Cutting boards are one of the most useful and durable pieces of cardboard for cutting or cutting food.

Have you ever thought about using a personalized chopping board to cut/cut or give to a loved one?If not, then this time you can choose to do so.

You can make it a unique gift for a custom cutting board by adding various patterns or etching family photos.Laser machines help to satisfy your imagination and make it a reality.

Let's take a look at how chopper boards work.This sturdy cutting board can be completely customized.

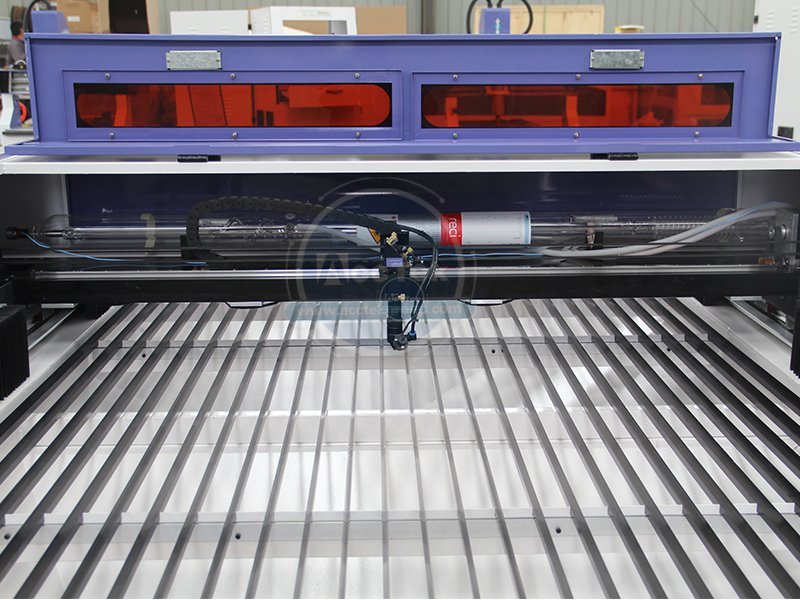

Laser machines offer a range of possibilities, with an unparalleled ability to carve and customize products made of metal and non-metal, including wood, ceramics, plastics, acrylic, etc.

The versatility and reliability of this device is still unmatched, and the ability to sculp products with amazing finishes is remarkable.Ease of use, high precision and high efficiency enable enterprises to produce their ideas and products.

To carve the oak logo in the wood, you need a CNC laser of 100 W CO2.Before starting the machine, configure the graphics software and program the design that you want to print directly on the product.It is very important to test the laser machine on similar materials to ensure the degree of combustion effect before actually working on the cutting plate.

Once you have the combustion effect guaranteed, you can begin the process of etching the design on the board of your choice.Also, you should choose the wood that is lighter in shade rather than deeper in shade.

The light-colored wood provides a clear mark for optimal visibility, while the deeper shadows mask the etching marks.If you want to burn deeper on your cutting board, you should choose a wood with a higher resin content, such as cherries or Art, while for lighter or minimal burns, you should choose a wood with a lower resin content.

Laser engraving is by far the best way to personalize wood.This is a very easy to operate and very efficient choice.After etching, the board is properly protected and cleaned by spraying vinegar on the board.Then wipe it with a clean cloth.Moisten the board with warm water and sprinkle with kosher salt.Wipe the salt with the lemon.

Follow this procedure and your cutting board will be kept clean and disinfected.

Because wood is an organic material, the markings on the wood are dark in color, which is caused by the carbonization of the material.The power required to etch wood is usually less than 10 watts.Watts are also different from hard and cork.

Hardwoods such as walnut, mahogany and maple produce good results, while cork needs careful etching.Cork needs proper power and makes cutting or etching faster.

Take a circular piece of wood about 3 inches in diameter and attach it to a board so that it doesn't vibrate and change its position.

Once you know the configuration of the laser machine, you can carve, etch, carve and cut numerous designs in a variety of materials.

Laser-cut Christmas ornaments have become very popular in recent years.You can mark all kinds of Christmas decorations to make your Christmas worth remembering.The wooden decorations were beautifully designed and well executed.They can enhance the look of the interior and make a huge difference to any interior atmosphere.

Some problems should be paid attention to in the use of

laser machine

When operating a laser engraving machine, etching, or cutting any material, you should wear anti-laser CARBON dioxide 10060 glasses to keep your eyes safe.Safety glass protects your eyes from dangerous reflections or scattered high-power laser radiation.

Laser eye wear block or attenuation appropriate wavelength range and optical density.It protects your eyes from direct or reflected light.

You should also remember to clean the laser glass with antifreeze in winter to protect the laser tube from damage.Also, when the machine is in an unheated garage, you should be careful not to leave water on the laser tube.

Monitor the laser tube regularly.Since the tube is not infinite and the power output is gradually reduced, it is important to replace the tube after a period of time.

In addition, you should also purchase a low-cost electricity meter and periodically check the power supply directly out of the laser tube.Once the meter reaches 65 percent of its rated power, you should plan to buy a replacement so that the work doesn't stop.

Finally, clean the lens and mirror of the laser machine regularly.Use a cotton ball or swab and moisten with propanol.Slowly wipe the elements with a regular pattern, not the surface.