The

laser machine is a kind of large-scale mechanical equipment, which has certain technicality and danger. And it is divided into laser engraving machine, laser cutting machine, laser marking machine.

There are also many kinds of laser cutting machines, and the more commonly used are CO2 laser cutting machines and fiber laser cutting machines.

In fact, according to the classification of different materials, it can also be divided into metal laser cutting machine and non-metal laser cutting machine. Generally speaking, CO2 laser cutting machine cuts non-metallic materials, fiber laser cutting machine cuts metal materials, and there are hybrid laser cutting machines, which can cut metal materials and non-metal materials.

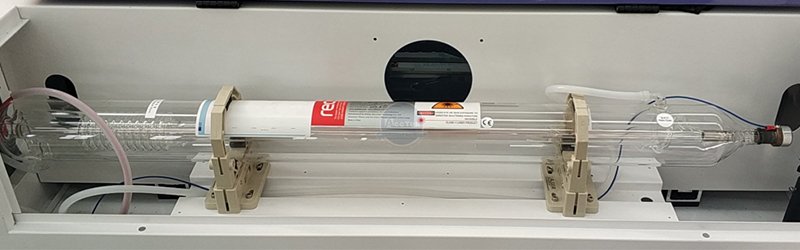

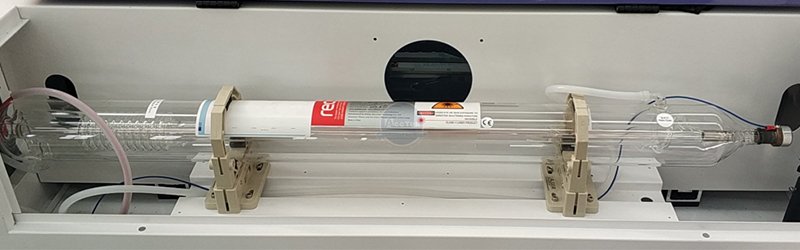

For CO2 laser cutting machine, the laser tube must be very important.

The Reci laser tube inlet is at the high pressure end (port facing down) and the water outlet is at the low pressure end (port facing up). The inlet and outlet of chengdu laser tube 80w is opposite to that of the hot spur. It is low in and out, the other is the same. There are two lines of positive (red) negative (black) at both ends of the laser tube, and the red line is a high voltage line.

Before processing, check that the water cooling system is working properly. If the laser tube is not full, do not start working, as high temperatures may cause damage to the laser tube. If there are air bubbles in the laser tube, please slowly rotate the laser tube to discharge all the air bubbles before using the laser tube; check if the accessories are installed correctly and operate normally; check the machine for abnormalities before placing the material for processing.

When we turn on the

laser machine, we also need to pay attention to some problems.

Notes

1. Using the machine for the first time, and please note that the machine working voltage of 220V.

2. Move up the laser head, ensure the limit line of head tube is cover inside the holder.so as to protect the laser head from crashing into the honey comb table while z-axis does reset/auto focus.

3. Please reset Z-axis after turn on the laser machine

4. Please don’t use the autofocus function if there’s no materials on the table.

Then we are about to start working, put the material on the work surface of the laser machine, and then you can use the auto focus function.

If

the machine does not have automatic focus finding function, firstly use the focal length block to adjust the appropriate focal length. The operation steps are as follows: Place the focal length block on the surface of the cutting material, and slowly lower the laser head so that the laser head just falls to the position of the focal length block.

This is the best focal length.If the machine has auto focus function, press the “focus” button to complete the auto focus。

Then the machine will cut according to the previously set pattern.

There are some minor problems that will not be revealed at the beginning, but after a long period of use, the machine may show some minor problems.

After a long period of use, the beam path may deflect. This will reduce the efficiency of the laser beam and even result in no laser beam. At this point, you need to re-adjust the light path。The laser light path diagram is shown below:

(1)Adjusting the position of the laser tube, the center of the laser tube emission end is at the same height as the center of the third mirror

(2)Reflecting mirror adjusting

Stick a piece of paper on ray inlet hole of laser head; then move the laser head to upper left coroner of the machine. Press “pulse” button and make a dot. Then move the head to the lower left corner of the machine to make another dot.

Using adjusting screw of the first reflecting mirror to make these two dots totally matched together, thus fix the ray path Y. Then turn to ray path X. Move the laser head to the left of crossbeam. Press “pulse” button to make a dot. Then move it to the rightto make another dot. Using adjusting screw of the second reflecting mirror to make these two dots totally matched together.

(3) Ray vertical adjusting

Put a piece of acrylic on the working platform. Press “pulse” button to see whether the pierced acrylic is vertical or not. If it is not vertical, adjust the mirror cover of the third reflecting mirror to make the ray vertical. Ray vertical adjusting is to adjust the ray position on condensing lens. Only the ray is in the center of condensing lens, can the it be straight and strong.