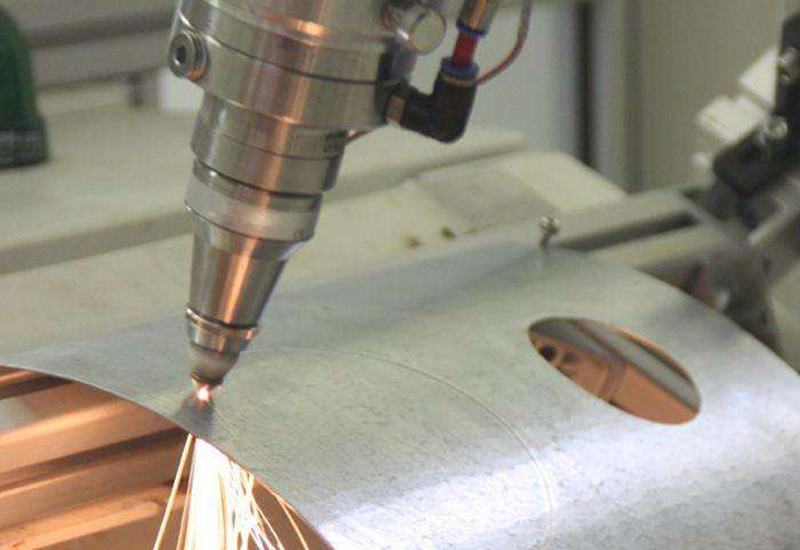

To master the law of various technological factors affecting the surface quality of laser cutting machine, we can find the way to improve the surface quality of technological measures, improve the surface quality of processing.For the majority of laser cutting processing, the evaluation of its processing quality mainly includes the following points:

1. Smooth cutting surface with few lines and no brittle fracture

When the laser cuts the plate at high temperature, the trace of the molten material will not appear in the incision under the vertical laser beam, but will come out at the back of the laser beam.As a result, curved lines are formed at the cutting edge, and the lines follow the moving laser beam closely. In order to correct this problem, reducing the feed rate at the end of cutting processing can greatly eliminate the lines.

2. Narrow slit width (this is mainly related to the diameter of laser beam spot and depends on the quality of laser tube)

Generally, the cutting width does not affect the cutting quality. Only when a particularly precise contour is formed inside the component, the cutting width has an important influence. This is because the cutting width determines the minimum internal longitude of the contour.Therefore, to ensure the same precision, no matter how wide the cut, the workpiece should be constant in the laser cutting machine processing area;

3. Good perpendicularity of the slit and small heat-affected area

When the thickness of the processed material exceeds 18mm, the verticality of the cutting edge is very important.Away from the focus, the beam diverges and the cut widens towards the top or bottom, depending on where the focus is.The cutting edge deviates from the vertical line by several millimeters. The more vertical the edge is, the higher the cutting quality is.

4. Influence of cutting material heat

As a thermal cutting processing application equipment, it is bound to have a thermal impact on the material in the process of use, which is mainly reflected in three aspects: A.B. Depression and corrosion;C. Material deformation

The heat affected area refers to the area near the incision that is heated in laser cutting.At the same time, the structure of the material itself changes.For example, some materials will harden.Heat affected region refers to the regional change of internal structure due to high temperature.But the concave and the corrosion are to the cutting edge surface has the adverse influence, affects the laser cutting machine appearance.They appear in general should avoid cutting errors;Finally, if the cutting causes the component to heat up sharply, it will deform.This is especially important in fine machining, where the contours and connectors are usually only a few tenths of a millimeter wide.Controlling laser power and using short laser pulses can reduce component heating and avoid deformation.

● Buy a better 5 axis cnc router machine for your shop

● The applicable scope of laser cutting machine

● Application and selection of laser cutting machine

● Principle and technology of laser cutting glass

● How to choose a cnc router

● How to deal with soot in laser cutting and the application field of laser cutting

● Acctek exhibition footprint

● ATC CNC Router with a horizontal spindle

● Polish customer purchased AKM1530 high quality CNC engraving machine

● High quality AKJ1530 CO2 laser cutting machine

Get a Free Quote Now!

Jinan AccTek Machinery Co.,Ltd

Headquarters:3-1007, Minghu Plaza, No. 777 Minghu West Street,Jinan City

Branch:A3-4-905, Hanyu Jingu, High-tech Zone, Jinan City

Factory:No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province( Postal code 251200)

Email:[email protected]

tel:+086-0531-86160023

video | Knowledge | Events and Support

Copyright © Jinan AccTek Machinery Co.,Ltd 版权所有 Power by DedeCms | XML MAP