● Heavy duty ATC CNC router with horizontal spindle AKM2030C

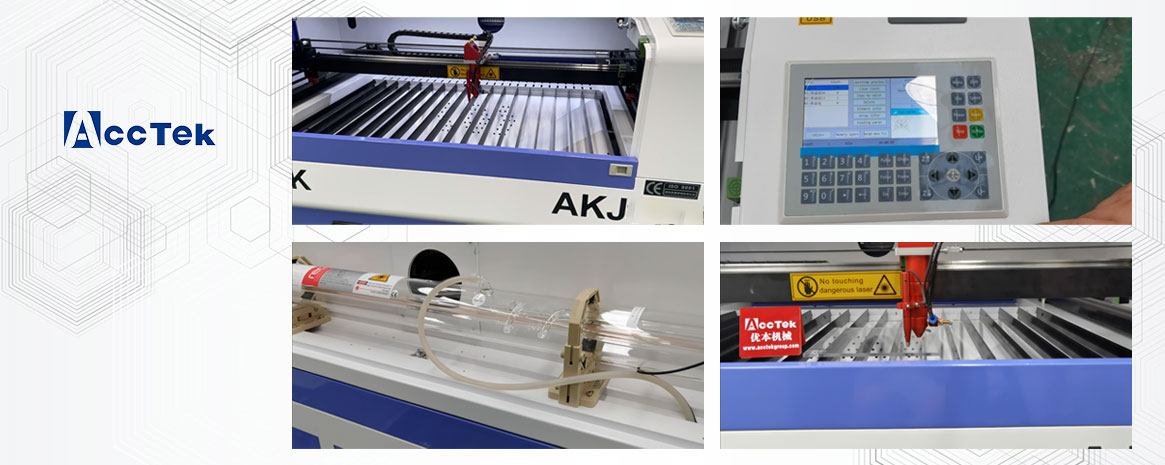

● High quality AKJ1530 CO2 laser cutting machine

● Buy a better 5 axis cnc router machine for your shop

● The applicable scope of laser cutting machine

● Application and selection of laser cutting machine

● Principle and technology of laser cutting glass

● How to choose a cnc router

● How to deal with soot in laser cutting and the application field of laser cutting

● Acctek exhibition footprint

● ATC CNC Router with a horizontal spindle

Get a Free Quote Now!

Useful Link

Recommend Machine

Big discount

Headquarters: 3-1007, Minghu Plaza, No. 777 Minghu West Street,Jinan City / Branch: A3-4-905, Hanyu Jingu, High-tech Zone, Jinan City

Factory: No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province( Postal code 251200)

Copyright © Jinan AccTek Machinery Co.,Ltd Power by DedeCms