This paper introduces how to judge the noise abnormality of the woodcutter, and the selection and application of the main shaft and cutting machine of the woodcutter.

How to judge whether the noise from engraving machine is abnormal?

There is a pause at each step and the noise is normal.At a certain frequency, the woodcarving machine will also produce a resonant body, sending out obvious noise.The noise will not affect the normal operation of the machine.Influential and harmful woodworking noise is mainly manifested in the following two types:

1.Abnormal noise is produced when the spindle motor is running.

This noise can be evidence of a quality problem with the spindle bearing, or the spindle bearing has reached its useful life, or the quality of the spindle bearing after wear or damage can be considered for replacement.

2).Abnormal noise during axial operation.This is happening mainly on the X-axis.

Most cases of operation damage of digital axial motor or loss of x axis guide of lubricating oil, too dirty, too tight, ball wear, ball fall off should be dealt with in time.

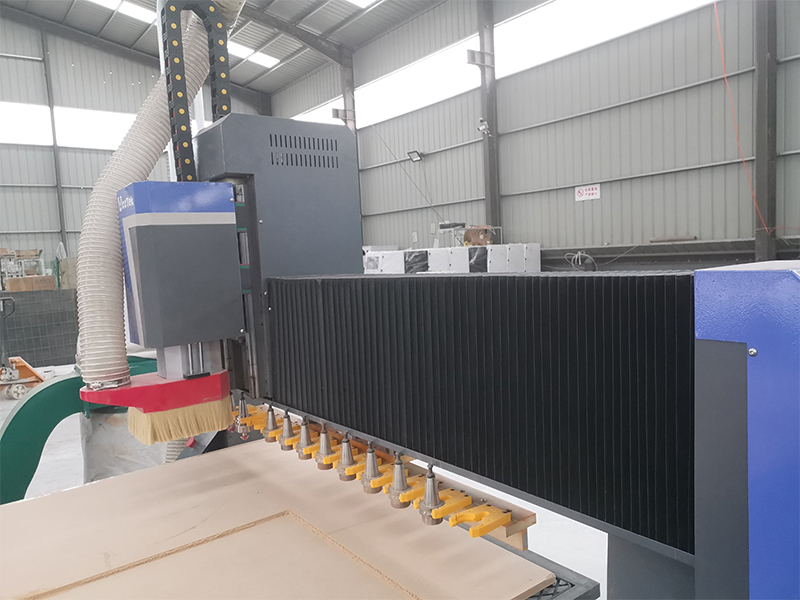

The main shaft of a woodcutter is the most important part of a woodcutter.The advantages and disadvantages of grooves directly affect the processing speed and precision of grooves machine.How to choose a high quality groove is very important.

1. If you want to pursue the processing efficiency of wood engraving machine, the processing should not only be rapid, but also a large number of tools, such as wood material processing, need more 3KW spindle motor.

If the intaglio machine spindle motor adopts high precision rolling, otherwise the performance is the spindle motor in high-speed rotation after a long time overheating, affecting the service life of the spindle motor.

3. Observe the gravure press spindle rotation at different speeds, especially at high speed rotation, the sound is uniform and harmonious.

(4).See if the main shaft of the engraving machine is valid.The main reference is the high speed cutting of hard materials.Some spindles cannot cut hard materials at extremely low speeds, otherwise the spindle's performance will be seriously damaged over time, affecting the spindle's accuracy and even accidents.

1. Sharp knife. This tool is characterized by a high precision machining, a good chip, and not easy to break the tip. Its processing efficiency and quality are ordinary knife mill can not grind.

2. Flat point flat knife lined with length, flat flat knife extra length-slicing. All adopt high quality hard alloy, all adopt digital control grinding, cutting-edge knife factory all optical passing detection, pass rate is 100%. This product is specially adapted for the finish of the multi-head engraving machine.

3. Single-edge acrylic moulding. High-capacity spiral shavings, Mirror blade grinding process design, combined with ultra-thin grain tungsten steel knife body, especially suitable for acrylic, PVC, plastic, cork, density plate and other high-yield lot production, non-stick knife in the processing process, smokeless, tasteless, silent, is a true green environmental carving tool.

4. Single-bladed solid woodcut. This tool adopts small spiral angle design, better chip discharge, back using fine rib, better stiffness, in the treatment of solid wood, high density plank, cutting strength is good, do not burn the knife. With the German body of ultrafine tungsten steel knife, the resistance to wear of the tool is very good, it is a high speed engraving in the treatment of solid wood can not see a good knife.

5, 3d cutting knife. This 3D knife is the latest 3D knife with great precision and wear resistance. Its quality is extraordinary. It's a real 3D knife with double edges.

7. Sharp round-bottomed knife. This engraving tool is the first choice of small precision, small deep relief, especially suitable for acrylic, hardwood, density panel, aluminum, copper fine relief treatment, high finish product accuracy is good, much better than the general ball head tool and lower knife treatment. The consistency of the tool is good, engraving machine, multi- head engraving machine is the best partner.

8, high density chip density plate milling cutter with double edge. This type of cutting tool is specially adapted for the treatment of medium and low density board, it has the characteristics of a good discharge of chips, no black knife, no combustion board, a high processing efficiency, it is a patent cutting tool especially for the treatment of density board and woodboard.

9. Super wide 3D knife. This tool is designed to solve the majority of 3D carving font users and design requirements, for our domestic sculpture art to a higher level of contribution.

10, combination of woodworking tools. This type of cutter is the first interchangeable carpenter in China. The imported tungsten steel blade is not allowed to be replaced in the matrix part. The resistance to abrasion is very good. All kinds of models can be customized.

11. High-precision column knife. Particularly suitable for PPM treatment, special plastic, lcd panel, etc.

12, no edge with double-edged milling. Sharp edge, suitable for acrylic treatment, anti-stick knife. Good value for money. Cons: The treatment of the strong finish of the product is not very good.

13. Super hard edge edge clippers milling. Solid wood with edge teeth, deeper than the regular PCB milling cutter, chip removal performance is very good, the body of the tool is strong and not easy to break, for chip removal for fine solid wood and non-stick super hard, hardwood, synthetic wood, has quite perfect cutting performance, it's the ordinary spiral milling cutter can't reach.

14, pc board single - cutting-edge screw grinder. This cutting tool is specially designed to solve the P plate, PMMA, ABS and other high viscosity, melting point of the plate cutting treatment, compared to the ordinary acrylic knife with single blade has a better amount of chip discharge and sharper edge, cutting design can also solve the problem of plaque in the treatment.

15. Composite blade. This type of carving tool can ensure no smudging on the upper and lower surface and no edge bursting during cutting and processing, particularly suitable for high density panel requirements, veneer board, PVC, hibisch board and other products. It is an ideal tool for CNC engraving of high quality woodwork.

16. Diamond knife. To solve super hard materials (marble, jade, granite, hardwood, copper aluminum and high hard synthetic materials) metal woodwork tool handle relief cutter.

● Buy a better 5 axis cnc router machine for your shop

● The applicable scope of laser cutting machine

● Application and selection of laser cutting machine

● Principle and technology of laser cutting glass

● How to choose a cnc router

● How to deal with soot in laser cutting and the application field of laser cutting

● Acctek exhibition footprint

● ATC CNC Router with a horizontal spindle

● Polish customer purchased AKM1530 high quality CNC engraving machine

● High quality AKJ1530 CO2 laser cutting machine

Get a Free Quote Now!

Jinan AccTek Machinery Co.,Ltd

Headquarters:3-1007, Minghu Plaza, No. 777 Minghu West Street,Jinan City

Branch:A3-4-905, Hanyu Jingu, High-tech Zone, Jinan City

Factory:No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province( Postal code 251200)

Email:[email protected]

tel:+086-0531-86160023

video | Knowledge | Events and Support

Copyright © Jinan AccTek Machinery Co.,Ltd 版权所有 Power by DedeCms | XML MAP