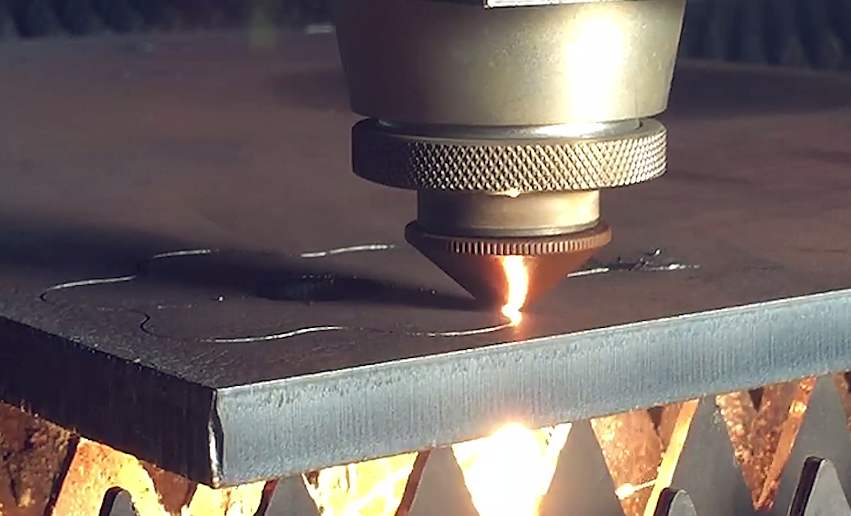

Optical fiber laser cutting machine /Co2 laser cutting machine

1. From the perspective of processing

On the one hand, THE CO2 laser cutting machine has a wide cutting range and can cut thick metal plates and aluminum plates and other highly reflective materials.For non-metallic materials such as acrylic, wood, PVC and other materials, CO2 laser cutting machine cutting thickness can reach 60 mm.And CO2 laser cutting machine is the use of continuous laser, cutting surface smooth, good cutting quality.

On the other hand, although the CO2 laser cutting machine is relatively thin, it is very slow in processing thick plates.In the thin plate processing, the same power fiber laser cutting machine than CO2 cutting speed is 2-3 times higher, smooth cutting section.In addition, the beam diverges greatly, so it is not suitable for processing in large scale.

2. From a cost perspective

In the process of using CO2 laser cutting machine, the processing cost of maintenance is relatively high, not only the front mirror tail mirror is expensive, but also the life of turbine bearings is only 8,000 hours, the replacement cost reaches 80,000 yuan per pair.At the same time, CO2 laser cutting machine will produce gas consumption, and photoelectric conversion rate is only 8-10%.The optical fiber laser cutting machine has no consumables, and the photoelectric conversion rate can reach 30%, which is more energy-saving and energy-saving.

3. From a maintenance perspective

The laser structure of CO2 laser cutting machine is complex, so it is inconvenient to maintain and has high operation requirements, while the fiber laser cutting machine is simple to maintain, and can be competent for the harsh working environment, with high tolerance to dust, shock, impact, humidity and temperature.

Fiber laser cutting machine /YAG laser cutting machine

1. From the perspective of processing

YAG laser cutting machine has low purchase cost and can cut high reflective materials, such as aluminum, copper and other optical fiber laser cutting machine can not cut non-ferrous metal materials.However, YAG laser cutting machine is almost the same kind of low-power laser cutting machine, which can only cut the thin plate material below 8 mm. Moreover, compared with optical fiber laser cutting machine, the cutting efficiency is much slower than that of optical fiber, and the efficiency is relatively low.Optical fiber laser technology can achieve very high power in very small packages, so it takes up less space and saves space.

2. From a cost perspective

YAG laser is a laser developed for decades, the technology is mature, so YAG laser cutting machine price is relatively cheap.But with the popularization of fiber laser, this advantage is getting weaker and weaker.In addition, YAG laser cutting machine processing power consumption

3. From a maintenance perspective

Because there is no optical lens in the resonator of fiber laser, it has the advantages of no regulation, no maintenance and high stability, so the device maintenance and replacement is relatively simple.This is the traditional YAG laser can not compare.

Generally speaking, the advantages of optical fiber laser cutting machine are obvious.However, three kinds of laser cutting machines have their own characteristics. In practical application, we should choose them reasonably according to our own cutting requirements and budget.

● Buy a better 5 axis cnc router machine for your shop

● The applicable scope of laser cutting machine

● Application and selection of laser cutting machine

● Principle and technology of laser cutting glass

● How to choose a cnc router

● How to deal with soot in laser cutting and the application field of laser cutting

● Acctek exhibition footprint

● ATC CNC Router with a horizontal spindle

● Polish customer purchased AKM1530 high quality CNC engraving machine

● High quality AKJ1530 CO2 laser cutting machine

Get a Free Quote Now!

Jinan AccTek Machinery Co.,Ltd

Headquarters:3-1007, Minghu Plaza, No. 777 Minghu West Street,Jinan City

Branch:A3-4-905, Hanyu Jingu, High-tech Zone, Jinan City

Factory:No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province( Postal code 251200)

Email:[email protected]

tel:+086-0531-86160023

video | Knowledge | Events and Support

Copyright © Jinan AccTek Machinery Co.,Ltd 版权所有 Power by DedeCms | XML MAP