When you choose to buy a

cnc router machine, the choice of configuration is very important. It not only affects the price you ultimately need to pay, but also determines the performance and functions of the machine.

Among the various accessories of the cnc router, the drive motor is the key factor. Choosing the right motor is critical for the efficiency and productivity of your motion control applications. It can be difficult to choose between servo motors and stepper motors as there are so many considerations: cost, torque, efficiency, speed, circuitry and more.

Servo motor and stepper motor can work well in the right situation, but knowing which one to go with can be a complex decision. It helps to first understand what differentiates these motors and the particular pros and cons each provides. You can then align the capabilities of the motor with the needs of your application.

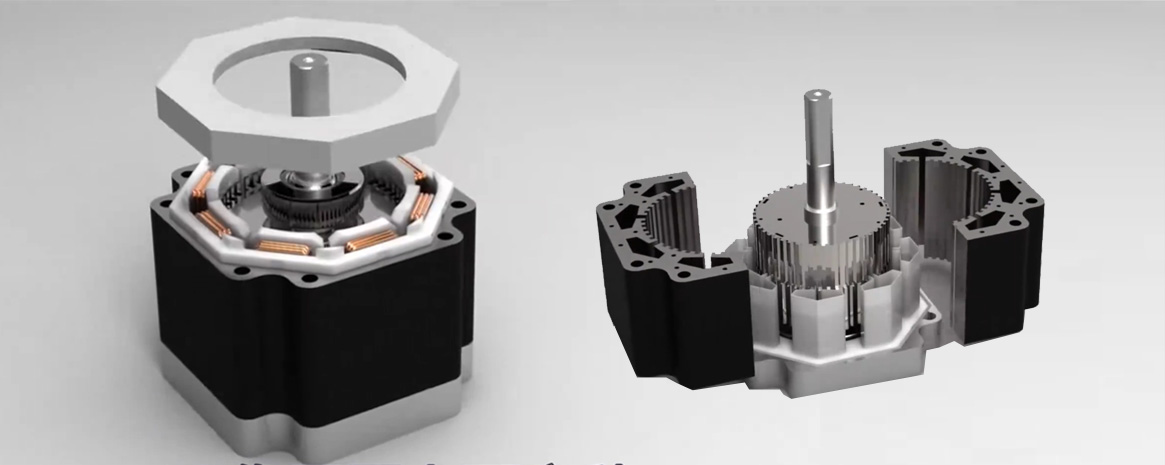

Stepper motors

Stepper motors generally provide the most value on small-footprint, small-work-envelope machines not in need of high speeds or torque. Most stepper motors run open-loop, which can help eliminate the added cost and complexity of adding an encoder or a resolver to the mix.

Stepper motors are capable of generating high torque at zero speed, but torque tends to decrease as speed increases. And speed limitations are commonplace with stepper motors, which generally operate most effectively at 1,200 RPM or lower.

From a high-level view, stepper motors can serve as a compact and economical solution that is dependable for small-machine applications.

The

conventional 3 axis cnc router produced by the ACCTEK factory is usually equipped with a stepper motor. It can meet the needs of normal engraving and cutting, and the price is cheaper. This type of cnc router machine is suitable for small woodworking shops, advertising industry or children's toy industry.

Servo motors

Once a CNC machine reaches a certain size and speed, it begins to require more power to work effectively. This is where servo motors come into play.

Servos are best for applications that require improved positioning precision and resolution. They run faster than stepper motors (usually at several thousand RPMs) and also provide more consistent torque across the entire speed range of the machine.

Servo motors have many advantages, but a major drawback is that they are more expensive than stepper motors.

In many of our CNC Router machines, we use Taiwan Delta servo motors and Japanese Yaskawa servo motors, which are also used by many of the finest machine tool builders in the world.

The High end

automatic tool-changing cnc router AKM1325C3 produced by our factory is equipped with Japanese Yaskawa servo motors, which greatly shortens the setting time, realizes acceleration and deceleration at high speed, and has fast response. It has resonance suppression function to ensure that the machine runs smoothly at high speed. Strong anti-interference ability and strong anti-overload capability.

Stepper motors and servo motors have their own advantages and application areas. If you don't know which configuration you should choose when buying an cnc router machine, our staff can provide you with free consulting services. Only by choosing the most suitable machine configuration, can the machine be maximized at the lowest price.