality, the accuracy error of the guide rail and the lead screw will directly lead to the accuracy of the hole not reaching the expected level. This is related to the strength of laser cutter manufacturers.

Therefore, in the process of buying a laser cutter, you should try to choose high-quality, big-brand products. Pay attention to whether the parameters such as the accuracy and speed of the circular hole cutting of the laser cutter meet the standard requirements to determine whether the quality of the laser cutter purchased is qualified.

The relationship between

laser cutter quality and cutting speed

Laser cutters occupy a large area in the industrial manufacturing industry. Many metal materials, whether stainless steel, carbon steel or alloy materials, can be cut without deformation.

The optimal cutting speed range of the metal cutter can be determined according to equipment instructions or through experiments. Due to the difference in thickness, material, melting point, thermal conductivity and surface tension after melting, the cutting speed also changes.

In fact, the cutting speed of a laser cutter is very important. Determine the best cutting speed range according to equipment instructions or experiments. Due to the thickness of the material, different materials, melting point, thermal conductivity and surface tension after melting, the cutting speed also changes.

The main cutting advantages of metal laser cutter:

1. Appropriately increasing the cutting speed can improve the cutting quality. The incision is slightly reduced, the surface of the incision is smooth, and deformation can be reduced at the same time.

2. The cutting speed is too fast to make the cutting energy lower than the required value. The jet in the cutting seam cannot blow off the cutting fluid immediately, forming a great resistance. As the dross on the incision increases, the surface quality of the incision decreases.

3. When the cutting speed is too slow, the laser beam irradiates the surface of the material for a long time and the cut becomes wider. The molten material on both sides of the incision gathers and solidifies at the bottom edge, forming a slag that is not easy to clean. In addition, due to excessive heating and melting, the upper edge of the cut is rounded.

In order to meet the increasing requirements for quality and production efficiency in industrial production, we must pay attention to solving various key technologies and implementing quality standards, so that this new technology can be used more widely in our country.

The laser cutting material has no burrs, smooth surface and high precision, which is better than CNC punch and plasma cutting. It is understood that due to the slow cutting speed and poor cutting quality of fiber laser cutters, more attention should be paid to the maintenance and daily maintenance of laser cutting equipment. Only in this way can work efficiency, product quality and economic benefits be guaranteed to the utmost extent.

Many customers often ask how much your

laser cutter is? We can see the impact of price factors on customers' purchase intentions. The price of the laser cutter is based on the metal material to be processed, and the thickness and width of the metal are naturally different. The price of this machine is determined by its power. The higher the power, the higher the price. The larger the size of the metal, the greater the demand for machine tools and the higher the price. Therefore, in terms of price, we must first understand the relevant product configuration, and then ask the comparison of different manufacturers.

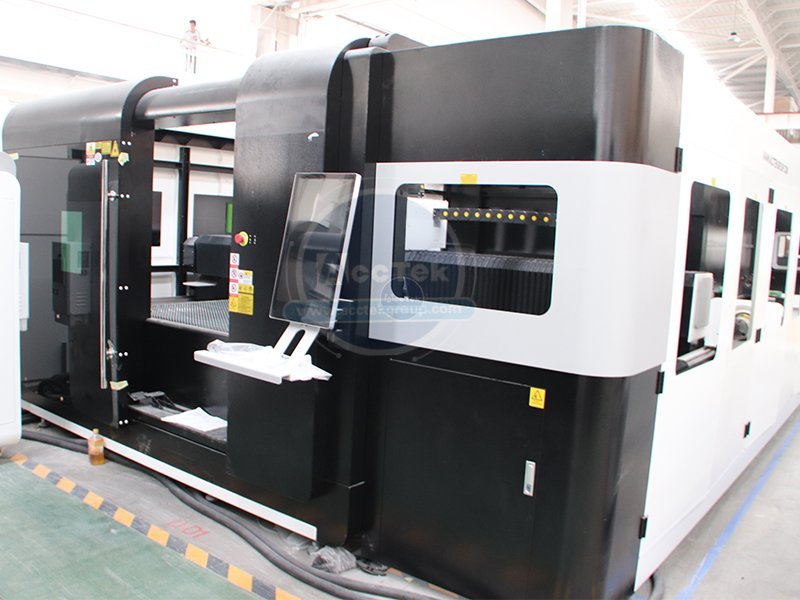

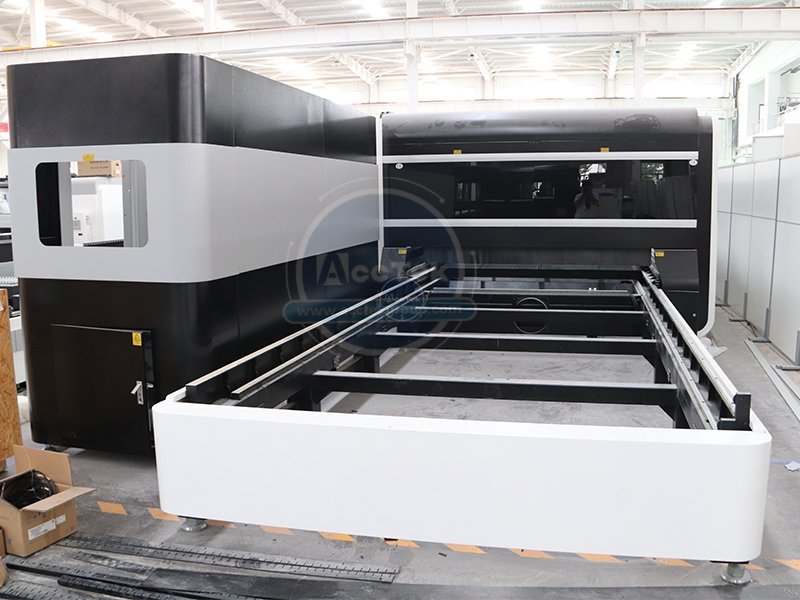

laser cutter:

1. High efficiency and low cost, specially designed for cutting medium and thick plates;

2. High performance, imported original fiber laser, stable performance;

3. Fast speed, improving work efficiency;

4. Stable and reliable optical system and control system;

5. High-quality and efficient cutting, smooth and beautiful cutting surface;

6. The whole machine is surrounded to reduce laser radiation, and the double workbench saves loading and unloading time;

7. It can cut plates and pipes, saving costs and high cost performance;