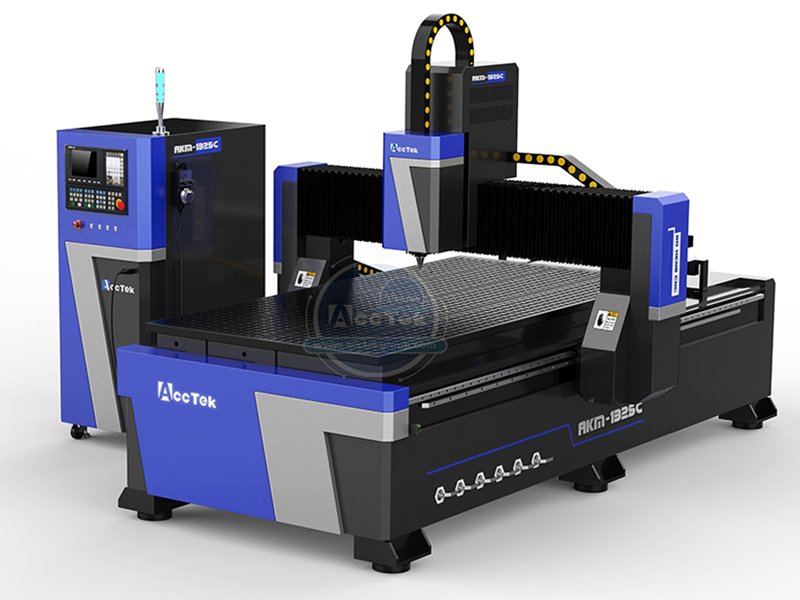

CNC woodworking engraving machine.No doubt, as anyone who has heard the name knows, this is for the production and processing of wood.But the NUMERICAL control engraving machine can not only carry on the simple production and the processing to the wood, but also can carry on the massive auxiliary production and the processing to the commodity.It could even be extended to other manufacturing industries.Below, it is necessary for people to see, woodworking CNC engraving machine can be used for what industry!

1. Carpentry

It is the most widely used woodworking CNC engraving machine industry, woodworking CNC engraving machine function.Different types and specifications can be different wood production and processing.The least is the production and processing of some common wood crafts.If the volume is larger, can carry on the production of large and medium-sized doors and Windows and processing.There are also technical expertise, such as the production and processing of mobile game tables, chairs and benches.It can be said that woodworking CNC engraving machine products have been widely used in People's Daily life.

2. Advertising

Woodworking CNC engraving machine can not only produce and process wood, but also be used in carpentry manufacturing industry.There is also a must use woodworking CNC engraving machine, namely advertising text industry, the use of woodworking CNC engraving machine can make some outdoor advertising light boxes, can also do some more prominent signs.Even some design and decorative products can be made according to the woodworking CNC engraving machine.And woodworking CNC engraving machine products more accurate, the key points to solve more timely.

In other words, woodworking CNC engraving machine can be used in the mold industry and some relief mold manufacturing.It can be said that woodworking CNC engraving machine application range is very wide, but it is also because woodworking CNC engraving machine can be on some common metal materials for production and processing.

During the use of woodworking, the CNC engraving machine shall check and maintain each part of the router according to the daily maintenance rules:

1. Guide rail lubricating oil tank: Check the oil level, oil quantity and lubricating oil pump for regular starting and stopping.

2. Clean the chips and dirt with THE CNC engraving machine on the guideway of Jinan XYZ axis, and check whether the lubricating oil is enough.

3. Heat dissipation and ventilation devices of various electrical cabinets: The cooling fans of each electrical cabinet work normally, and the air duct strainer is not blocked.

4. All kinds of protective devices: guide rail, machine tool protective sleeve, etc. Should not loose or leak.

5. Input/output unit of numerical control system: is the interface connected normally?

6. Pressure of compressed air source: Check the pressure of starting control system, which should be within the normal range.

7. Hydraulic balance system: the balance pressure indicator is normal, and the balance valve works normally when moving quickly.

8. Check whether the installation position of the tool is correct, whether the tool is sharp, whether it needs polishing, turn on the power, start the tool, and no abnormal idling.

9. Dimensional and mechanical errors shall be checked for formal operation.Check if there is enough cooling water for the NC engraving machine and rotate the equipment on the rough idle spindle for about 5 minutes.If the machine does not run for a long time, we need to run at full speed, running in time for about half an hour, it can be used normally.

1: stronger

Strength: "horsepower" of engraving machine.The main factor that affects the "horsepower" of engraving machine is spindle motor.The power of spindle motor is generally above 3000 W.The cutter may clamp its driving motor and driver.And these fittings also can affect woodworking engraving machine.

2: faster

In modern processing industry, a higher requirement is put forward for processing speed, that is, the study of processing efficiency.In can achieve intensity, can achieve how fast, can use how long under the premise, must choose strictly.High quality woodworking engraving machine is equipped with stepper motor or servo motor and large driver.While ensuring long time and fast processing, the drive system will not burn out and will not exceed the load of the engraving machine.

3: More accurate.

Precision is an important parameter of woodworking engraving machine.Woodworking carving machine to ensure high-speed processing and stability, high precision is not easy, but it is a high quality engraving machine essential talent, is also the inspection of engraving machine manufacturers consumption essential talent.No matter how long the carving and cutting task is, it will not be misplaced and the sculpting oil will be smooth and straight.

Reasonable structure, stable bed.

Bed span woodworking engraver must be sturdy and not out of shape.Mechanical woodworking engraving machine the entire bed after vibration aging stress relief.The machine is firm and does not change shape.It can fully adapt to long - term operation and maintain excellent performance and accuracy.