In the field of metal manufacturing, stainless steel plate is a favorite material for users. The products manufactured by it have excellent performance in all aspects and relatively long service life, which are now widely used in machinery manufacturing, construction engineering, kitchenware manufacturing, rail vehicles and other industries.

Now most stainless steel processors choose to use

fiber laser machines for cutting, but if want to cut out high-quality thick plate stainless steel, it will need certain skills.

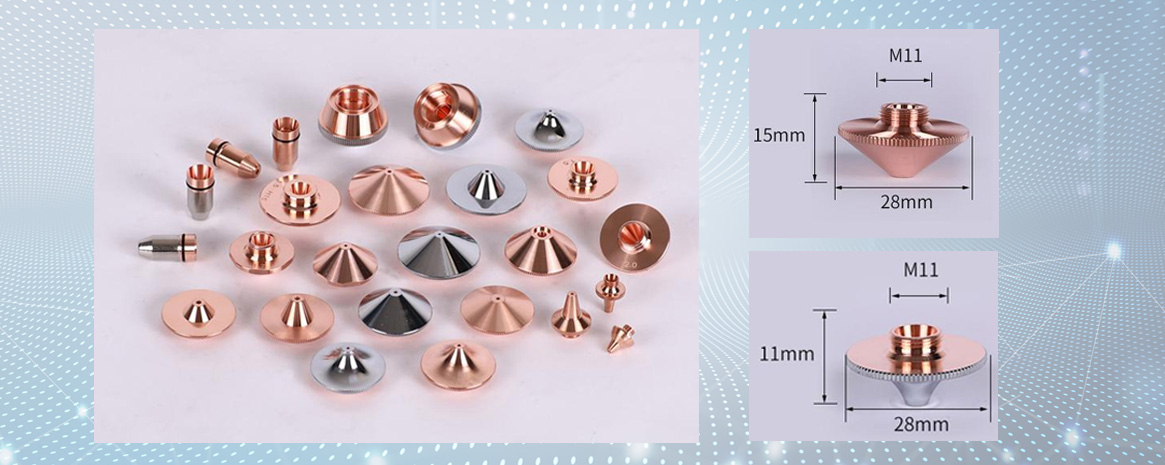

1. The selection of nozzle

The size of the nozzle diameter determines the shape of the airflow into the incision, the gas diffusion area, and the gas flow rate, which affects melt removal and cutting stability.

If the airflow into the incision is large, the speed is fast, and the position of the workpiece in the airflow is appropriate, thus the jetting ability to remove the molten material will be stronger.

The thicker the stainless steel, the larger the nozzle should be used, the higher the air pressure setting, the pressure and flow rate should be satisfied at the same time to cut a normal cross-section effect.

2. Frequency adjustment

The effect of frequency change on the cutting of stainless steel plate: the frequency decreases from 500 to 200Hz, the cutting cross-sectional effect becomes fine and layering slowly improves.

After frequency is set to 100Hz, it can not cut and become anti-blue light.

By changing the frequency, it can find the best frequency range.

To ensure the best cutting cross-section, it is necessary to ensure that the number of pulses and single pulse energy to perfectly match.

3. Focus selection

Different materials and thicknesses need to be adjusted to a different focus.

Before cutting, after measuring the actual zero focus, refer to cutting process parameters to determine the most suitable cutting focus faster.

4. Assist gas quality

Using oxygen to assist in the vaporization and expulsion of the molten material from the cut kerf is critical to thick steel plate cutting. Oxygen is an oxidizer that vigorously reacts when the laser beam makes contact with the metal. The pressure, volume and purity of the oxygen has the greatest effect on the speed at which both the metal is vaporized and expelled from the cut kerf. The purer the oxygen, the cleaner and faster the reaction is completed; subsequently, better edge qualities and faster feed rates can be achieved.

In the field of

metal cutting, fiber laser machines have irreplaceable advantages. Its processing range can cover almost all sheet metal parts. For the metal processing industry, choosing a suitable metal cutting machine is very important.

ACCTEK fiber laser cutting machine adopts RAYCUS/IPG laser source with has international advanced laser technology. Equipped with an Swiss Raytools brand auto-focusing cutting head, high-speed perforation and cutting of various material thickness.

ACCTEK has professional after-sales technicians who can give you the necessary help when operating the machine. Including the basic training before using the machine and the technical problems encountered during the operation, let these all be handed over to the technical team of ACCTEK.

The ACCTEK's product videos can be seen on Facebook and YouTube. Search for AccTek CNC on Facebook and AccTek China on Youtube. You can learn more about CNC knowledge.